Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile of Well Sturctured and Good Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Well Sturctured and Good Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

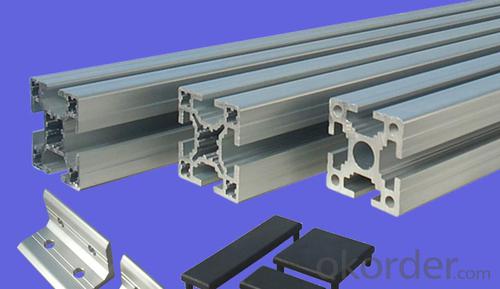

3.Aluminium Profile of Well Sturctured and Good Quality Images:

4.Aluminium Profile of Well Sturctured and Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: Can aluminum profiles be used for framing mirrors?

- Yes, aluminum profiles can be used for framing mirrors. Aluminum is a lightweight and durable material that can provide a sleek and modern look to mirror frames. It is also resistant to corrosion, making it suitable for use in bathrooms or other areas with high humidity. Additionally, aluminum profiles can be easily customized and come in various finishes, allowing for flexibility in design.

- Q: Can aluminum profiles be extruded into hollow profiles?

- Yes, like aluminum tubes. This is hollow

- Q: How much is aluminum freight per kilometer per ton?

- The most accurate and effective way of Logistics: find a phone call to ask ah, less than 1 tons and tons of vehicle and hair are not the same, where to go is not the same, some small place to transfer is much more expensive, General Logistics 1 tons in about 500

- Q: What are the differences between horizontal and vertical aluminum profiles?

- Vertical jet powder will be better than horizontal, horizontal spray is not good, there will be a zebra crossing

- Q: Is there any health risk linked to the use of aluminum profiles in construction?

- <p>There are minimal health risks associated with using aluminum profiles in construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be exposure to dust or fumes which could be harmful if inhaled. Additionally, aluminum dust can cause skin irritation. It's important to handle aluminum profiles with care and use appropriate safety measures, such as wearing masks and gloves, to minimize any potential health risks.</p>

- Q: This question asks about the various types of aluminum profiles that are utilized in interior design applications.

- <p>Aluminum profiles are widely used in interior design for their strength, durability, and aesthetic appeal. Common types include: 1. Linear Profiles for creating sleek lines in furniture and architectural elements; 2. Structural Profiles for load-bearing structures like beams and columns; 3. Decorative Profiles for ornamental purposes, such as moldings and trims; 4. Frame Profiles for framing pictures, mirrors, and other wall-mounted items; 5. Slatwall Profiles for versatile display systems in retail spaces; 6. Handrail Profiles for stairways and balconies, ensuring safety and style; 7. Window and Door Profiles for modern, lightweight, and energy-efficient applications. Each type is chosen based on the specific design requirements and functional needs of the space.</p>

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a commonly used material in cleanroom construction due to its non-porous and non-shedding properties. It is easy to clean, resistant to corrosion, and can withstand rigorous cleaning processes without compromising its structural integrity. Additionally, aluminum profiles can be easily customized and assembled to meet the specific needs and requirements of a cleanroom environment.

- Q: This question asks for a list of various types of fasteners that can be used with aluminum profiles specifically designed for outdoor applications.

- <p>Aluminum profiles for outdoor applications commonly use several types of fasteners to ensure secure and durable connections. These include: 1. T-nuts and T-bolts, which provide a strong and hidden connection within the profile. 2. Clamping blocks or plates, which are used for external fastening and can be easily adjusted. 3. Corner brackets, which are used to connect profiles at right angles. 4. Hinges, which allow for pivoting movements in doors or gates. 5. Screws and bolts, which are versatile and can be used in various configurations. 6. Adhesives, which can provide a strong bond in certain applications where mechanical fasteners are not suitable. 7. Rivets, which offer a permanent connection once installed. Each type of fastener is chosen based on the specific requirements of the outdoor structure, such as load-bearing needs, resistance to weather, and aesthetic considerations.</p>

Send your message to us

Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords