HDPE LDPE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

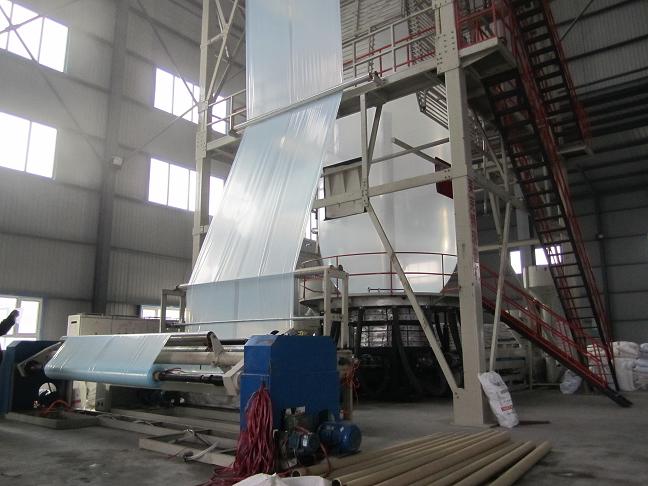

This film blowing machine is suitable for blowing the plastic film as high density Polyethylene (HDPE), low density Polyethylene (LDPE) and linear low density Polyethylene (LLDPE), which is widely used for packing foodstuff, garment, textile, daily-use articles and industrial products etc. It can produce pearl film and degradation film via making up a prescription. This kind of machine is the widest use in the market at present and it's the preferred machine for building a film-blowing factory.

Characteristic:

1. The screw and cylinder are made of 38CrMoAl high quality alloy steel after fine finishing and nitrided treatment, which has high hsrdness, srrong resistance to corrosion, durable service.

2. The die head is plated with hard chrome, of screw mandrel type structure with even and smooth discharging, the blown plastic film has fine finishing; The blower is of labyrinth structure with even air output.

3. The coiling unit adopts pressure friction rewinding or center rewinding, which is driven by torque motor, with even and smooth rewinding and easy roll changing.

Technical Parameters:

| Type | 45 | 50 | 55 | 60 | 70 | 80 | 85 | 90 | 110 | 110-2 | |

| Diameter of Screw(mm) | Φ45 | Φ50 | Φ55 | Φ60 | Φ70 | Φ80 | Φ85 | Φ90 | Φ110 | Φ110 | |

| L/D ration of screw | 30:1 | ||||||||||

| Specification of Die Head | Φ40 -100 | Φ60 -130 | Φ70 -160 | Φ90 -200 | Φ110 -250 | Φ200 -300 350 | Φ200 -350 | Φ400 -500 | Φ400 -600 | Φ400 -900 | |

| Thickness of Products(mm) | 0.004-0.08/0.025-0.15 | ||||||||||

| Folding width of Products(mm) | 100 -600 | 100- 800 | 100- 1100 | 100- 1200 | 200- 1500 | 200- 1600 | 200- 1800 | 200- 2000 | 200- 2500 | 200- 4000 | |

| Main power(kw) | 12 | 18 | 22 | 22 | 22 | 30-37 | 37-45 | 37-45 | 55-75 | 75× 2 | |

| Max. Output(kg/h) | 30 | 35 | 50 | 60 | 80 | 70-100 | 100-130 | 180 | 280 | 450 | |

| Weight(T) | ≈1.6 | ≈1.8 | ≈2.0 | ≈2.2 | ≈4 | ≈4.5 | ≈5 | ≈6 | ≈6.5 | ≈8 | |

| Overall Dimensions(L× W×H) )(m ) | 3.6× 1.5 × 3.5 | 4×1.9×3.8 | 4.1×2×4.3 | 4.2×2.2×4.5 | 5× 2.7× 5.5 | 5.3× 2.9× 6 | 6× 3.1 × 7 | 7× 3.3× 7.5 | 8× 3.8 × 9 | 9× 3.5× 15 | |

- Q: Where has the waste lubricating oil to come in, it is the oil filter of the finished oil

- But you call into oil means nothing more than to sell, not in repeated use, the oxidation of colored substance is soluble in oil cannot be filtered through ordinary oil filter, that is filtered to decolorization. You said the so-called "waste oil into refined oil" is not possible, to become the so-called refined oil, must decolorization, some of the products of domestic only through clay, activated carbon and other similar material to absorb, but even if the color change can not be used directly, through adsorption oil additives has been lost only, from the new processing additives can become a refined oil

- Q: How does the vacuum oil filter protect the transformer?

- Filter the moisture or impurity of the transformer oil to ensure the normal operation of the transformer! Of course, in general, transformer oil is generally relatively clean, as long as it is possible to accumulate my moisture on the performance of transformer oil, causing security risks. So it is the best way to protect transformer oil by choosing a transformer transformer of ZL transformer for processing transformer oil.

- Q: What are the considerations for selecting an oil filter?I am the company procurement, workshop to buy oil filters, selected a lot of homes, almost all, a little bit Mongolia, specifically what should pay attention to ah?

- 2. Know the total amount of oil to be filtered, and select the appropriate oil filter (how many liters per minute)3, mobile or fixedWhere are you from?

- Q: When the centrifugal oil filter is used to filter peanut oil, the oil color is black and cloudy. What's the matter?

- The centrifugal filter can filter the cooked peanut oil. Raw peanut oil, too low temperature, filtration effect is not good

- Q: What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Ordinary plate oil filter is composed of filter bed, pump motor and coarse filter element, filter bed is composed of multi level filter plate and the filter frame, filter paper or cloth lining the filter plate and the filter frame, with pressure filter pressing device, the filter chamber is fixed independently formed between the plate and the filter frame is pressed in between the filter plate and the filter frame of the paper or cloth to play the role of filtering. The heating plate oil filter is independent heating device based on general frame increase oil filter, to filter high viscosity oil, oil filter plate ordinary machine is not filtered for high viscosity oil.

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- In addition to the impurities in the oil, the purifier can also separate the moisture in the oil. The oil filter is only a simple filtration of impurities.

- Q: How does the vacuum oil filter remove moisture and loss?

- Strong wind condenser and vacuum buffer chamber, water vapor and condensable gas are condensed and removed by drainage device. Non condensable gas is discharged by vacuum pump. Finally, the oil, which removes water, gas and mechanical impurities, is pumped into the precision filter by the oil pump to remove the particulate impurities in the oil, which is clean oil and complete the whole oil purification process.

- Q: What is the accuracy of 300*300 oil filter paper for LY-100 plate and frame pressure oil filters?

- The filtering accuracy of filter paper is only concerned with the material of filter paper, the production process and the power of fiber weaving of filter paper.

- Q: Consult an expert, power plant turbine oil vacuum filter oil machine, why use ah, seems to be useful, poly junction separation, what are the advantages and disadvantages, thank you, urgent,

- The vacuum oil filter has more water - retaining functions than the ordinary oil filter, because it has the function of water diversion, so as to use it. The role of turbine oil is to lubricate and cool the bearing of the turbine. The oil is easy to enter steam because of its location and the position of the steam seal. Resulting in water, water, resulting in deterioration of oil quality. To slow down the oil quality, say to get rid of the water in the oil. The oil filter that you put together has not been used or seen, and I don't know its advantages and disadvantages, but I think it is a water filter that can remove water. Hope to be of help to you

- Q: Pressure filter and vacuum oil filter how to choose, prompt only know productivity Q

- The principle of electrostatic oil filter on the basis of attraction, using the Z potential of oil and water, colloid impurities, mechanical impurities and other impurities particles are different, when the impurity particles with the oil flow to the high pressure electrode plate, which quickly swim towards the opposite electrode direction, and is attached to the filter dirt between the upper electrode plate. At the same time, under the influence of static electricity, the impurity particles attached to the dust filter can also attract other impurity particles like the iron filings in the magnetic field. The separation principle has nothing to do with the size of the pollutant, but is related to the Z potential of the separated object.

Send your message to us

HDPE LDPE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords