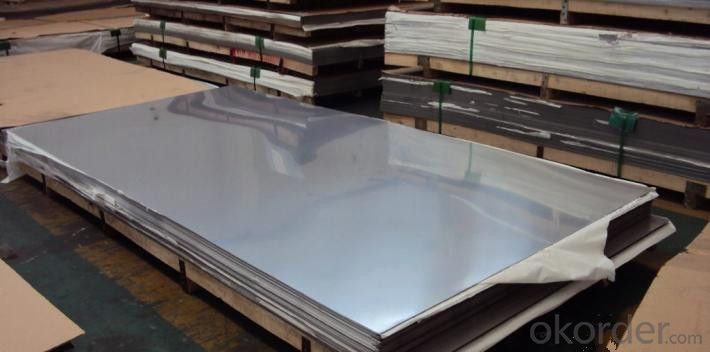

selling manufacturers stainless steel china 304 316 316l

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Best selling manufacturers stainless steel china 304 316 316l square pipe

All the materials are up to standard of GB, ROHS, SVCH.

We also accept the order of random length and other material's stainless steel pipes.

Our pipes are attractive and durable, that's the reason why we are the preferred supplier of Furniture, Handles, Sanitary Ware, and Medical Devices.

Product Details of Stainless Steel Pipe:

| Name | stainless tube |

| Standard | ASTM A554,A249,A269,A270,A312 |

| Material Grade | 201,202,304,316,316L,430 |

| Main Material | 201: Ni 0.8%~1%,202: Ni 3.5%~4.5%,304: Ni 8%,Cr 18%,316: Ni 10%,Cr 18%,316L: Ni 10%~14%,430: Cr 16%~18% |

| Outer Diameter | 8mm-76.2mm |

| Thickness | 0.5mm-1.5mm |

| Length | 6m or according to customers's request |

| Tolerance | a)Outer Diameter :+/- 0.1mm b) Thickness:+/- 0.02mm c) Length:+/- 5mm |

| Surface | 180G,240G,320G Hairline,400G,600G Mirror finish |

| Application | handrail,railing,staircase,weldmesh screen,door,window,balcony,fence,bench,furniture,ect. |

| Test | Squash test,extended test,water pressure teat,crystal rot test,heat treatment,NDT |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q:Are stainless steel bars suitable for structural applications?

- Stainless steel bars, without a doubt, are a fitting choice for structural purposes. This material, known for its versatility and durability, boasts exceptional strength and resistance against corrosion, making it an ideal option for structural applications. In construction, architecture, and engineering ventures where strength, stability, and longevity hold utmost importance, stainless steel bars are extensively utilized. Their elevated tensile strength and ability to endure severe environmental conditions contribute to their frequent use in the construction of bridges, buildings, and other structures. Moreover, the ease with which stainless steel bars can be fabricated and welded grants designers and builders ample flexibility in creating and assembling diverse structural components.

- Q:Are stainless steel bars suitable for offshore platforms?

- Yes, stainless steel bars are suitable for offshore platforms. Stainless steel offers excellent resistance to corrosion, making it a preferred material in harsh marine environments. It provides durability, strength, and reliability, making it suitable for various structural components and equipment on offshore platforms. Additionally, stainless steel's low maintenance requirements and long lifespan further contribute to its suitability for offshore applications.

- Q:What is the weight of a standard stainless steel bar?

- The weight of a standard stainless steel bar may change based on its size and quality. Nevertheless, a frequently employed standard stainless steel bar like ASTM A276/A479 Type 304 or 316 generally possesses a density of approximately 7.93 grams per cubic centimeter (g/cm³) or 7930 kilograms per cubic meter (kg/m³). To determine the weight of the bar, it is necessary to possess the measurements of its length, width, and height. This will enable the calculation of its volume, which can then be multiplied by the aforementioned density.

- Q:Do stainless steel bars have good formability?

- Yes, stainless steel bars generally have good formability. Stainless steel is known for its excellent ductility, meaning it can easily be shaped and formed into various shapes without cracking or breaking. This makes stainless steel bars a popular choice in industries such as construction, automotive, and manufacturing, where formability is a critical requirement. Additionally, stainless steel also offers good resistance to corrosion and high temperatures, further adding to its versatility and suitability for various applications.

- Q:Can stainless steel bars be used in the aerospace repair industry?

- Yes, stainless steel bars can be used in the aerospace repair industry. Stainless steel is known for its high strength, corrosion resistance, and durability, making it a suitable material for various aerospace applications. In the aerospace repair industry, stainless steel bars can be used for manufacturing and repairing various components, such as aircraft frames, engine parts, exhaust systems, landing gear, and other critical structures. The high strength-to-weight ratio of stainless steel bars makes them ideal for aerospace applications where lightweight yet strong materials are required. Additionally, stainless steel's resistance to corrosion and high temperatures ensures the longevity and reliability of the repaired parts. Overall, stainless steel bars are commonly used in the aerospace repair industry due to their exceptional mechanical properties and ability to withstand the demanding conditions of aerospace environments.

- Q:How do stainless steel bars resist alkaline solutions?

- Stainless steel bars resist alkaline solutions due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer prevents the corrosive effects of alkaline solutions, making stainless steel bars highly resistant to their damaging effects.

- Q:What industries commonly use stainless steel bars?

- Stainless steel bars possess exceptional properties and versatility, making them widely utilized in various industries. Construction and architecture heavily rely on these bars for the construction of buildings, bridges, and infrastructure. Their high strength, corrosion resistance, and durability make them ideal for such applications. The automotive industry also heavily depends on stainless steel bars for manufacturing engine components, exhaust systems, and chassis parts. Their resistance to heat, corrosion, and mechanical stress is crucial in this industry. Similarly, the aerospace industry utilizes stainless steel bars for the construction of aircraft components, offering excellent strength-to-weight ratios and resistance to extreme temperatures. The food and beverage industry commonly employs stainless steel bars in the production of food processing equipment and kitchen appliances. Their resistance to corrosion, easy cleanability, and aesthetic appeal make them suitable for these applications. Additionally, the pharmaceutical and chemical industries rely on stainless steel bars for equipment and storage vessels due to their exceptional resistance to corrosion. In the oil and gas industry, stainless steel bars are widely used in drilling operations, pipelines, and refineries. Their resistance to corrosion and high-pressure environments is essential in these applications. Similarly, the marine industry utilizes stainless steel bars for boat fittings, propellers, and offshore structures, as they can withstand the harsh and corrosive marine environment. In conclusion, stainless steel bars have a wide range of applications in industries such as construction, automotive, aerospace, food and beverage, pharmaceutical, chemical, oil and gas, and marine. Their unique combination of strength, corrosion resistance, durability, and aesthetic appeal make them the preferred material choice in these industries.

- Q:Are stainless steel bars suitable for pump shafts?

- Yes, stainless steel bars are suitable for pump shafts. Stainless steel offers excellent corrosion resistance, high strength, and durability, making it an ideal material for pump shafts that are exposed to harsh environments or corrosive fluids. Stainless steel also provides good dimensional stability and resistance to wear, ensuring reliable performance and a long service life for pump shafts.

- Q:What are the different types of stainless steel bar finishes for decorative purposes?

- There are several different types of stainless steel bar finishes that can be used for decorative purposes. These finishes are designed to enhance the appearance of the stainless steel and make it more visually appealing. One common type of finish is the brushed finish. This finish creates a subtle texture on the surface of the stainless steel, giving it a soft and matte appearance. It is achieved by brushing the stainless steel with a fine abrasive material, which removes any imperfections and creates a uniform finish. Another popular finish is the mirror finish. This finish creates a highly reflective surface that resembles a mirror. It is achieved by polishing the stainless steel with a series of progressively finer abrasives until a smooth and reflective surface is achieved. The mirror finish is often used in applications where a high level of shine and reflectivity is desired. A third type of finish is the bead blasted finish. This finish creates a textured surface that is achieved by blasting the stainless steel with small glass beads at high pressure. This process creates a uniform and matte finish that is often used to hide fingerprints and scratches. Additionally, there are other finishes such as the satin finish, which creates a smooth and low sheen surface, and the antique finish, which gives the stainless steel a weathered and aged appearance. Overall, the choice of stainless steel bar finish for decorative purposes depends on the desired aesthetic and the specific application. Each finish has its own unique characteristics and can be used to create different visual effects.

- Q:What is the difference between solid and hollow stainless steel bars?

- The structural composition and functionality are what differentiate solid stainless steel bars from hollow ones. Solid stainless steel bars, as their name suggests, are completely solid throughout their entire length. They are commonly used in applications where strength, durability, and load-bearing capacity are of utmost importance. Their robustness and ability to withstand heavy loads make them ideal for construction, engineering, and industrial purposes. Due to their solid nature, they provide excellent stability and resistance to bending or warping. On the other hand, hollow stainless steel bars have a void in the center, giving them a hollow core. This design feature offers several advantages, including reduced weight, increased flexibility, and improved heat dissipation. Hollow bars are often employed in applications where weight reduction is a priority, such as in the aerospace industry or for manufacturing lightweight structures. The internal void also allows for easy passage of wires, fluids, or gases, making hollow bars suitable for applications requiring internal routing or containment. Another important distinction between solid and hollow stainless steel bars lies in their cost. Solid bars generally require more material and undergo more extensive manufacturing processes, resulting in higher costs compared to hollow bars. However, the specific cost difference can vary based on factors like size, grade of stainless steel, and market conditions. It is worth noting that both solid and hollow stainless steel bars possess excellent corrosion resistance, a characteristic inherent to stainless steel. This resistance to corrosion is due to the presence of chromium, which forms a protective oxide layer on the surface, preventing rust and staining. Ultimately, the choice between solid and hollow stainless steel bars depends on the specific requirements of the application. If strength and load-bearing capacity are crucial, solid bars are the preferred option. Conversely, if weight reduction, flexibility, or internal routing is a priority, hollow bars offer a more suitable solution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

selling manufacturers stainless steel china 304 316 316l

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords