HDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and will provide an effective barrier to of liquid

water and water vapor.

Characteristics

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

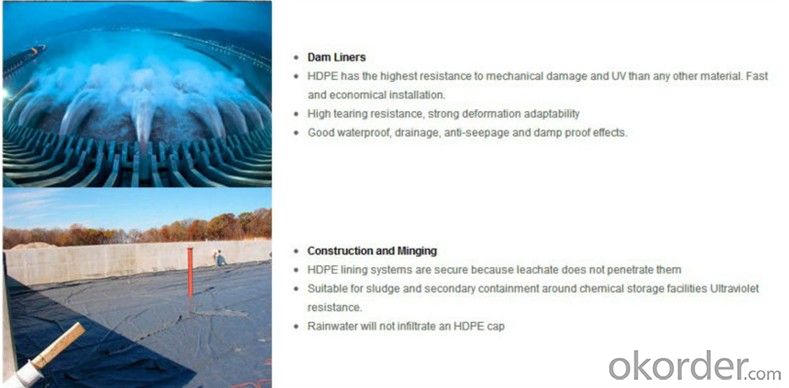

Features:

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

Application Rage

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q: Can a waterproofing membrane be used on steel surfaces?

- Indeed, steel surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically designed to establish a shield against moisture and water incursion, and they possess the versatility to be utilized on a range of surfaces, including steel. Construction endeavors, including roofs, balconies, and foundations, frequently feature steel surfaces. By employing a waterproofing membrane on these steel surfaces, one can effectively thwart corrosion and harm arising from water contact. It is crucial to carefully choose a waterproofing membrane that suits steel surfaces, while also adhering to correct surface preparation and application techniques to attain maximum performance and longevity.

- Q: On the roof of the waterproofing membrane paving the direction of what are the requirements

- ?As for the upper and lower layers are not allowed between the vertical paving, the reason is that after the paving more heavy joints, and heavy seam is the most vulnerable to leakage of weak parts. ????????Dragon waterproof experts to remind you: things always have a dual nature. In the southern region, the temperature is high, rainy days, to the web paving brought a lot of difficulties. In order to waterproof roofing, when the rain is easy to coil joints, in addition to less than 3% of the roof slope, the remaining slope of the roof coil should take the vertical roof direction paving.

- Q: Can a waterproofing membrane be used for foundation repair?

- Foundation repair can be achieved by using a waterproofing membrane. These membranes are widely utilized in order to prevent water infiltration and moisture damage in basements and foundations. The primary purpose of these membranes is to create a barrier against water and other forms of moisture, thereby safeguarding the foundation from further harm and potential structural issues. Applying a waterproofing membrane to the foundation can aid in the repair process by sealing existing cracks or leaks and preventing water from seeping into the foundation, which could lead to additional problems. Furthermore, the utilization of a waterproofing membrane can also reduce the risk of mold and mildew growth, as it decreases the moisture content in the foundation. Ultimately, the use of a waterproofing membrane is an effective technique for foundation repair as it ensures the long-term stability and durability of the foundation.

- Q: Are waterproofing membranes resistant to oil and grease?

- Yes, waterproofing membranes are often resistant to oil and grease. These membranes are designed to create a barrier against water infiltration, and many of them are also made to withstand exposure to various chemicals, including oil and grease. This resistance is typically achieved through the use of specialized materials and coatings that are able to repel or prevent absorption of oil and grease. However, it is important to note that the level of resistance can vary depending on the specific type and brand of the waterproofing membrane. Therefore, it is advisable to consult the manufacturer's specifications or seek professional advice to ensure the membrane chosen is suitable for the specific application and level of oil and grease exposure.

- Q: Is a waterproofing membrane resistant to freeze-thaw cycles?

- Yes, a waterproofing membrane is resistant to freeze-thaw cycles. This is because the membrane is designed to prevent the penetration of water, which can expand and contract during freeze-thaw cycles. The membrane acts as a barrier, preventing water from seeping into the structure and causing damage due to freezing and thawing. Additionally, waterproofing membranes are typically made from materials that are flexible and able to withstand temperature fluctuations without losing their effectiveness.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: Are there any specific considerations for installing a waterproofing membrane in high-traffic areas?

- Yes, there are specific considerations for installing a waterproofing membrane in high-traffic areas. Firstly, the membrane should be durable and able to withstand heavy foot traffic without getting damaged. It should also have a non-slip surface to ensure safety and prevent accidents. Additionally, the membrane should be easy to clean and maintain to prevent dirt build-up and maintain its functionality.

- Q: Is a waterproofing membrane compatible with different types of flooring materials?

- Different types of flooring materials can be used with a waterproofing membrane. The purpose of a waterproofing membrane is to create a barrier between the subfloor and the flooring material, preventing moisture from causing any damage. This means that it can be used with laminate, vinyl, tile, and even hardwood flooring. By using a waterproofing membrane, the flooring material will remain protected from water damage, allowing it to last longer and maintain its appearance. However, it is important to keep in mind that specific compatibility requirements may exist for different types of waterproofing membranes. Therefore, it is advisable to consult the manufacturer's guidelines to ensure the proper installation of the chosen flooring material.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are often used to protect various surfaces, including asphalt, from water damage. They create a barrier that prevents water from seeping into the asphalt, reducing the risk of cracks, deterioration, and other forms of damage caused by moisture.

Send your message to us

HDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords