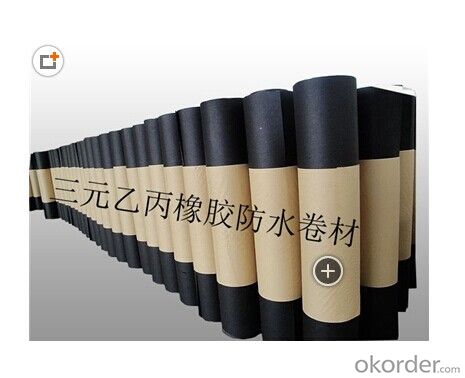

EPDM Rubber Waterproof Membrane with Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane--Top3 manufacturer in China

Detail Information for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility(-40degree to 150degree)

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Application for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm; 1.2mm;1.5mm;2.0mm | |||

Weight(kg/m2) | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

1.30-1.34 | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 | |

Length | 20m/Roll | |||

Width | 1.2m/2.05m/4.0m | |||

Usage | basements, ponds, Lake, steel structure roofing, underground, tunnels | |||

Packing | 24/41/80 sqm/roll | |||

Loading in Container | Rolls | |||

Colors | Black | |||

Technical Data for EPDM Waterproof Membrane

Item | value | ||

JL1 | JF1 | ||

Tensile Strength (Mpa) | normal tamperature | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

Elongation at break (%) | normal tamperature ≥ | 450 | 450 |

-20°C ≥ | 200 | 200 | |

Tear Resistance (N) | ≥ | 25 | 18 |

Water impermeability | 30mm | 0.3Mpa | 0.3Mpa |

Cold bending | (°C) ≤ | -40 | -30 |

Heating Shrinking rate | extand << span=""> | 2 | 2 |

shrink << span=""> | 4 | 4 | |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a hotel?

- Yes, a waterproofing membrane can be used for a hotel. Waterproofing membranes are commonly used in construction to protect buildings from water damage. In the case of a hotel, a waterproofing membrane can be applied to various areas such as the roof, foundation, basements, bathrooms, and balconies to prevent water leakage and moisture penetration. This is especially important in areas where water exposure is likely, such as swimming pools, spa facilities, or areas with heavy rain or high humidity. Installing a waterproofing membrane in a hotel can help maintain the structural integrity of the building, prevent mold and mildew growth, and ensure a comfortable and safe environment for guests.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. When applied to a surface, such as a wall or floor, the waterproofing membrane creates a barrier that prevents water or moisture from penetrating the surface. This often involves applying a coating or layer that can alter the texture or sheen of the surface. In some cases, the membrane may cause a slight color change or darken the surface. However, there are also transparent or colorless waterproofing membranes available that do not significantly alter the appearance of the surface. Ultimately, the impact on appearance will depend on the type of waterproofing membrane used and the desired aesthetic outcome.

- Q: Are waterproofing membranes resistant to seawater?

- Yes, waterproofing membranes are resistant to seawater. These membranes are designed to provide a barrier against water and are specifically engineered to withstand the harsh conditions of seawater. They are made from materials that are highly resistant to saltwater corrosion and are tested to ensure their effectiveness in preventing water penetration, including the corrosive effects of seawater. This makes waterproofing membranes an ideal choice for applications where seawater exposure is a concern, such as in marine structures, coastal buildings, and swimming pools.

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Yes, a waterproofing membrane can be used on breeze block surfaces. Breeze blocks, also known as concrete blocks, are commonly used in construction and have a porous nature. This allows water to seep through the blocks, potentially causing dampness or water damage in the building. To prevent this, a waterproofing membrane can be applied to the surface of the breeze blocks. A waterproofing membrane is a thin layer of material that is designed to prevent water penetration. It acts as a barrier, preventing water from seeping into the breeze blocks and protecting the underlying structure from moisture damage. The membrane is typically applied in liquid or sheet form and is adhered to the surface of the breeze blocks using an appropriate adhesive. Before applying a waterproofing membrane, it is important to properly prepare the breeze block surface. This may involve cleaning the surface and ensuring it is free from any loose debris or contaminants. Additionally, any cracks or gaps in the breeze blocks should be repaired prior to applying the membrane to ensure a seamless and effective waterproofing system. It is worth noting that the type of waterproofing membrane used will depend on the specific requirements of the project and the conditions the breeze block surface will be exposed to. There are various types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, or cementitious coatings. It is recommended to consult with a professional or manufacturer to determine the most suitable waterproofing membrane for your specific application. In conclusion, a waterproofing membrane can be used on breeze block surfaces to effectively prevent water penetration and protect the underlying structure from moisture damage. Proper preparation of the surface and selection of the appropriate membrane type are important factors to ensure a successful waterproofing solution.

- Q: Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can be used on shower walls. These membranes are specifically designed to create a barrier against water, preventing leaks and protecting the underlying structure from moisture damage. Applying waterproofing membranes on shower walls is a common practice to ensure a watertight and durable shower enclosure.

- Q: Can a waterproofing membrane be used for bridge abutments?

- Yes, a waterproofing membrane can be used for bridge abutments. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect structures from moisture damage. Bridge abutments, as critical components of bridge infrastructure, can benefit from the installation of a waterproofing membrane to ensure long-term durability and structural integrity.

- Q: Can a waterproofing membrane be applied on a sloped surface?

- Yes, a waterproofing membrane can be applied on a sloped surface. In fact, applying a waterproofing membrane on a sloped surface can be even more critical than on a flat surface. Sloped surfaces tend to have more water runoff, which can increase the risk of water infiltration and damage to the underlying structure. By applying a waterproofing membrane on a sloped surface, it helps to create a barrier that prevents water from penetrating into the structure and directs it towards drainage systems. However, it is important to ensure that the membrane is properly installed and adhered to the slope to prevent any potential issues such as water pooling or membrane detachment. Additionally, the type of waterproofing membrane used should be suitable for sloped surfaces and have the necessary flexibility to accommodate any movements or shifting that may occur.

- Q: Does a waterproofing membrane affect the structural integrity of a building?

- No, a waterproofing membrane does not affect the structural integrity of a building. Its primary function is to prevent water penetration and protect the building from moisture damage, without compromising the overall strength or stability of the structure.

- Q: Can waterproofing membranes be used in cold climates?

- Waterproofing membranes are applicable in cold climates. They are specially engineered to safeguard against moisture and water infiltration in diverse weather situations, including cold temperatures. These membranes are commonly constructed from sturdy and pliable materials that can endure freezing temperatures without fracturing or declining in quality. Furthermore, certain waterproofing membranes incorporate supplementary characteristics such as thermal insulation, which aids in preventing heat loss and upholding a cozy indoor atmosphere in cold climates. All in all, waterproofing membranes serve as a successful remedy for guaranteeing the soundness and durability of structures in cold weather circumstances.

- Q: Can a waterproofing membrane be used for train platforms?

- Yes, a waterproofing membrane can be used for train platforms. Waterproofing membranes are commonly used in construction to provide a protective barrier against water and moisture. By applying a waterproofing membrane to train platforms, it helps prevent water ingress, which can cause damage to the structure and pose safety risks.

Send your message to us

EPDM Rubber Waterproof Membrane with Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords