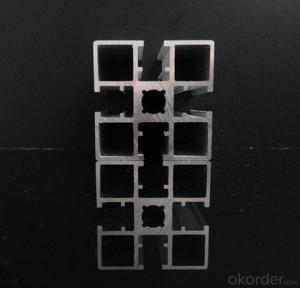

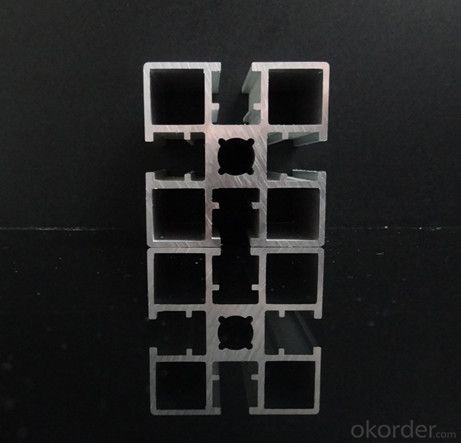

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 7005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Hello, I do not know if you have any requirements to the region, if not, you can consider the manufacturers here in Foshan?Industrial aluminum extrusion machine operation rules and precautions (looking for aluminum profiles manufacturers search: "Foshan bright silver custom")First from the process analysis:1. open aluminum extrusion machine, must ensure that equipment around and on the machine no debris, oil2. prepare the material according to the production request, and then pour into the tank according to the proportion3. check the power status and acknowledge the normal operation of the control cabinet

- Q: Can aluminum profiles be used for creating protective enclosures?

- Indeed, protective enclosures can be fashioned using aluminum profiles. Aluminum, being a lightweight, long-lasting, and corrosion-resistant substance, proves itself fitting for a plethora of purposes, including protective enclosures. By effortlessly fabricating and assembling aluminum profiles, one can generate tailored enclosures of diverse dimensions and forms. They grant exceptional structural integrity and endure even the harshest environmental circumstances. Furthermore, in the event that efficient heat dispersal is necessary, aluminum profiles present commendable thermal conductivity. All in all, the versatility, strength, and durability of aluminum profiles render them a favored choice for the creation of protective enclosures.

- Q: Can aluminum profiles be used in the production of signage?

- Yes, aluminum profiles can be used in the production of signage. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it suitable for outdoor and indoor signage applications. It can be easily cut, shaped, and assembled to create custom signage designs. Additionally, aluminum profiles can provide a sleek and modern aesthetic to signage projects.

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a specific project.

- <p>To calculate the amount of aluminum profiles needed for a project, first, determine the dimensions and design of the structure. Measure the length, width, and height of the required profiles. Consider the number of profiles needed for each section of the project. Multiply the length of each profile by the number of profiles required. Sum these totals for all sections to get the overall amount of aluminum needed. Factor in a margin for cutting and waste to ensure you have enough material. Consult with suppliers or use specialized software for more precise calculations, especially for complex projects.</p>

- Q: Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material that offers high strength-to-weight ratio, corrosion resistance, and versatility. These qualities make it suitable for various transportation applications such as aircraft, automobiles, trains, ships, and even bicycles. Aluminum profiles are commonly used in the construction of vehicle bodies, frames, panels, and other structural components, helping to reduce weight and enhance fuel efficiency.

- Q: Whether aluminum profile of glass curtain wall needs compulsory test?

- Quality inspection standard for glass curtain wall project required2.7 quality assurance materialsFor the inspection of 2.7.1 aluminum alloy sections, the following materials should be provided:Product certification of 1. profiles.Mechanical performance test report of 2. profiles, profile should be imported by the State commodity inspection department inspection certificate.

- Q: What are aluminum profiles used for?

- Aluminum profiles are commonly used in construction, manufacturing, and industrial applications. They are used for framing structures, such as doors, windows, and curtain walls, providing strength and durability while maintaining a lightweight design. Additionally, aluminum profiles are used in the production of machinery, electrical enclosures, automotive parts, and various consumer products, due to their corrosion resistance, heat conductivity, and versatility in shaping.

- Q: Are there any special considerations for installing aluminum profiles?

- Yes, there are a few special considerations for installing aluminum profiles. Firstly, it is important to ensure that the installation surface is clean and free from any debris or contaminants that could affect the adhesion or stability of the profiles. Secondly, proper measurement and alignment are crucial for a precise and secure installation. Additionally, it is advisable to use appropriate tools and techniques for cutting and shaping the profiles to avoid any damage or distortion. Finally, if the installation involves outdoor or high-moisture areas, it is recommended to use aluminum profiles that are specifically designed for such conditions to ensure longevity and durability.

- Q: This question seeks advice on making the aluminum profile production process eco-friendly.

- <p>To ensure an environmentally friendly production process for aluminum profiles, consider the following: Use recycled aluminum whenever possible to reduce the energy needed for production. Implement energy-efficient technologies and machinery in the production line. Minimize waste by optimizing production processes and recycling any aluminum scraps generated. Employ water-saving measures and treat any wastewater before discharge. Reduce emissions by using low-emission fuels and investing in pollution control equipment. Regularly monitor and assess the environmental impact of your operations and strive for continuous improvement.</p>

- Q: Can aluminum profiles be used for medical equipment or devices?

- Yes, aluminum profiles can be used for medical equipment or devices. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of various medical devices such as wheelchairs, surgical instruments, diagnostic equipment, and prosthetics. Its corrosion resistance, strength, and versatility make it suitable for a wide range of medical applications. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, making them a popular choice in the medical industry.

Send your message to us

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords