Alloy 6061 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

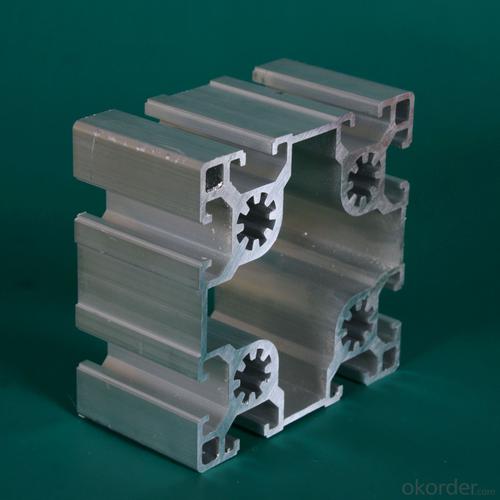

Product Name | Alloy 6061 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Are aluminum profiles suitable for curtain walls and facades?

- Curtain walls and facades benefit greatly from the use of aluminum profiles, given their lightweight, durable, and versatile nature. Firstly, these profiles exhibit exceptional strength and structural integrity, enabling them to withstand various weather conditions and forces such as wind loads and seismic activity. Consequently, they prove ideal for applications where structural stability is paramount. Moreover, aluminum boasts remarkable resistance to corrosion, making it an essential attribute for exterior applications. Its resistance to rust and deterioration when exposed to moisture and other environmental factors ensures the longevity and durability of curtain walls and facades. Furthermore, aluminum profiles offer remarkable design flexibility, as they can be easily extruded into different shapes and sizes. This versatility allows for the creation of visually appealing and unique curtain wall systems and facades. Additionally, aluminum's high strength-to-weight ratio facilitates the construction of expansive glazed areas while minimizing the overall weight of the structure. Installation and maintenance of aluminum profiles are also simple and straightforward. They can be prefabricated and assembled off-site, resulting in reduced on-site construction time and costs. Moreover, aluminum requires minimal maintenance, typically only necessitating occasional cleaning to preserve its appearance and functionality. Furthermore, aluminum is a sustainable material, fully recyclable and capable of being reused and repurposed at the end of its lifecycle. This characteristic significantly reduces waste and environmental impact, aligning with the increasing demand for eco-friendly and sustainable building practices. In conclusion, the numerous advantages of aluminum profiles, including their strength, durability, corrosion resistance, design flexibility, ease of installation and maintenance, as well as their sustainability, make them highly suitable for curtain walls and facades. Architects, engineers, and building owners often choose aluminum profiles for these applications due to the benefits they offer.

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: How do aluminum profiles provide structural stability?

- Structural stability is achieved through the inherent properties and design characteristics of aluminum profiles. The lightweight and strong nature of aluminum makes it an ideal material for constructing different structures. Its high strength-to-weight ratio allows it to support heavy loads while keeping the overall weight of the structure to a minimum. Moreover, aluminum profiles can be designed in various shapes and cross-sections, enabling optimal load distribution and maintaining structural integrity. These profiles can be extruded into shapes like I-beams, T-sections, or rectangular profiles, enhancing the strength and rigidity of the structure. Additionally, aluminum exhibits excellent resistance to corrosion, ensuring the durability and structural soundness of the profiles even in harsh environments. This corrosion resistance eliminates the need for frequent maintenance and extends the lifespan of the structure. Furthermore, aluminum profiles are easily fabricated and assembled, making construction efficient and cost-effective. They can be cut, drilled, welded, or fastened together to create complex structures with precise dimensions. This flexibility in fabrication and assembly allows the profiles to be customized to meet specific design requirements and provide optimal structural stability. In conclusion, aluminum profiles offer structural stability due to their lightweight strength, versatile design options, corrosion resistance, and ease of fabrication and assembly. These properties make aluminum profiles a preferred choice in various industries, including construction, transportation, aerospace, and others.

- Q: Are aluminum profiles suitable for protective enclosures?

- Yes, aluminum profiles are suitable for protective enclosures. Aluminum is a lightweight yet strong and durable material, making it ideal for constructing protective enclosures. It offers excellent resistance to corrosion, UV rays, and extreme weather conditions, making it suitable for both indoor and outdoor applications. Aluminum profiles can be easily customized and fabricated to meet specific enclosure requirements, such as size, shape, and design. Additionally, aluminum is a non-magnetic material, which can be advantageous in certain applications where magnetic interference needs to be minimized. Overall, aluminum profiles provide a reliable and cost-effective solution for building protective enclosures in various industries, including electronics, telecommunications, automotive, and more.

- Q: Are aluminum profiles suitable for use in roofing systems in areas with high wind conditions?

- <p>Yes, aluminum profiles can be used for roofing systems in windy regions. Aluminum is a lightweight and durable material that can withstand high winds. It is often used in the construction of roofing systems because of its strength and resistance to corrosion. Additionally, aluminum profiles can be designed to meet specific wind load requirements, making them suitable for areas prone to strong winds. However, the design and installation of the roofing system must be done correctly to ensure it can handle the wind forces.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials concerning cost and availability.

- <p>Aluminum profiles are generally cost-effective and widely available compared to other materials. They are less expensive than materials like stainless steel and titanium, making them a popular choice for various applications. Aluminum is also readily available in the market due to its high demand in industries such as construction, automotive, and aerospace. Additionally, aluminum has a lower density, which means it's lighter and easier to transport and handle, further reducing costs. However, the cost and availability can vary depending on market conditions, geographical location, and specific alloy types.</p>

- Q: What are the different surface polishing options for aluminum profiles?

- There are several surface polishing options for aluminum profiles, including mechanical polishing, chemical polishing, electro-polishing, and anodizing. Mechanical polishing involves the use of abrasive materials to remove imperfections and create a smooth surface. Chemical polishing uses chemical solutions to dissolve a thin layer of aluminum and produce a polished finish. Electro-polishing uses an electric current to remove surface imperfections and create a shiny surface. Anodizing is a process in which a protective oxide layer is formed on the surface of the aluminum, providing both a polished appearance and enhanced corrosion resistance.

- Q: in addition to the groove width is not the same as other well differentiated? Is there any difference in wall thickness?

- There must be a difference. There is a distinction between rice weight and wall thickness. For example, Jing Teng Aluminum CompanyJT-8-5050W meters weight is 3.25KG,,JT-10-5050 meters weight is 2.95KG. Specific parameters, you can go to consult the next business

- Q: This question asks for a list of various roofing systems that incorporate the use of aluminum profiles.

- <p>Aluminum profiles are used in several types of roofing systems for their durability, lightweight, and corrosion resistance. Some common types include: 1. Standing Seam Roofing: Known for its sleek, clean appearance and watertight properties. 2. Aluminum Shingle Roofing: Mimics the look of traditional shingles but with the benefits of aluminum. 3. Metal Tile Roofing: Offers the aesthetic of clay or slate tiles with the strength of aluminum. 4. Aluminum Panel Roofing: Consists of large panels that cover a broad area quickly and efficiently. 5. Aluminum Shake Roofing: Provides a rustic look similar to wooden shakes but with the longevity of aluminum. Each system has its own advantages and is chosen based on factors like design, cost, and environmental conditions.</p>

- Q: Can aluminum profiles be used in electrical enclosure manufacturing?

- Yes, aluminum profiles can be used in electrical enclosure manufacturing. Aluminum is a versatile and lightweight material that offers excellent electrical conductivity, heat dissipation, and corrosion resistance. It can be easily shaped into different profiles to suit specific enclosure designs and can provide adequate protection for electrical components.

Send your message to us

Alloy 6061 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords