Profile Extrusion

Profile Extrusion Related Searches

Plastic Extrusion Profiles Extruded Plastic Profiles Aluminium Extrusion Multi Plastics Extrusion Aluminum Extrusion Framing Aluminum Extrusions Aluminum Extrusion Shapes Aluminum Extrusion Plate Misumi Extrusion Bosch Aluminum Extrusion Extruded Polystyrene Foam Plastic Extrusion Melbourne Extruded Polystyrene Foam Board Extruded Aluminum Track Extruded Polystyrene Xps American Thermoplastic Extrusion Company Frp Pultrusion Extruded Polystyrene Thermal Conductivity Aluminum Extruded Tubing Precision Slitting Ducting Exhaust Extruded Aluminum Beams Extruded Aluminum Rail Standard Wood Trim Profiles Automotive Weatherstripping Profiles Perforated Particle Board Direct Roving For Pultrusion Electronic Encapsulation Grinding Abrasive Cutting Excess Electronic ComponentsProfile Extrusion Supplier & Manufacturer from China

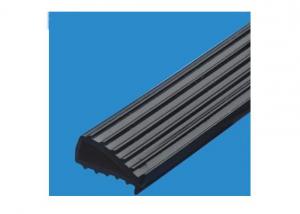

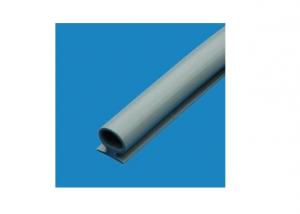

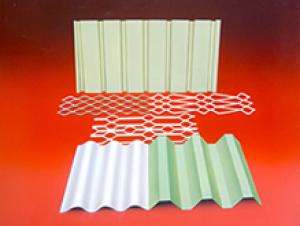

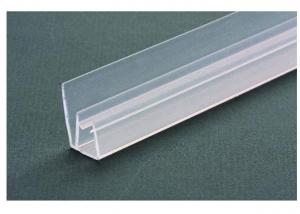

Profile Extrusion is a manufacturing process that produces various long, continuous parts with a uniform cross-sectional profile. These extruded profiles are widely used in numerous industries, such as construction, automotive, aerospace, and consumer goods, due to their strength, durability, and cost-effectiveness. The versatility of profile extrusion allows for the creation of complex shapes and designs that can be tailored to specific applications and requirements.Profile extrusion products are commonly used in applications where structural integrity and lightweight materials are essential. For instance, in the construction industry, extruded aluminum profiles are utilized for window frames, door frames, and curtain walls. In the automotive sector, they are employed for bumpers, hoods, and other vehicle components. Additionally, profile extrusion is employed in the manufacturing of various consumer goods, such as furniture, appliances, and electronics housings. The usage scenarios for these extruded profiles are vast, making them an indispensable component in many industries.

Okorder.com is a reputable wholesale supplier of profile extrusion products, boasting a large inventory of high-quality extruded profiles. They offer a comprehensive range of materials, including aluminum, steel, and plastic, catering to the diverse needs of their customers. By partnering with Okorder.com, businesses can access a vast selection of profile extrusion products at competitive prices, ensuring that they can meet the demands of their projects and stay ahead in their respective industries.

Hot Products