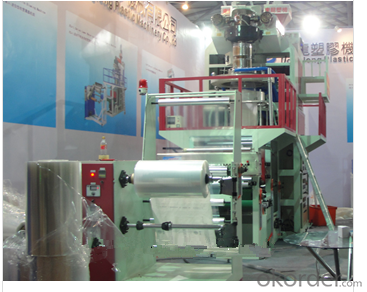

Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: What is the working vacuum in the oil filter?

- The vacuum tower is the core reaction device of vacuum oil filter, filter water main device in this trace, according to oil, water, gas heating in vacuum environment, the flash point of different transformation time, thus the separation of different material form. Separation is the key to control the vacuum heating, vacuum must be controlled in a certain complete gas-liquid separation and oil-water separation is within the scope of work ability, the vacuum degree is -0.06 ~ -0.095Mpa.

- Q: Can the filter core be made to order?

- Oil filters on the oil press are generally divided into three kinds

- Q: What are the main use of oil filters?

- Gas stations, oil producing enterprises, etc., as long as the used oil can be used

- Q: Application of vacuum oil filter

- The common transformer oil vacuum oil filter can be used independently, and can also be used in conjunction with the oil regeneration system

- Q: Difference between low speed and high speed of centrifugal oil filter

- High speed centrifuge is the main filtration principle of centrifugal oil filter of the centrifugal force generated, so as to realize oil-water separation and oil separation

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- The oil purifier basically eliminates impurities, and the purifier can also remove water except for impurities, but the average person thinks it is the same

- Q: What should be noticed when using an oil filter?

- Should be strictly in accordance with the instructions provided by manufacturers, so as not to cause unnecessary damageFiltration of cooking oil must pay attention to environmental hygiene and personal hygiene of operators, prevent all kinds of dust, ashes, dirt and other brought into, and pay attention to disinfection, sterilization, clean use space.

- Q: Does the vertical centrifugal oil filter have any residue in the filtered oil?

- See what oil you want to filter, and then choose the oil filter is better

- Q: I opened a small youfang! The oil used in centrifugal oil filters is always mixed

- First of all: you open a small oil mill, then the general is the filtration of edible oil, edible oil filter using centrifugal oil filter is possible, but must be stainless steel, but also need to use 304 stainless steel.Second: the centrifugal oil filter mainly used high speed centrifuge to produce centrifugal force, and comprehensive settlement, such as the centrifugal filtration of water and impurities, according to your description after filtration or turbidity, the oil filter did not play a role, reasons are analyzed as follows:

- Q: How is the plate type oil filter put into operation?

- Open the door once, open the door two times, open the exit door, open the oil filter. Look, the oil filter has two inlet doors to adjust the pressure

Send your message to us

Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches