Automatically Winder PE Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

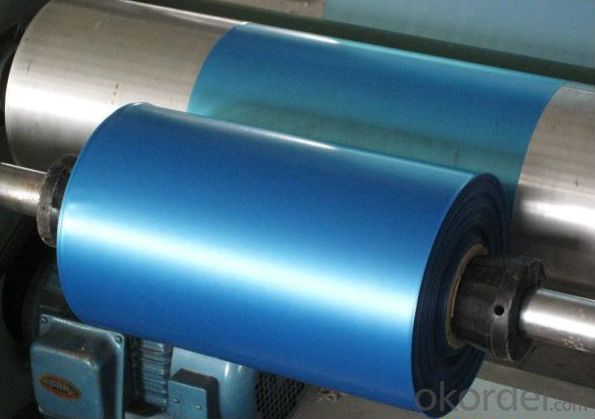

Automatically Winder PE Blown Film

1.Specifications

With Rotating Die Head

Save Labor

Little Waste

2.Features(with touch screen)

Full Automatically winder LDPE/HDPE film blowing machine/blown film machine

The machine is employed to produce plastic film made of low density polyethylene (LDPE), high density polyethylene (HDPE), linear low density polyethylene (LLDPE) and metallocene linear low density polyethylene (mLLDPE). Its products including shopping bags, T-shirt bags etc.

3.Main Techinical Parameters

MODEL NO. | SJ45-FMS650PG | SJ50-FMS850PG | SJ55-FMS1100PG | SJ65-FMS1300PG | |

LAYER NUMBER | 1 | ||||

MAX.FILM WIDTH | LD mm | 550 | 800 | 1050 | 1250 |

HD mm | 500 | 750 | 1000 | 1200 | |

FILM THICKNESS | LD mm | 0.015~0.10 | 0.020~0.15 | 0.020~0.18 | |

HD mm | 0.006~0.07 | 0.006~0.10 | 0.015~0.10 | 0.015~0.12 | |

OUTPUT | LD Kg/h | 40 | 55 | 70 | 100 |

HD Kg/h | 35 | 50 | 60 | 80 | |

RAW MATERIAL | HDPE,LDPE,LLDPE | ||||

EXTRUDER | |||||

SCREW DIAMETER | mm | Φ45 | Φ50 | Φ55 | Φ65 |

SCREW L/D | 28:1 | 28:1 | 30:1 | 25:1 | |

HEATER CAPACITY | kw | 8.9 | 10.7 | 10.7 | 13.2 |

DRIVING MOTOR | kw | 11 | 15 | 18.5 | 22 |

DIE:( Rotating die is optional) | |||||

DIE DIAMETER( LD&HD FREE CHOICE) | mm | LDPE Φ 150 | LDPE Φ 200 | LDPEΦ250 | LDPEΦ300 |

HDPEΦ50Φ70 | HDPEΦ60Φ80 | HDPEΦ60Φ90 | HDPEΦ80Φ110 | ||

HEATER CAPACITY | kw | LDPE 4.0 | LDPE 4.8 | LDPE6.15 | LDPE6.7 |

HDPE: 3.45 | HDPE: 3.45 | HDPE: 3.45 | HDPE: 6.1 | ||

COOLING AIR BLOWER | kw | 1.5 | 2.2 | 3 | |

HAUL-OFF: | |||||

DRIVING MOTOR | kw | 0.75 | 1.5 | ||

TAKE-UP SPEED | m/min | 10~70 | |||

WINDER DRIVE MOTOR | kw | 4 | 4.5 | ||

TEMPERATURE CONTROL | point | 5 | 6 | ||

WHOLE POWER WITH TOTAL MACHINE | kw | ~30 | ~36.5 | ~43 | ~52 |

SHAPE SIZE | m | 5.5 X 2.8 X 4.0 | 6.2 X 3.0 X 4.0 | 6.5 X 3.3 X 4.5 | 7.3 X 3.5 X 5.0 |

WEIGHT | t | 3 | 3.5 | 4 | 4.5 |

- Q: Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- Characteristic:1, super demulsification dehydration and degassing system, with large volume, enhanced three-dimensional flash tower and thin film evaporation technology and a large area of multi-level oil water gas separation technology, can fast remove the oil in the water, gas and light hydrocarbon.2, the use of high quality filter original and sealing materials, corrosion resistance, high temperature resistance, good mechanical strength, to meet the high viscosity of the filter oil needs higher temperature requirements, expanding the range of its purification of oil.3 、 precise multi-stage filtration system can effectively remove mechanical impurities in oil.4 、 advanced pressure protection device, liquid level control system, to avoid the misoperation of the equipment.5 、 perfect automatic and manual electric heating temperature control device, automatic separation cooling device, simple operation, safe and reliable.6, the machine can also be used to meter and timers, users can carry out automatic measurement of fuel quantity and working time.

- Q: Under what conditions does the air pressure oil filter fail to clean oil?

- Oil is too dirty or used in an unsuitable oil filter. There will be filters that are not clean

- Q: What is the trouble with the vacuum pump used in the oil filter? How can it be removed so that the oil filter works properly?

- The vacuum pumps used in oil filters usually do this:1. the exhaust of the vacuum pump is smoke;2. vacuum pumps, oil spills, oil spills;3. vacuum pump noise exceeds standard;4. vacuum decrease;5. vacuum pump, hot and so on;

- Q: Classification of oil filters According to the principle of the oil filter

- Three, reducing oil color, regeneration of oil filter. Such as vibration, slag discharge, decolorization, oil filter, automatic slag filter and so on.Four, including the above functions, filtered products by the national new oil standard (GB) qualified oil filter. For example, ZTS integrated purifier.Scope of applicationMainly applicable to mines, metallurgy, petroleum, rail, machinery, chemicals, textiles, cement, power plants, meters and other departments. The purification and regeneration of various industrial lubricating oils play a great role in the deterioration of pollution, prolong the overhaul cycle and service life of the equipment, and reduce production costs. It can effectively remove pollutants in oil, such as water, water soluble acid, alkali, mechanical impurities, etc., so as to improve the kinematic viscosity, flash point and emulsifying property of oil products. To quickly restore the oil to the required performance, close to or meet the corresponding national standards for new oil.

- Q: What happens when the oil heater is fired and the heater is tripped?

- Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

- Q: Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The accuracy of the filter is improved to a certain extent, and the new type of centrifuge has better rotation mode and transmission speed and higher centrifugal rate, so the filtering effect is also improved, and the filtering effect is improved in general.

- Q: Operation description of turbine oil vacuum oil filter?

- Water causes deterioration of oil quality. To slow down the oil quality, say to get rid of the water in the oil. The oil filter that you put together has not been used or seen, and I don't know its advantages and disadvantages, but I think it is a water filter that can remove water. Hope to be of help to you

- Q: I opened a small youfang! The oil used in centrifugal oil filters is always mixed

- [2] if the centrifugal oil filter does not have quality problems, you may have more water, water and oil emulsion or other reaction in the air, microbes and other external conditions, then the centrifugal oil filter incapable of action.[3] if your oil if it is used, which must produce colored material in high temperature process, and the centrifugal oil filter is not decoloring, so colored material will make edible oil looks cloudy.

- Q: Pressure filter and vacuum oil filter how to choose, prompt only know productivity Q

- The principle of electrostatic oil filter on the basis of attraction, using the Z potential of oil and water, colloid impurities, mechanical impurities and other impurities particles are different, when the impurity particles with the oil flow to the high pressure electrode plate, which quickly swim towards the opposite electrode direction, and is attached to the filter dirt between the upper electrode plate. At the same time, under the influence of static electricity, the impurity particles attached to the dust filter can also attract other impurity particles like the iron filings in the magnetic field. The separation principle has nothing to do with the size of the pollutant, but is related to the Z potential of the separated object.

- Q: The same function, one is installed in a part of a system, and the oil filter can move, do not need other devices can be completed independently

- From the above analysis, we can know that the dehydration efficiency of vacuum oil filter is at the moderate position in the three mainstream dehydration oil filters. The dewatering efficiency is the fastest ordinary coalescence oil filter, oil filter coalescence but high cost, the price is expensive, and cannot handle trace water and emulsion, behind the emergence and coalescence of the vacuum oil filter is the coalescence and vacuum technology, the coalescence vacuum has the ability of rapid dehydration and demulsification. Filtration, trace water, but the price is much higher than the vacuum oil filter, so many users will choose the vacuum oil filter, while the vacuum oil filter dewatering efficiency than the coalescence of oil filter, but the vacuum oil filter has the dehydration ability of all, but the actual dewatering efficiency is not slow, the price of the coalescence of oil filter much cheaper than the coalescence of oil filter or vacuum, the price is high. As for the centrifugal oil filter, which uses centrifugal dehydration, washing machine principle and shedding water, although the beginning of filtering a large amount of water quickly, but the centrifugal oil filter can not be broken and emulsification, dehydration ability is very limited, now a lot of industrial oil and water requirements are relatively high, centrifugal oil filter cannot to achieve the filtering requirements.

1. Manufacturer Overview

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatically Winder PE Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords