CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

worked in this field for more than 5 years

Life span more than 15 years

world first class spare parts,lowest failure rate

Fully Automatic Blow-molding Machine

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

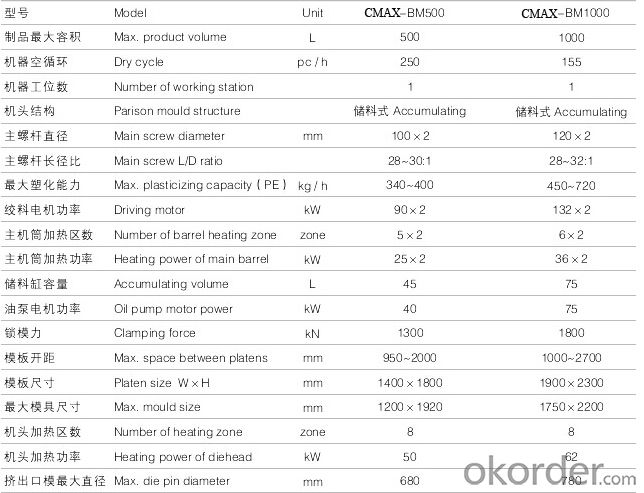

D.Technical Parameter:

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

D.Technical Parameter:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q: What is the reason for the fuel injection of the turbine vacuum pump?

- 2, the vacuum tank discharge oil blocked or poor drainage, resulting in the vacuum tank oil level is too high. 3, oil filter just cast, internal accumulation of gas is too much, generally over a period of time (about 10 minutes later) just fine, so just put into the small oil pump outlet valve and vacuum pump inlet valve, and then gradually opened.

- Q: I use the 300 frame oil filter to filter the oil. What size filter paper should I use?

- Compression method manual screw compressionThe ambient temperature of -25 to 70 DEG CThe medium temperature -25 to 90 DEG CPower 380V/50HZ (three-phase four wire) or according to customer needsThe noise is less than 70dBMotor power (KW) 5.5 KWThe inlet and outlet diameter is 60 mmEquipment weight 600KgOutline size 1600mm * 600mm * 1100mmThe continuous working time is more than 150hMTBF > 5000h

- Q: What's the name of the glass tubing that filters the oil-water separation?

- Liquid level meter, you can clearly see the oil and water stratification.

- Q: What is the working principle of the oil filter?

- Working principle of oil filterThere is a rotor with double jet nozzle in its interior, only produced by oil pressure to provide the driving force. After the device is opened, the oil in the tank is sent to the rotor through the pump. When the oil is filled with the rotor, the nozzle is ejected along the lower part of the turntable

- Q: Excuse me, what's the reason why the oil is not clear and cloudy after being filtered by the centrifugal oil filter?

- The centrifugal oil filter can be used in addition to impurities, but the water removal effect is somewhat worse than that of the vacuum oil filter. The turbidity may be emulsified by the oil inlet

- Q: My vacuum oil filter doesn't filter. Consult an expert

- As a kind of non-standard machinery and equipment, non professional personnel is best not to self disassembly and installation, troubleshooting appear professional needs, so suggest you pick up the oil filter company purchasing telephone calls, seek professional customer service service

- Q: Why does the oil filter run out of vacuum? How can we solve it?

- The oil filter in the operation process, occurring commonly used vacuum pump oil phenomenon, this is because the oil in the water too much, vacuum pumping, lead to a bubble too much, and some manufacturers of vacuum oil filter machine is not installed on the oil filter with automatic defoaming device, resulting in excessive foaming due to vacuum separator. The oil ejected from the exhaust of the vacuum pump in the mouth

- Q: What's the difference between an oil filter and an oil filter?

- According to your actual situation, there are first class filtration, three stage filtration and so on. Also, the size of the flow is different, the price is not the same yo. General small oil filter, thousands of dollars

- Q: Comparison of performances of several oil filters

- Features: good effect of oil - containing water on the separation effect of the separation of impurities; the oil is poor; it needs to be equipped with precision filter to filter out impurities; the installation and maintenance is troublesome,.4 ionization type oil filter is using the electric field intensity of water droplets, to weaken the strength of interfacial film. The water droplets collision coalesce into large particles, sedimentation and separation. Features: good - containing water on the separation of oil - water separation effect; the oil rate is low when the effect is poor; the demulsifying ability is not very strong,.5 coalescence type oil filter is based on the latest oil coalescence and separation principle as the basis liquid filtration and dewatering equipment. It has the features: high precision filtration, high efficient dewatering, good filtering effect; the demulsifying ability is very strong; the impurity removal effect is very good, and is suitable for high oil content in the purification of large and small flow system; the flexible movement, operation Quick and easy (one button start), free of maintenance

- Q: What is the influence of the vacuum degree of vacuum oil filter?

- Influence of vacuum degree of vacuum oil filter:1, if the high vacuum may occur after vacuum through the high boiling point, oil and water is close to that of a lot of oil with water to evaporate (which is why the vacuum tank has a condenser, it is mainly used for oil return and automatic drainage)

Send your message to us

CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords