Aluminum Round Bar Stock

Aluminum Round Bar Stock Related Searches

Round Aluminum Bar Stock Aluminum Bar Stock Round Aluminum Half Round Bar Stock Round Aluminum Stock Aluminum Round Bar Stock Sizes Aluminum Rectangular Bar Stock Aluminum Round Bar Stock Near Me Aluminum Square Bar Stock Round Stock Aluminum Solid Aluminum Bar Stock Bending Aluminum Bar Stock Stock Aluminum Bar Aluminum Stock Bar Aluminum Flat Bar Stock Aluminum Hollow Bar Stock Anodized Aluminum Bar Stock Aluminum Triangle Bar Stock Extruded Aluminum Bar Stock Aluminum Bar Stock For Sale Buy Aluminum Bar Stock Solid Aluminum Round Stock Aluminum Bar Stock Price Casting Aluminum Round Stock Cold Bending Aluminum Bar Stock Aluminum Tee Bar Stock Polished Aluminum Bar Stock Metric Aluminum Bar Stock Aluminum T Bar Stock 1 2 Aluminum Round Stock 1 2 Aluminum Bar StockAluminum Round Bar Stock Supplier & Manufacturer from China

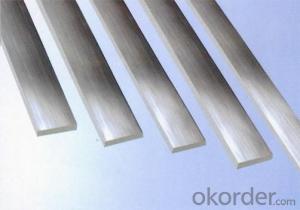

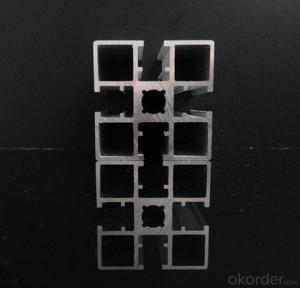

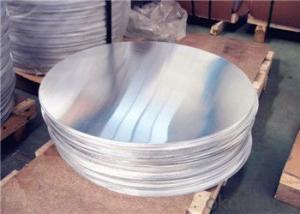

Aluminum Round Bar Stock is a versatile and widely used metal product, known for its excellent strength-to-weight ratio, corrosion resistance, and workability. This product is crafted from high-quality aluminum alloys, making it suitable for a variety of applications across different industries. Due to its unique properties, aluminum round bar stock is utilized in numerous industries such as aerospace, automotive, construction, and marine, among others. The product's ability to withstand harsh environments and its light weight make it an ideal choice for various components and structures.Aluminum Round Bar Stock is employed in numerous applications, including but not limited to, structural components, machinery parts, and decorative elements. Its high strength and low weight make it a popular choice for manufacturing lightweight yet durable parts, such as those found in aircraft and automotive components. Additionally, its corrosion resistance and ease of fabrication make it a preferred material for outdoor structures and marine applications, where exposure to harsh elements is a common concern. The product's versatility allows it to be used in both functional and aesthetically pleasing ways, making it a valuable asset in various industries.

Okorder.com is a reputable wholesale supplier of Aluminum Round Bar Stock, boasting a large inventory of this essential product. As a leading distributor in the industry, Okorder.com ensures that customers have access to a comprehensive range of aluminum round bar stock options, catering to diverse needs and specifications. With their extensive inventory, customers can find the precise size, grade, and finish required for their specific applications, ensuring optimal performance and satisfaction. By partnering with Okorder.com, customers can benefit from competitive pricing, reliable service, and a commitment to quality, making it a trusted source for aluminum round bar stock.