HDPE Impermeable Waterproof Composite Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Geomembrane can be divided according to the different materials HDPE geomembrane , matte geomembrane , LDPE geomembrane , LLDPE geomembrane , EVA geomembrane , ECB geomembrane , PVC geomembrane.

Product Use

1, City landfill ;

2, Roads, railways , drainage , irrigation , tunnels, dikes, dams , gates seepage, seepage accumulator library ;

3, Fluid channels , solid manure dumps impermeable ;

4, impermeable roof , building basements, underground storage , underground garage moisture ;

5, pile cofferdam film , land reclamation from the sea , marina projects etc.

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geomembranes be used for gas containment?

- Yes, geomembranes can be used for gas containment.

- Q: What factors should be considered when selecting a geomembrane?

- When selecting a geomembrane, several factors should be considered. These include the type of application or project, the environmental conditions, the required lifespan and durability, the chemical compatibility with the surrounding materials, the installation and maintenance requirements, and the cost-effectiveness. Additionally, factors such as UV resistance, puncture resistance, flexibility, and ease of welding or seaming should also be taken into account. It is crucial to carefully assess these factors to ensure the chosen geomembrane meets the specific needs and demands of the project.

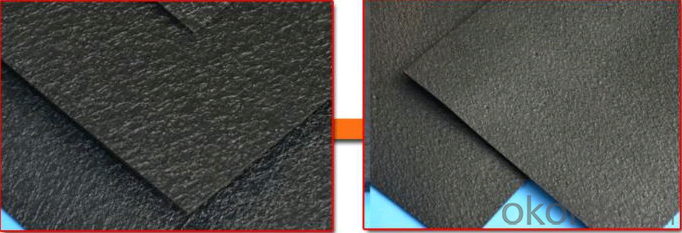

- Q: What is the difference between a smooth and textured geomembrane?

- A smooth geomembrane has a flat and even surface, while a textured geomembrane has a rough or patterned surface. The choice between the two depends on the specific application and desired functionality. The texture in a geomembrane enhances friction and provides increased stability, making it suitable for applications where slope stability is important or when the material needs to resist slipping. On the other hand, smooth geomembranes are typically used for applications where a low coefficient of friction is desired, such as in containment systems where sliding of the material is necessary for proper functioning.

- Q: What is made of stretch film?

- Composite stretch film is currently the most widely used and largely consumed, occupying more than 40%of the overall consumption of plastic packaging stretch film. Since polyethylene containing no polar group has high crystallinity and low surface free energy, so surface treatment is required before printing and composite. Low density polyethylene stretch film is translucent, shiny, soft. It has excellent chemical stability, heat sealability, water resistance and moisture resistance, freeze-resistant and it can be boiled. Generally low density polyethylene stretch film is made by blow molding and curtain coating. polyethylene stretch film made by curtain coating is of uniform thickness, but is rarely used because of high prices. Blow-molded polyethylene stretch film is made by PE particles blown from the blow molding machine. It is most widely used for its low cost. Stretched polyester film is using polyethylene terephthalate as raw material, It is colorless, transparent, glossy stretch film, excellent mechanical properties, high stiffness, hardness and toughness, puncture resistance, abrasion resistance, high temperature and low temperature resistance. It has good chemical resistance, oil resistance, air tightness and fragrance holding. it is one of film substrate of the commom composite stretch film that is permeability resistance. But polyester stretch film price is higher, generally having a thickness of 12μm, often used for outer materials of cooking and packaging. it prints well.

- Q: How to choose the glass stick membrane Sunscreen film?

- How to choose the glass stick membrane Sunscreen film: 1. From the abrasion resistance, it can be divided into low abrasion resistant coating layer, wear-resistant layer and not wear-resisting film. So after we get a piece of architectural membrane, the first is to distinguish its protective layer, and then rub it on the wear-resistant layer to see if it will produce pattern. If there is the decorative pattern, it is the low level; If there isn't the decorative pattern, it is the middle or high level film. 2. To see whether there is electrostatic attraction, due to the low membrane uses a little metal materials. So when it is being rubbed, it will slide from left to right; but to the high-end film, it has a kind of electrostatic attraction due to it with a lot of metal materials, and it is not sliding when rubbing. 3. The first is to see whether the plating layer is uniform, pick up a piece of building film to see whether it is uniform. If it is even, it is the good quality film. If it is uneven, it is the low quality film. 4. According to the analysis, because the heat insulation effect of different grades of film solar is not the same, so we adopt the high power lamp (500W--700W) to irradiate on the surface of the membrane. If the insulation effect of the low-grade membrane is poor, the hot will be felt even across the film. But for the high-end film, there is hardly any calorie that can penetrate it, so the hot will not be felt across the membrane. 5. The carburetor cleaning agent test method is to make the floor friction or the oil cleaning agent with a piece of film (also known as "cleaning agent") spray on the membrane. The fading inferior film is usually said tinted film. The film not fading is the high-end film, also known as the film of primary color. In summary, the building film with high transmittance and high thermal insulation is the high-grade film.

- Q: Are geomembranes suitable for use in mining operations?

- Yes, geomembranes are suitable for use in mining operations. They are often used as liners in tailings ponds, heap leach pads, and other containment structures to prevent the escape of mining by-products into the environment. Geomembranes provide an impermeable barrier, effectively containing liquids and preventing contamination of soil and groundwater. Additionally, they are resistant to chemicals and UV degradation, making them highly durable in harsh mining conditions.

- Q: Can geomembranes be used for reservoir lining?

- Yes, geomembranes can be used for reservoir lining. They are commonly used in reservoir lining applications to prevent seepage and leakage of water. Geomembranes provide a barrier that helps to maintain the water level and prevent contamination of the reservoir.

- Q: Can geomembranes be used in hydraulic applications?

- Yes, geomembranes can be used in hydraulic applications. Geomembranes are impermeable liners made of synthetic materials like PVC, HDPE, or LDPE, which can effectively prevent the seepage of water or other fluids. They are commonly used in hydraulic applications such as reservoir lining, pond lining, canal lining, and as barriers in landfills or wastewater treatment systems. Geomembranes provide excellent resistance to hydraulic pressure, chemical corrosion, and UV exposure, making them suitable for various hydraulic engineering projects.

- Q: Does the lower geotextile of composite geomembrane need seaming?

- In general, it does not need to seam (extending and folding together is ok). You only need to weld the geomembrane and seam the upper geotextile with handheld sewing machine. Geotextile is used as a protective layer of geomembrane to protect the impervious layer from being damaged. In order to reduce the ultraviolet radiation and increase the anti aging performance, you'd better use buried laying method. During construction, first, level cardinal plane with small sand or clay, then pave. Do not stretch too tight when paving. Both ends buried in soil is corrugated. Finally, pave a transition layer of about 10cm with fine sand or clay on two cloths and one membrane and build scour prevention layer with 20-30cm stone (or precast concrete block). In construction, you'd better build the packaging layer while paving membrane edge to try to avoid the stones hit directly on it. The connection between two cloths and one membrane and surrounding structures should be anchored by expansion bolt and steel plate depression bar, painted with emulsified?asphalt (2mm thick) to stick and prevent leakage. Construction joint treatment is a key process, which directly affects the anti-seepage effect. General joint methods are: ① lap: lap width should be larger than 15cm; ② hot?welding: suitable for thicker geomembrane substrates, and lap width of weld should be not less than 5cm.

- Q: How do geomembranes handle differential settlement?

- Geomembranes are designed to handle differential settlement by being flexible and adaptable to changes in ground conditions. They can conform to the movement of the underlying soil, minimizing the risk of tears or ruptures. Additionally, the installation of a geosynthetic clay liner or a geogrid can provide additional reinforcement and stability to the geomembrane, allowing it to withstand differential settlement more effectively.

Send your message to us

HDPE Impermeable Waterproof Composite Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords