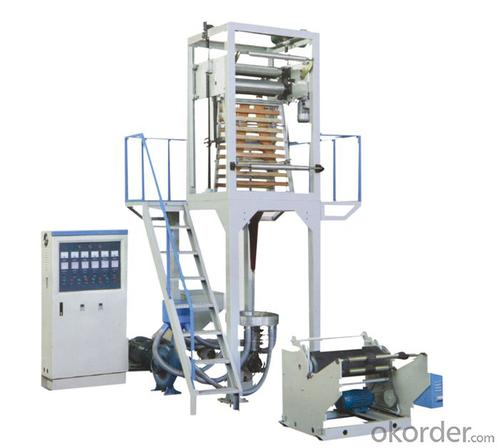

Plastic PE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

It is suitable for blowing the plastic film as high density polyethylene

(HDPE),low density polyethylene(LDPE) and linear low density

polyethylene(LLDPE),which is widely used for packing foodstuff,

garment,textile,daily-use articles and industrial products etc.It can

produce pearl film and degradation film via making up a prescription.

Characteristics:

1.The screw stem and cylinder are made of 38CRMOALA highquality alloy steel affer fine finishing and nitrided treatment,whichhas high hardness,strong resistance to corrosion,durable service.

2.The die head is plated with hard chrome,of screw mandrel

type structure with even and smooth discharging,the blown plastic

film has fine finishing

3.The blower is of labyrinth structure with even air output.

4.The winding unit adopts friction pressure rewinding or center

rewinding, which is driven by torque motor,with even and easy roll

changing.

Main Technical Parameter

MODEL | 45 | 50 | 55 | |||

SUITABLE MATERIAL | HDPE ,LDPE, LLDPE | |||||

FILM WIDTH (mm) | 800-1300 | 800-1500 | 1200-2000 | |||

FILM THICKNESS(HD) mm | 0.028-0.18 | 0.028-0.18 | 0.028-0.18 | |||

MAX EXTRUSION OUTPUT | 80-130kg/hr | 120-190kg/hr | 150-260kg/hr | |||

EXTRUDER | ||||||

SCREWDIAMETER (mm) | 45/50/45 | 50/55/50 | 55/65/55 | |||

SCREW L/D LENGTH | 28:1 | |||||

SCREW AND CYLINDER MATERIAL | SACM-645/38 CRMOALA | |||||

CYLINDER COOLING | 370W×2 /3 | 370W×2 /3 | 550W×2/3 | |||

TEMPERATURE CONTROL | 3X3 | 3X3 | 3X3 | |||

Average power-consume | 58kw | 70kw | 90kw | |||

MAIN MOTOR(KW) | 15/18.5/15 | 18.5/22/18.5 | 22/37/22KW | |||

TYPE OF DIE | ||||||

DIE SIZE (mm) | 200/250 | 250/300 | 350/400 | |||

Temperature control | 4 | |||||

AIR RING | 1 | |||||

Air blower | 5.5kw | 7.5kw | 11kw | |||

TAKE UPUNIT | ||||||

ROLLER WIDTH(mm) | 165×1400 | 165×1600 | 190×2100 | |||

TAKE-UP SPEED | 5-60m/min | 5-60m/min | 5-60m/min | |||

Take-up motor | 1.5KW | 1.5KW | 2.2KW | |||

WINDING UNIT | ||||||

Type | Surface friction type | |||||

Winding motor | 1.5kw | 1.5kw | 2.2kw | |||

Winding speed | 5-60m/min | 5-60m/min | 5-60m/min | |||

OVERALL DIMENSION(LXWXH) | 7.5x5.5x7m | 8.2X5.8x7m | 9X6.4X8.2 m | |||

Chnical Parameter:

MODEL | CW-3HL45 | CW-3HL50 | CW-3HL55 | |||

SUITABLE MATERIAL | HDPE ,LDPE, LLDPE | |||||

FILM WIDTH (mm) | 800-1300 | 800-1500 | 1200-2000 | |||

FILM THICKNESS(HD) mm | 0.028-0.18 | 0.028-0.18 | 0.028-0.18 | |||

MAX EXTRUSION OUTPUT | 80-130kg/hr | 120-190kg/hr | 150-260kg/hr | |||

EXTRUDER | ||||||

SCREWDIAMETER (mm) | 45/50/45 | 50/55/50 | 55/65/55 | |||

SCREW L/D LENGTH | 28:1 | |||||

SCREW AND CYLINDER MATERIAL | SACM-645/38 CRMOALA | |||||

CYLINDER COOLING | 370W×2 /3 | 370W×2 /3 | 550W×2/3 | |||

TEMPERATURE CONTROL | 3X3 | 3X3 | 3X3 | |||

Average power-consume | 58kw | 70kw | 90kw | |||

MAIN MOTOR(KW) | 15/18.5/15 | 18.5/22/18.5 | 22/37/22KW | |||

TYPE OF DIE | ||||||

DIE SIZE (mm) | 200/250 | 250/300 | 350/400 | |||

Temperature control | 4 | |||||

AIR RING | 1 | |||||

Air blower | 5.5kw | 7.5kw | 11kw | |||

TAKE UPUNIT | ||||||

ROLLER WIDTH(mm) | 165×1400 | 165×1600 | 190×2100 | |||

TAKE-UP SPEED | 5-60m/min | 5-60m/min | 5-60m/min | |||

Take-up motor | 1.5KW | 1.5KW | 2.2KW | |||

WINDING UNIT | ||||||

Type | Surface friction type | |||||

Winding motor | 1.5kw | 1.5kw | 2.2kw | |||

Winding speed | 5-60m/min | 5-60m/min | 5-60m/min | |||

OVERALL DIMENSION(LXWXH) | 7.5x5.5x7m | 8.2X5.8x7m | 9X6.4X8.2 m | |||

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- In the filter to filter out large particles of impurities in oil, but can not filter out the compound emulsion regeneration and oxide molecular structure, often need to pay attention to clean the filter in the process of using, easily broken or blocked.

- Q: What is the effect of the oil filter on the filtration of fine particles?

- When the temperature occurs, the reactions will not react with the filtered liquid and will pollute the filtered liquid. As long as it is not the core technology of the company, the problem of oil treatment and filtration can be exchanged.

- Q: How to assemble and disassemble the vacuum pump for power generation oil filter?

- You'd better consult someone who sold you the oil filter, so they would have to come in and install it during the warranty period

- Q: How often do you change the oil filter when the turbine is in oil?

- Mainly depends on your good quality of oil to determine. Generally, when the small post of the filter net comes out, it proves that the filter paper should be changed.

- Q: Excuse me, what's the reason why the oil is not clear and cloudy after being filtered by the centrifugal oil filter?

- [2] in the presence of oil colored substances dissolved in oil, the centrifugal oil filter that can only choose incapable of action, decolorization, if industrial oil can adsorb colored substances through clay, activated carbon and other substances, or by chemical reaction, but the technology is complex.

- Q: Oil filter HNP021-380-50-K-Z what does that mean?

- The 021 is usually produced in the factory number or date inside the company; the 380 is that the oil filter of the power is 380V, that is to say the oil filter of the power supply is 380V; 50 generally refers to the size of the flow of 50 liters per minute per hour or 50KG; K generally refers to the oil filter, according to the meaning, should refer to the anti fuel, which means that the oil filter is to filter the anti fuel (of course, may also have a fast and efficient filter means), Z generally refers to the vacuum oil filter, filter water.

- Q: What happens when the oil heater is fired and the heater is tripped?

- An oil filter is a filter device for removing mechanical impurities, byproducts and moisture in impure oil by gravity, centrifugal, pressure, vacuum distillation, mass transfer and other techniques.

- Q: What kind of oil can the oil filter handle?

- Only 1, ordinary oil filter cleaning and removal of micro water, such as frame type oil filter, oil filter machine, portable portable oil filter, can handle the oil is usually low viscosity lubricating oil, hydraulic oil, this kind of equipment can also be used as fuel for oil.

- Q: Who knows what the vibration of the oil filter is?

- Generally, the vibration of oil filters is very harmful: vibration, noise, accelerated wear of bearings, shortening of mechanical life, and serious damage accidents.There may be four reasons:1, the anchor screws loose. Solution: just tighten it2, the uneven thickness of sludge. Solution: clean the residue

- Q: Oil filter is good with filter or filter paper? Which place is good? Which unit is good?

- Which unit is better, this is easier to handle, choose a larger unit, technically good communication, the general situation is no problem. Hope to help you, the tripod can filter oil, hope to adopt, thank you

1. Manufacturer Overview

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords