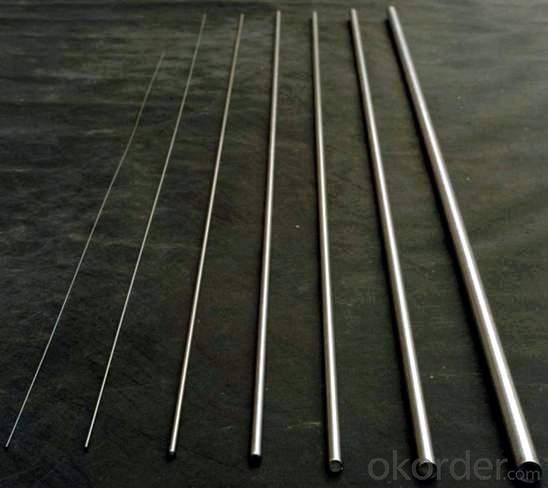

Stainless Steel Black Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 4000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Stainless Steel Black Bar:

Hot Rolled

DIA 10mmto 130mm

FORGE

DIA 130mm to 300mm

GB1220,ASTM A 484/484M, EN 10060/ DIN 1013

DIA 3mm to 60mm

INCH 1/8" to 2 1/4"

INCH 1/8" to 2 1/4"

Tolerance: GB1220, ISASTM A276/A 484M, EN 10278, DIN 671

Item | SS304,316L,420C,440C Stainless steel ball |

Category | Stainless Steel Ball |

Material | AISI 420 430 440 SS304 316L |

Size | 0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

Grade | G100-G3000 |

Hardness ( HRC) | HRC58-65 |

Application | Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

Standard | GB/T-308-2002, GB/T1148-93 |

Matched Standard | DIN, JIS, ASME |

Certification | ISO |

Packing | Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

Place of original | Shandong province, China |

Delivery | Within 30 days or confirmed while placing order |

Advantages of Stainless Steel Black Bar:

1. All products are made of high-quality imported raw materials.

2. Our products are certified by ISO9001:2008 authentication quality systems.

3. We are nominated as the AAA enterprise by Jiangsu government.

4. Quickest and most efficient Response to Your Enquiry.

Specifications of Stainless Steel Black Bar:

1.Features: Low density, high specific strength, high corrosion resistance, good thermal stability and plasticity.

2.It is widely applied for petroleum, chemical, mechanical and electrical, hardware, etc.

3.Quality assurance: All of the products are detected by ultrasound making sure that no defects inside the products. Besides, chemical composition, mechanical properties and high-powered organization are also strictly controlled, ensuring our clients get the best products.

Packing details of Stainless Steel Black Bar:

Products are well packed and clear labeled according to the regulations and customer's requests.

Intact packages are able to avoid any damage which might otherwise be caused during storage or transportation.

After service of Stainless Steel Black Bar:

1. One-year follow:

We’ll follow up and concern each order within a year. If there’re any problems of our order or product, you can contact us.

2. Quick reply:

If you find any quality problem after receiving the goods, you can contact us, we will manage and reply you in 48 hours.

- Q: Are stainless steel bars resistant to acetic acid corrosion?

- Yes, stainless steel bars are generally resistant to acetic acid corrosion.

- Q: Are stainless steel bars suitable for high-temperature furnaces?

- Yes, stainless steel bars are suitable for high-temperature furnaces. Stainless steel has excellent heat resistance properties, including high melting points and good oxidation resistance. It can withstand elevated temperatures without losing its structural integrity, making it a reliable material choice for high-temperature applications like furnaces.

- Q: Are stainless steel bars suitable for architectural facades?

- Architectural facades can indeed benefit from the use of stainless steel bars. This material is both durable and resistant to corrosion, which makes it perfect for external applications like facades. Its ability to withstand harsh weather conditions, UV radiation, and pollution ensures a long-lasting and low-maintenance solution for architectural projects. Moreover, stainless steel bars have a sleek and modern aesthetic that can enhance the overall design of a building. They can be utilized in different configurations and finishes to create distinctive and visually appealing facades. Due to their versatility and strength, stainless steel bars are highly favored by architects and designers for both residential and commercial projects.

- Q: Can stainless steel bars be used in marine vessel construction?

- Marine vessel construction can indeed utilize stainless steel bars. Due to its remarkable resistance to corrosion, stainless steel proves to be an ideal material for marine environments where constant exposure to saltwater and other corrosive elements occurs. Its exceptional strength and durability make it suitable for various structural components found in marine vessels. Stainless steel bars offer versatility as they can be utilized in the construction of hulls, decks, masts, railings, and other critical parts of the vessel. Moreover, stainless steel boasts good weldability and ease of workability, facilitating efficient construction processes. In summary, stainless steel bars are a favored option in marine vessel construction due to their corrosion resistance, strength, and versatility.

- Q: What are the different types of stainless steel bars used in food packaging?

- There are several different types of stainless steel bars used in food packaging due to their excellent corrosion resistance and hygienic properties. Some of the common types include: 1. Austenitic Stainless Steel Bars: These bars are highly corrosion-resistant and are the most commonly used type in food packaging. They have high levels of chromium and nickel, which provide excellent resistance to rust and stains. Austenitic stainless steel bars are also easy to clean and maintain, making them ideal for food contact surfaces. 2. Ferritic Stainless Steel Bars: Ferritic stainless steel bars have a higher amount of chromium and lower amounts of nickel compared to austenitic stainless steel. They offer good resistance to corrosion and can withstand high temperatures. Ferritic stainless steel bars are often used in food packaging equipment that requires heat resistance and durability. 3. Martensitic Stainless Steel Bars: Martensitic stainless steel bars have a higher carbon content, making them harder and more brittle compared to other types. They are commonly used in food packaging applications that require high strength and wear resistance. However, due to their lower corrosion resistance, they are often used in non-food contact areas. 4. Duplex Stainless Steel Bars: Duplex stainless steel bars have a combination of austenitic and ferritic properties, offering high strength and good resistance to corrosion. They are commonly used in food packaging equipment that requires both strength and corrosion resistance, such as storage tanks and processing machinery. When choosing the appropriate stainless steel bar for food packaging, it is crucial to consider factors such as corrosion resistance, hygiene, temperature resistance, and strength requirements, as each type of stainless steel bar has its own unique properties and advantages.

- Q: What are the different types of stainless steel bar surface treatments for improved cleanability?

- Improving the cleanability of stainless steel bars can be achieved through various types of surface treatments. These treatments include passivation, electropolishing, pickling, bead blasting, and powder coating. Passivation is a chemical treatment that eliminates iron particles and contaminants from the surface of stainless steel. By preventing rusting and corrosion, it simplifies the cleaning and maintenance process. Electropolishing, on the other hand, is an electrochemical process that eliminates a thin layer of metal from the stainless steel surface. This treatment results in a smooth and polished surface that is resistant to corrosion, making it easier to clean. Additionally, it minimizes microscopic imperfections, reducing the risk of bacterial growth. Pickling, a chemical treatment, is employed to eliminate impurities such as scale and discoloration from the stainless steel surface. It entails soaking the stainless steel in an acid solution, dissolving the impurities and leaving behind a clean and smooth surface. Bead blasting involves the high-pressure blasting of small glass beads or other abrasive materials onto the stainless steel surface. This treatment effectively removes dirt, rust, and other contaminants, resulting in a textured surface that is easier to clean and less prone to displaying fingerprints or scratches. Lastly, powder coating is a process wherein a dry powder is applied to the stainless steel surface and then heated to create a protective and durable coating. This treatment not only enhances cleanability but also improves the appearance of the stainless steel bar. Overall, these diverse surface treatments significantly enhance the cleanability of stainless steel bars by eliminating impurities, creating smooth and polished surfaces, and adding protective coatings.

- Q: Do stainless steel bars require any special handling during transportation?

- Yes, stainless steel bars do require special handling during transportation. They should be properly packaged and secured to prevent damage or scratching during transit. Additionally, special care needs to be taken to protect stainless steel bars from exposure to moisture or corrosive substances that might cause staining or rusting.

- Q: What is the difference between hot rolled and forged stainless steel bars?

- Hot rolled and forged stainless steel bars vary primarily in their manufacturing process and the resulting characteristics of the final product. Hot rolled bars are made by heating a stainless steel billet or ingot to a high temperature and then rolling it into the desired shape. This procedure creates a more uniform grain structure and enhances the mechanical properties of the steel. Hot rolled bars are generally less expensive and possess a coarser surface finish when compared to forged bars. Conversely, forged stainless steel bars are produced by heating a stainless steel billet or ingot to a high temperature and then subjecting it to intense pressure to shape the metal accordingly. This method yields a more refined grain structure and superior mechanical properties, such as increased strength, toughness, and resistance to wear and tear. Additionally, forged bars typically exhibit a smoother surface finish in comparison to hot rolled bars. In conclusion, the primary distinctions between hot rolled and forged stainless steel bars lie in their manufacturing process, resulting grain structure, and mechanical properties. Hot rolled bars offer cost-effectiveness and a coarser surface finish, whereas forged bars provide superior strength, toughness, and a smoother surface finish. The choice between the two depends on the specific application and the desired properties of the stainless steel bars.

- Q: What steelmaking furnace for stainless steel bars?

- At present, most with two kinds of stainless steel smelting furnace, a furnace is another electroslag furnace, intermediate frequency furnace is mainly used for less demanding occasions do not yield, while electroslag furnace materials used in the occasions with higher requirements.

- Q: Do stainless steel bars have good wear resistance?

- Yes, stainless steel bars have excellent wear resistance. Due to their high strength and durability, stainless steel bars are commonly used in applications where resistance to wear and tear is essential. The addition of chromium in stainless steel provides a protective layer that enhances its resistance to corrosion, abrasion, and impact. This makes stainless steel bars ideal for use in various industries such as construction, automotive, aerospace, and manufacturing, where they are exposed to harsh environmental conditions and heavy usage. Additionally, stainless steel bars can retain their original shape and strength even after prolonged use, making them a reliable choice for applications requiring wear resistance.

Send your message to us

Stainless Steel Black Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 4000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords