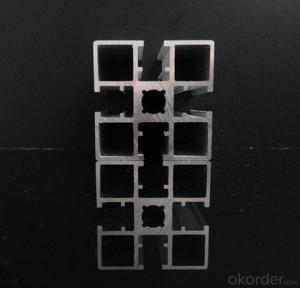

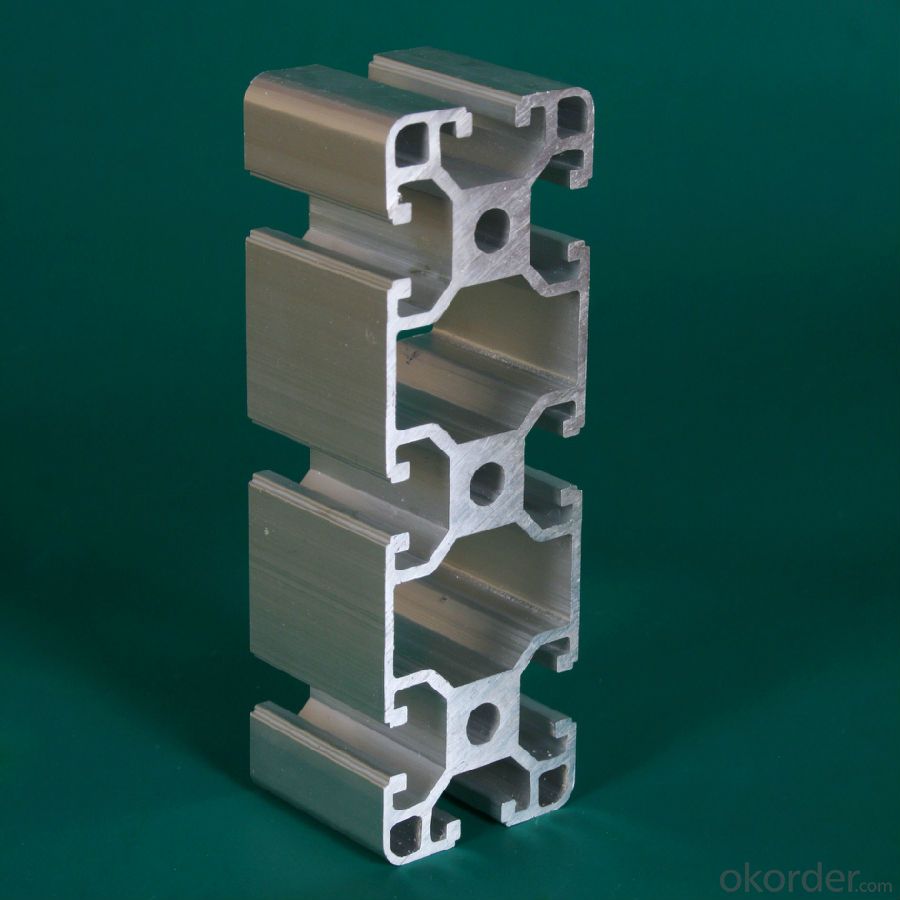

Customized Alloy 7075 Aluminum Extrusion Profiles for Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 7075 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Is it possible to utilize aluminum profiles in interior design projects?

- <p>Yes, aluminum profiles can be used for interior design. They are popular for their strength, durability, and modern aesthetic. Aluminum profiles are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications such as window frames, door frames, shelving systems, and decorative elements. They can be powder-coated or anodized to achieve different colors and finishes, allowing for a wide range of design flexibility.</p>

- Q: Can aluminum profiles be used in transportation and logistics applications?

- Yes, aluminum profiles are commonly used in transportation and logistics applications. Aluminum profiles are lightweight yet strong, making them an ideal choice for various components in the transportation and logistics industry. In the automotive sector, aluminum profiles are used in the manufacturing of car frames, chassis, and body panels. Their lightweight nature helps reduce the overall weight of the vehicle, resulting in improved fuel efficiency and lower emissions. Additionally, aluminum profiles offer excellent corrosion resistance, ensuring the longevity of the vehicle in harsh environmental conditions. In the aerospace industry, aluminum profiles are extensively used in the construction of aircraft structures, such as wings, fuselage, and landing gear. The high strength-to-weight ratio of aluminum profiles allows for increased payload capacity and fuel efficiency. Moreover, aluminum profiles can withstand extreme temperature variations and have good electrical conductivity, making them suitable for various aerospace applications. In the logistics sector, aluminum profiles are used for constructing cargo containers, pallets, and storage racks. The lightweight nature of aluminum profiles facilitates easy handling and transportation of goods. Additionally, aluminum profiles offer high resistance to rust and corrosion, ensuring the durability of logistics equipment even in humid or corrosive environments. Furthermore, aluminum profiles can be easily customized and fabricated to meet specific design requirements in transportation and logistics applications. They can be extruded into various shapes and sizes, allowing for versatility in design and functionality. Moreover, aluminum profiles can be joined using various methods like welding or fastening, providing flexibility in assembly and maintenance. In conclusion, aluminum profiles are indeed suitable for transportation and logistics applications due to their lightweight, strength, corrosion resistance, and versatility. They offer numerous benefits such as improved fuel efficiency, increased payload capacity, and durability in harsh environments. Thus, aluminum profiles are widely used in automotive, aerospace, and logistics industries for various components, contributing to the efficiency and reliability of transportation and logistics systems.

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: The user is inquiring about the efficiency of aluminum profile recycling in their region and seeks details on how it can be done.

- <p>Yes, aluminum profiles can be recycled efficiently in most regions due to their high value and the relatively low energy required for recycling. The process typically involves collection, sorting, melting, and recasting into new aluminum products. To recycle aluminum profiles in your region, you can check for local recycling centers or scrapyards that accept aluminum. Some municipalities also have curbside recycling programs that include aluminum. Ensure that the profiles are clean and free of non-aluminum components before recycling to maximize their value and efficiency in the recycling process.</p>

- Q: This question asks whether aluminum profiles can be joined using welding or bolting methods.

- <p>Yes, aluminum profiles can be both welded and bolted together. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity, but it is possible and results in a strong joint. Bolting is a common method for joining aluminum profiles, as it is quick, easy, and does not require melting the material. It is important to use appropriate hardware and techniques to ensure a secure and durable connection.</p>

- Q: What are the different powder coating options for aluminum profiles?

- There are several different powder coating options available for aluminum profiles, each offering unique advantages and characteristics. 1. Polyester powder coating: This is the most common and economical option for aluminum profiles. It provides excellent UV resistance and color retention, making it suitable for both indoor and outdoor applications. Polyester powder coatings are available in a wide range of colors and finishes, including matte, glossy, and textured. 2. Epoxy powder coating: Epoxy coatings offer excellent adhesion and corrosion resistance, making them suitable for demanding environments such as marine or industrial applications. They have good chemical resistance and are often used as a primer before applying a topcoat for added durability. 3. Polyurethane powder coating: Polyurethane coatings provide exceptional durability and resistance to abrasion, making them ideal for high-traffic areas or surfaces that are prone to wear and tear. They offer excellent color retention and gloss retention, ensuring a long-lasting finish. 4. Fluoropolymer powder coating: Fluoropolymer coatings, such as PVDF (polyvinylidene fluoride), are known for their outstanding resistance to chemicals, UV radiation, and weathering. They are highly durable and provide excellent color retention, making them suitable for architectural applications where long-term performance is essential. 5. Hybrid powder coating: Hybrid coatings are a combination of epoxy and polyester resins, offering a balance of excellent adhesion and color retention. They provide good weather resistance and are often used in general-purpose applications where cost-effectiveness is a priority. It's important to consider the specific requirements of your project when choosing a powder coating option for aluminum profiles. Factors such as intended use, environmental conditions, and desired aesthetics will help determine the most suitable option for achieving the desired performance and appearance.

- Q: Can aluminum profiles be used for security doors and windows?

- Yes, aluminum profiles can be used for security doors and windows. Aluminum is a strong and durable material that is resistant to corrosion, making it an ideal choice for security applications. Aluminum profiles can be designed and manufactured to meet specific security requirements, such as reinforced frames, multi-point locking systems, and impact-resistant glass. Additionally, aluminum profiles offer a sleek and modern aesthetic, allowing for the creation of stylish security doors and windows. Overall, aluminum profiles provide a reliable and secure solution for enhancing the safety and protection of both residential and commercial properties.

- Q: Are aluminum profiles suitable for conveyor systems?

- Conveyor systems can benefit from the suitability of aluminum profiles. Aluminum, which is used in various industries due to its advantages, is both lightweight and durable. To begin with, aluminum profiles possess a favorable strength-to-weight ratio, making them perfect for conveyor systems. They can support heavy loads while remaining lightweight, facilitating easy installation and allowing for design flexibility. This attribute is particularly advantageous in conveyor systems that prioritize efficiency and ease of movement. Secondly, aluminum profiles exhibit resistance to corrosion. Unlike other metals, aluminum does not rust. As a result, the conveyor system can enjoy longevity and reliability, which is especially crucial in industries dealing with moisture or harsh environments. Furthermore, aluminum profiles offer exceptional customization options. They can be easily machined and shaped to match the specific requirements and dimensions of the conveyor system. This capability enables the creation of unique and efficient designs that ensure optimal performance and functionality. In addition, aluminum profiles possess excellent thermal conductivity. They efficiently dissipate heat, preventing potential damage or overheating to the conveyor system. This feature proves particularly beneficial in industries involving high-temperature processes. Moreover, aluminum profiles prove to be cost-effective. Although the initial investment may be slightly higher compared to other materials, the long-term benefits outweigh the costs. Aluminum requires minimal maintenance, reducing downtime and associated expenses. In conclusion, aluminum profiles are indeed suitable for conveyor systems. Their lightweight nature, corrosion resistance, customization options, thermal conductivity, and cost-effectiveness make them an ideal choice for a wide range of conveyor applications.

- Q: How do aluminum profiles perform in blast-resistant structures?

- Aluminum profiles perform well in blast-resistant structures due to their high strength-to-weight ratio and excellent energy absorption capabilities. They can effectively dissipate and redirect the force of an explosion, minimizing damage and providing enhanced protection. Additionally, aluminum profiles offer corrosion resistance, durability, and ease of fabrication, making them a suitable choice for blast-resistant construction.

- Q: What are the different surface embossing options for aluminum profiles?

- Aluminum profiles offer a variety of surface embossing options, each with its own unique textures and patterns. Some commonly used options include: 1. Diamond pattern: This option creates a diamond-shaped pattern on the profile's surface, providing both visual appeal and improved grip. It is ideal for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. It is often used in applications where aesthetics play a crucial role, such as architectural facades or interior design elements. 3. Hammer tone pattern: This option gives the aluminum profile a hammered texture, providing a distinctive and rustic appearance. It is popular in decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and look of natural wood. It is commonly chosen for applications like window frames or doors when a traditional or natural appearance is desired. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the profile's surface. It is frequently used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's worth noting that these embossing options can be customized or combined to meet specific design requirements. Manufacturers may offer additional options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

Send your message to us

Customized Alloy 7075 Aluminum Extrusion Profiles for Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords