Reinforced Hdpe Geomembrane

Reinforced Hdpe Geomembrane Related Searches

Geomembrane Hdpe Hdpe Textured Geomembrane Reinforced Geomembrane Geomembrane In Hdpe Hdpe Geomembrane Machine Wholesale Geomembrane Hdpe Hdpe Smooth Geomembrane Wholesale Hdpe Geomembrane Hdpe Geomembrana Geomembrana Hdpe Gse Hdpe Geomembrane Hdpe Geomembrane Installation Hdpe Geomembrane Welding Hdpe Geomembrane China Geomembran Hdpe Hdpe Geomembrane Specifications Geomembrana De Hdpe Hdpe Membrane Hdpe Geomembrane Sheet Geomembrana In Hdpe Hdpe Geomembrane Factories Wholesale Hdpe Geomembrana Jual Geomembrane Hdpe Solmax Hdpe Geomembrane Wholesale Liner Hdpe Geomembrane Kolam Geomembrane Hdpe Solmax Geomembrane Hdpe Hdpe Geomembrane Self Adhesive Hdpe Geomembrane Manufacturers Hdpe Geomembrane SuppliersReinforced Hdpe Geomembrane Supplier & Manufacturer from China

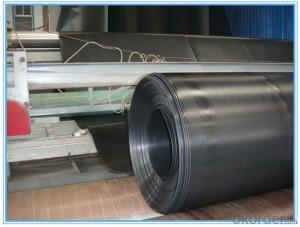

Reinforced HDPE Geomembrane is a high-performance geomembrane product that combines the strength of a high-density polyethylene (HDPE) core with a reinforcement layer. This composite material is designed to provide excellent chemical resistance, puncture resistance, and durability, making it ideal for a wide range of applications in the environmental and construction industries.The reinforced HDPE geomembrane is widely used in various applications, such as landfill liners, wastewater treatment ponds, reservoirs, and other containment structures. Its versatility allows it to be employed in both civil and environmental engineering projects, where its impermeable properties help prevent the leakage of pollutants and contaminants. The product's robustness also ensures that it can withstand the harsh conditions often encountered in these settings, making it a reliable choice for long-term projects.

Okorder.com is a leading wholesale supplier of reinforced HDPE geomembranes, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the reinforced HDPE geomembranes they provide meet the highest standards of performance and reliability. Their extensive stock allows customers to access this essential product quickly and efficiently, ensuring that projects can proceed without delays due to material shortages.

Hot Products