PC Cap Making Machine Application for LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PC Cap Making Machine Application for LED Light

LED Light PC Cap Making Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automatic PC Cap Making Machine rate of quality goods is above 99%.

LED Light PC Cap Making Machine Technical Characteristic:

LED Light PC Cap Making Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

LED Light PC Cap Making Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

LED Light PC Cap Making Machine Parts Picture:

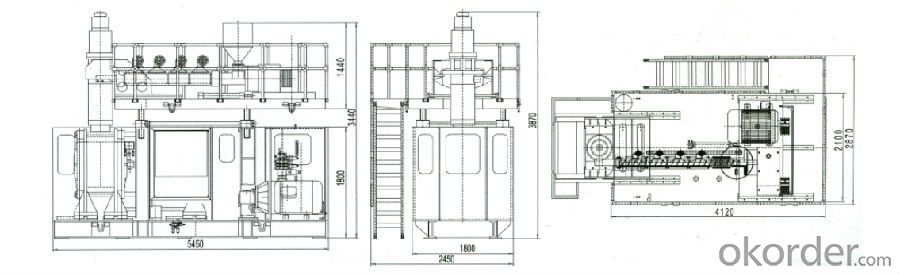

LED Light PC Cap Making Machine Drawing Picture:

LED Light PC Cap Making Machine Electrical Parts Photo:

LED Light PC Cap Making Machine Products Photo:

- Q:What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Ordinary plate oil filter is composed of filter bed, pump motor and coarse filter element, filter bed is composed of multi level filter plate and the filter frame, filter paper or cloth lining the filter plate and the filter frame, with pressure filter pressing device, the filter chamber is fixed independently formed between the plate and the filter frame is pressed in between the filter plate and the filter frame of the paper or cloth to play the role of filtering. The heating plate oil filter is independent heating device based on general frame increase oil filter, to filter high viscosity oil, oil filter plate ordinary machine is not filtered for high viscosity oil.

- Q:Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- Therefore, the plate and frame oil filter basically can only filter impurities, moisture and gas impurities, plate and frame oil filter is powerless. Multifunctional oil purifier belongs to the vacuum oil filter, vacuum oil purifier is designed according to the boiling point of water and oil in different principle, it is composed of vacuum heating tank filter, a condenser, a primary filter, water tank, vacuum pump, drainage pump and electric cabinet. Vacuum pump to vacuum tank air to form a vacuum, outside the oil under the influence of the atmospheric pressure through the entrance pipe into the primary filter, remove larger particles, and then into the heating tank, after heating the 40~75 C oil through the automatic oil float valve, the valve is automatically controlled in a vacuum tank the amount of oil import balance. The heated oil is rapidly rotated through the jet wings to separate the oil into a half mist. The water in the oil evaporates rapidly into steam and is pumped into the condenser continuously by vacuum pumps. The steam enters the condenser after cooling back into the water discharge, oil heating in vacuum tank, pump are arranged into the filter through the filter or filter will filter out particulate impurities, thus completing the vacuum oil filter quickly remove impurities, the whole process of water and gas in oil, clean the oil from the oil discharge machine.

- Q:How much is the 90 screw frying machine?

- The following aspects mainly determine the price of the oil press.Screw oil press diameter, diameter, the greater the speed of work, the higher the price.

- Q:What is the reason for the fuel injection of the turbine vacuum pump?

- Vacuum pump exports of oil eventually derived from vacuum separation tank, the reasons are: 1, the treatment of oil is too bad, too much moisture in the oil, vacuum tank separation of water is too much

- Q:How is the plate type oil filter put into operation?

- I'm not sure what you are asking. This is specific. You can ask Taizhou HUAWEI. They have been making oil filters for many years

- Q:Transformer oil filter can be rented there

- This depends on whether you have local counterparts or nearby factories, substations and other enterprises may use transformer oil, if they have bought nearly ZYA transformer oil filter, it may rent you. Or through acquaintances, know that you have near the enterprise used to filter oil, idle unused, you may rent. However, the cost of renting the oil filter may be a little high, depending on how much oil you filter. I have heard of some users renting oil filters, 2000-3000 yuan filtering a barrel, and how many liters of a barrel of oil are not very clear.

- Q:How can I get rid of the cooking oil and the sediment filtered out by centrifugal oil filters?.

- Filter edible oil with centrifugal oil filter, plate and frame oil filterIf this occurs the landlord said, after filtering the edible oil and sediment, you can add a ladle, which is in the oil filter net exports, in order to avoid the filtered oil dirty and precipitation, which also adds a layer of filter.

- Q:How does the oil filter usually be repaired and maintained?

- Then place it where it is not easy to damp and dry. As for the maintenance of oil filters, specific conditions should be analyzed and treated.

- Q:What's the name of the glass tubing that filters the oil-water separation?

- Liquid level meter, you can clearly see the oil and water stratification.

- Q:Transformer oil filter how to choose?

- We must remember that ultra-high voltage transformer oil for 500KV ultra high voltage transformer and a similar demand for electrical power equipment for insulation and cooling medium, oil detection by SH0040-91 industry standards, test items include appearance, color, density (20 degrees Celsius), viscosity, aniline point, freezing point, pour point, flash point, and value, corrosive sulfur, water soluble acid and alkali, oxidation stability (precipitation, acid), breakdown voltage, dielectric loss factor (90 degrees Celsius), interfacial tension, trace water, condensate gas ratio dispersion. Hope to help

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PC Cap Making Machine Application for LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords