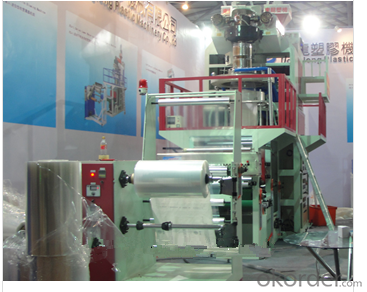

Two-layer Co-extrusion Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: What is the effect of the oil filter on the filtration of fine particles?

- Can filter, filter media to understand the industrial products, chemical properties of oil, liquid filtration requirements, now there are many ways of using the corresponding filtering method to deal with (such as: membrane filtration, fine filtration, ceramic filter, activated carbon filter, silica gel filtration and clay filter)

- Q: What's the name of the glass tubing that filters the oil-water separation?

- Liquid level meter, you can clearly see the oil and water stratification.

- Q: How does the vacuum oil filter protect the transformer?

- In fact, oil filter does not play any role in transformer protection, protection of the transformer is the transformer oil, insulation and fire resistance to transformer oil, so not in transformer oil containing water and impurities, and the need for water and filter impurities in the oil filter, so that it can select the vacuum filter oil filter machine, of course, the effect is good or bad, double-click the vacuum oil filter machine Xinxiang Younaite recommendations, the effect will be better.

- Q: Why does the vacuum oil filter tank foam?

- 3: turbine EH oil has cracked, can not be reused. EH steam turbine oil long-term operation at high temperature, some low molecular groups in the oil additive to volatilize, anti foam agent have disappeared, with the passage of time, oxidation strengthening, oil viscosity increases, the oil film strength also increased, gas permeability variation, provided the conditions for the formation and stability of foam the existence of. Waste oil which can not be reused at this time should be abandoned. In general, the vacuum oil filtration system prolongs the service life of various types of oil in the steam turbine system for 2-3 years, and is not indefinitely extended.

- Q: What are the main use of oil filters?

- Oil filters are mainly used in power, petrochemical, aviation

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- The oil purifier basically eliminates impurities, and the purifier can also remove water except for impurities, but the average person thinks it is the same

- Q: Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The accuracy of the filter is improved to a certain extent, and the new type of centrifuge has better rotation mode and transmission speed and higher centrifugal rate, so the filtering effect is also improved, and the filtering effect is improved in general.

- Q: Consult an expert, power plant turbine oil vacuum filter oil machine, why use ah, seems to be useful, poly junction separation, what are the advantages and disadvantages, thank you, urgent,

- Coalescence type oil filter function to small droplets into large drops of water, only to remove non dissolved water, so only the oil in the water treatment by 180mg/L, cannot meet the requirements of national standard, but if the oil moisture content is very high, the dehydration rate of coalescence separation is faster.In short, if Water Leakage oil measuring system is relatively small, should be a vacuum oil filter, can make the turbine oil quality to meet national standards. If the water leakage is large, optional poly separation type, but can not make the oil to meet the requirements of gb.

- Q: What is the difference or connection between the oil filter and the oil filter?

- Second, the oil filter is usually fixed to a part of the system, and the oil filter is usually a mobile filter unit, without the need for fixed installation,

- Q: Double barrel automatic electric heating centrifugal oil filter and oil separation automatic horizontal centrifugal oil filter which is better than

- So it depends on what your oil is, and then come to choose the oil filter, you can Baidu Cleansing Oil Wang filter, which can refer to the next

Send your message to us

Two-layer Co-extrusion Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords