Plastic Extrusion Melbourne

Plastic Extrusion Melbourne Related Searches

Multi Plastics Extrusion Plastic Extrusion Profiles Aluminium Extrusion Extruded Plastic Profiles Profile Extrusion Methylcellulose Australia Aluminum Extrusions Aluminum Extrusion Plate Extruded Polystyrene Xps American Thermoplastic Extrusion Company Misumi Extrusion Trim Plastics Aluminum Extrusion Framing Aluminum Extrusion Shapes Bosch Aluminum Extrusion Plastic Greenhouse Uk Plastic Netting Uk Plastic Injection Molds Aluminum Extruded Tubing Plastic Tube Singapore Plastic Tubing L Shaped Plastic Molding Plastic Crusher Garden Plastic Sheeting Rectangular Plastic Tubing Plastic Tube Slide Extruded Rubber Seals Pond Liners Brisbane Green Plastic Netting Plastic Crusher MachinePlastic Extrusion Melbourne Supplier & Manufacturer from China

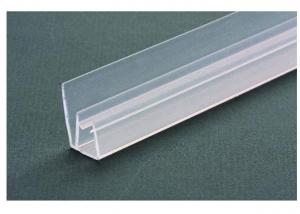

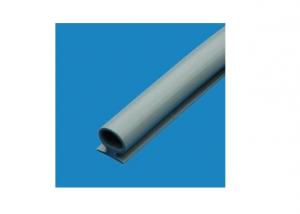

Plastic Extrusion Melbourne offers a wide range of high-quality plastic extrusion products, catering to various industries and applications. These products are designed and manufactured to meet the specific needs of customers, ensuring durability and performance. The extrusion process allows for the creation of a variety of shapes and sizes, making it a versatile choice for numerous applications.Plastic extrusion products from Melbourne are widely used in construction, automotive, packaging, and electrical industries, among others. They provide reliable solutions for insulation, sealing, and structural support, making them indispensable in various usage scenarios. These products are known for their resistance to corrosion, weathering, and wear, ensuring long-lasting performance and value.

Okorder.com is a leading wholesale supplier of Plastic Extrusion Melbourne, boasting a large inventory to cater to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products are manufactured to the highest standards and are readily available for purchase. This makes Okorder.com the go-to destination for those seeking reliable and high-quality plastic extrusion products from Melbourne.

Hot Products