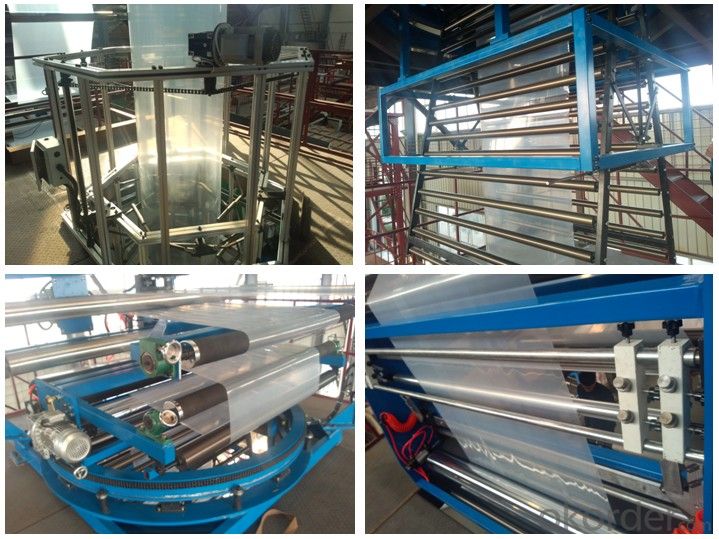

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1, Main Technical Parameters

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

2, Configuration

2.1 Extrusion system (Extruder)

Equipped with 5sets of SJ55x32 and 2set of SJ65x32 single screw extruder which have

advantages of good production efficiency, low energy

consumption and good plasticization.

2.2 Die head system

Die head is introduced the advanced German technology, through CAD optimal design,

processed with German TC2.8K four-axis simultaneous machining center. The die will have

features of high precision, good brightness without deformation.

2.3 IBC system

IBC (ultrasonic closed-loop servo-control) system is consists of gas exchange device,

internal cooling air ring, in/out air blower, signal detection and control circuits, etc. The

system can rapidly cooling the bubble, exhaust inner heat, water molecules and emissions

of bubble, supply new cooling air, cool the inner temperature of the bubble, increase the

production output and improve the mechanical properties of films.

2.4 Traction system

Horizontal ±360°reciprocating rotary can guarantee the linear velocity of film product

always stay consistent. The driving mechanism, haul off device and V-shaped plate hauls

the bubble for 360°uniform rotary at the speed of 0.1-0.3r/min to make the film deviation

which caused by die head, air ring and tower frame being 100% randomly distributed, thus,

to guarantee the whole quality of formed film product.

2.5 Automatic winding system

With the features of advanced technology, safe operation, easy maintenance, the winding

system can automatically change, cut and unload the rolls, which highly reduces the labor

costs and enhances the effectiveness.

2.6 Computer control system

Control method: Mitsubishi PLC control technology

2.6.1 One set of main control cabinet, adopts one set of three-in-one cabinet. (AC

contactor, low voltage fault positioner from Schneider, SSR from Taiwan Yangming)

2.6.2 Display part: adopts 10.4" touch screen for the operation (traction, winding, metering,

IBC, synchronous tension, cooling control of inlet/outlet blower).

2.6.3 Yaskawa frequency inverter for extruder motors, and domestic frequency inverters for

the rest.

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- In the filter to filter out large particles of impurities in oil, but can not filter out the compound emulsion regeneration and oxide molecular structure, often need to pay attention to clean the filter in the process of using, easily broken or blocked.

- Q: What is the trouble with the vacuum pump used in the oil filter? How can it be removed so that the oil filter works properly?

- The vacuum pumps used in oil filters usually do this:1. the exhaust of the vacuum pump is smoke;2. vacuum pumps, oil spills, oil spills;3. vacuum pump noise exceeds standard;4. vacuum decrease;5. vacuum pump, hot and so on;

- Q: What is the difference between an oil filter and an edible oil refinery? Is it the same device? How about the price? Is it a big difference? I want to buy one useful,Good to Luhua peanut oil level. Please give me your advice. Thank you very much.

- The processed oil can go directly to supermarkets and sell in batches. A set of edible oil refining equipment ranges from tens to hundreds of millions.

- Q: Why does the vacuum oil filter tank foam?

- 1: the fuel tank return port is improperly set, resulting in two gas mixing. Generally, the condensate gas tank, precipitation, slag falling settlement, oil return port is arranged below the surface of oil, the oil from the high drop into the tank, increase the chance of air into the oil, also caused a stir, let the water back by gravity sedimentation oil layer, bubble generation.2: steam turbine system design flaws or system aging and other man-made EH steam turbine oil system with steam or water, then will cause the oil emulsion, oil emulsion into the vacuum distillation tower, high temperature vacuum evaporation, bubble, if EH oil vacuum filter without defoaming or eliminating system bubble device damage will lead to the bubble with the oil into the tank to cycle.

- Q: The working principle of centrifugal oil filter

- Through the high-speed rotation of the centrifugal force of the drum and the dregs of oil to leave, liquid-solid separation. When the rotary drum stops rotating, the net oil is slid out of the drum to achieve the purpose of filtration. The oil quality is pure, and the experiment can be done on the fire at the time, fried fritters, stir frying dishes, no foam, no overflow pot. In the past we have used filtration equipment such as: frame filter, vacuum filter, pressure filter is called filter medium (media refers to the cloth, filter, filter cloth mesh) because the medium level of large dregs filtration process is filtered out, small particles through the mesh flow to the oil. This is the past, the filtration effect is relative to solve the quality issues, in operation, the crude oil inside the oil to plug the glial mesh after repeatedly opening the replacement of the filter cloth, cleaning cloth and post consumption.

- Q: What is the reason for the oil running out of the turbine oil filter?

- When the viscosity of the oil becomes larger, the oil quantity in the lower part of the vacuum tank is reduced through the filter screen, resulting in the liquid level switch not reaching the action value, and the oil inlet pump fails to stop together, resulting in continuous oil spill at the vacuum pump outlet.After the temperature of sealing oil is lower, the main reason of this event is that the mechanical and electrical heater of oil filter is not automatically put into operation

- Q: What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Characteristic:1, super demulsification dehydration and degassing system, with large volume, enhanced three-dimensional flash tower and thin film evaporation technology and a large area of multi-level oil water gas separation technology, can fast remove the oil in the water, gas and light hydrocarbon.2, the use of high quality filter original and sealing materials, corrosion resistance, high temperature resistance, good mechanical strength, to meet the high viscosity of the filter oil needs higher temperature requirements, expanding the range of its purification of oil.3 、 precise multi-stage filtration system can effectively remove mechanical impurities in oil.4 、 advanced pressure protection device, liquid level control system, to avoid the misoperation of the equipment.5 、 perfect automatic and manual electric heating temperature control device, automatic separation cooling device, simple operation, safe and reliable.6, the machine can also be used to meter and timers, users can carry out automatic measurement of fuel quantity and working time.

- Q: Method for using negative pressure oil filter

- The filter area of the oil filter is larger, the vacuum pump is also increased, and the oil filtration rate is much faster

- Q: Oil filter ZLA-20! During the test process! Foam! How can you remove the foam?! I'll vacuum it a little bit, and the bubble will be better! however

- Who should have cheated you on this return?. Recommended ZYAXD-100 two-stage vacuum, automatic defoaming, definitely better than any ZLA

- Q: Characteristics of vacuum oil filter

- Vacuum oil filter, also called vacuum oil filter, oil filter, vacuum oil purifier which has the characteristics of small volume, light weight, easy to move, the proportion of low noise, long continuous operation, stable performance, convenient operation etc.. Is the ideal equipment for the power plant, power plant, substation and electric appliance manufacturing plant, refinery, petrochemical and other industrial and mining enterprises and filtration of transformer oil, turbine oil, hydraulic oil, 40# oil in water, gas and impurity particles

Send your message to us

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches