PE Blown Film Extrusion Machine/Plastic Blow Film Machine/PE Plastic Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Blown Film Extrusion Machine/Plastic Blow Film Machine/PE Plastic Film Blowing Machine

1.SJ-B series film blowing machine use HDPE/LDPE/LLDPE as materials, after being heated, extruded,drawn and winding, then to be plastic film.It is widely applied to producing the packing bags for foodstuff,clothing,rubbish bag and vest ones. Its extruder and cylinder are made of quality alloy steel that have been nitrizied and processed in a precision way.Hence it is sound in hardness,durable in corrosion resistance, the specially-designed screw is of sound quality in plasticizing,which helps increase the production capacity.

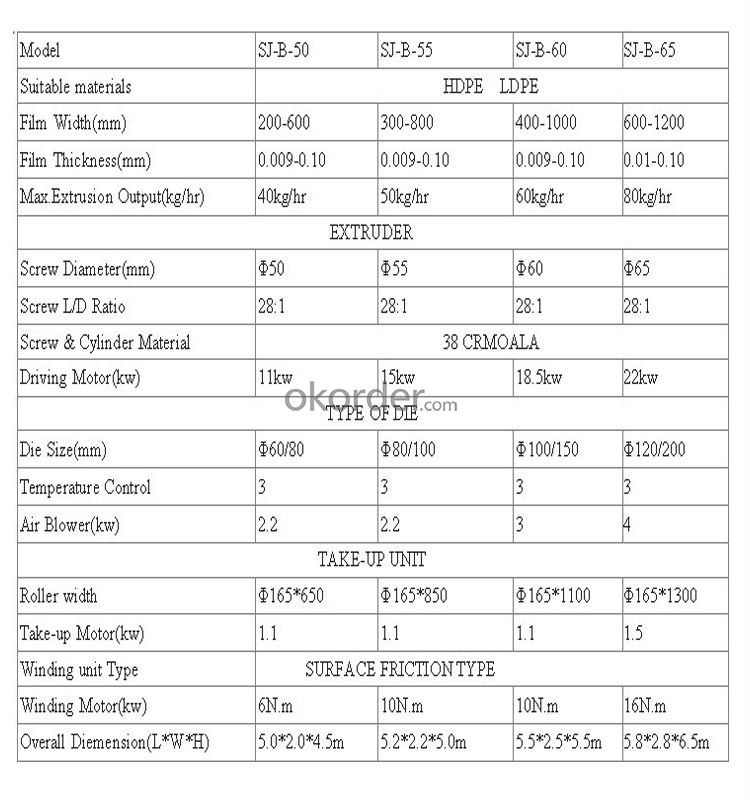

2.Main Technical Parameter

- Q: Under what conditions does the air pressure oil filter fail to clean oil?

- How do you say this? For example, the filter element, the filter element is used, right?

- Q: The oil filtered by a vacuum oil filter is then placed in a centrifugal oil filter and filtered without salt water

- When the centrifugal filter is started, the brine is added to the filter

- Q: The working principle of centrifugal oil filter

- . Model of the power transmission speed of the drum diameter of slag when producing kg/H YTLY50- a 1.5KW belt drive 1800 rpm with 430mm not cover 200 slag YTLY50- B (chrome plated) 1.5KW belt drive 1800 rpm with 430mm not cover 200 slag type YTLY60-a 2.2KW belt start 1800 rpm with 500mm cover slag 300 YTLY60- B (chrome plated) 2.2KW belt drive 1800 rpm with 500mm not cover 300 slag centrifugal oil filter operation steps: pressing hot crude oil into the hot brine 1-1.5% fully stirred, its purpose is the dephosphorization, because phosphorus will have osteoporosis and other diseases of the body, so the content index of first national oil standard is phosphorus limited, H2O. NaCl (saline) and phosphorus P produce chemical reaction to form heavy salt Na2PO5 (sodium phosphate) and H2 (hydrogen) with the increase of fine particles suction make brine Water content becomes heavy;

- Q: Hydraulic press to buy automatic integration of good or alone to buy the right?

- The oil press of an integral oil press is connected with an oil filter, and a vacuum oil filter is usually used. And the vacuum oil filter is relatively small, because the large oil filter can not hang.

- Q: The characteristics of plate and frame pressure oil filters? How often is the filter changed?

- The filter bed consists of multilayer filter plate and the filter frame, the filter media as paper or cloth lining the filter plate and the filter frame, with the pressure of the pressing device to filter plate and the filter frame to form a fixed filter chamber alone, tightly pressed between the filter plate and the filter frame of the paper or cloth filtration effect.

- Q: Advantages and disadvantages of pneumatic oil filter

- Vertical tank will be more than oil, you open the valve, drain oil ah. People say no bad oil, you believe ah?

- Q: Operation description of turbine oil vacuum oil filter?

- The vacuum oil filter has more water - retaining functions than the ordinary oil filter, because it has the function of water diversion, so as to use it. The role of turbine oil is to lubricate and cool the bearing of the turbine,

- Q: Fig. 1 electrical control diagram of lubricating oil vacuum oil filter lv_80

- Besides the general bought oil filter, as long as the regular manufacturers will have the instructions, the above detailed parameters of oil filter, and the electrical principle diagram and electrical control chart, do you buy the oil filter machine instructions are not even,. If so, either you choose to return it, or you call the person who sold it to you, and let them come home to deal with the problem, which is the minimum after-sales service.

- Q: Consult an expert, power plant turbine oil vacuum filter oil machine, why use ah, seems to be useful, poly junction separation, what are the advantages and disadvantages, thank you, urgent,

- The vacuum oil filter has more water - retaining functions than the ordinary oil filter, because it has the function of water diversion, so as to use it. The role of turbine oil is to lubricate and cool the bearing of the turbine. The oil is easy to enter steam because of its location and the position of the steam seal. Resulting in water, water, resulting in deterioration of oil quality. To slow down the oil quality, say to get rid of the water in the oil. The oil filter that you put together has not been used or seen, and I don't know its advantages and disadvantages, but I think it is a water filter that can remove water. Hope to be of help to you

- Q: Pressure filter and vacuum oil filter how to choose, prompt only know productivity Q

- There are numerous particles of hundreds of microns to zero microns in oil, and industrial filters can not eliminate particles contaminated below 10 m, and precise filtration can only be filtered to 5 m. Analysis of the content of contaminated particles in oil, the smaller the particle content, and if more than 1 mu of M pollution particles were set to 100%, then the content of pollution particles above 10 mu m is only 10%. That is to say, in general, the filter based oil purifier can only filter less than 10% of the contaminated particles, and our company's electrostatic oil purifier can effectively remove 0.1 M of contaminated particles.

1. Manufacturer Overview

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Blown Film Extrusion Machine/Plastic Blow Film Machine/PE Plastic Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords