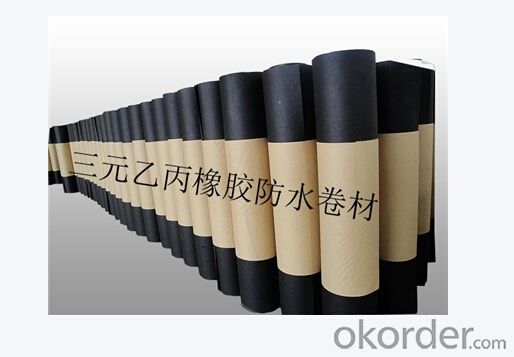

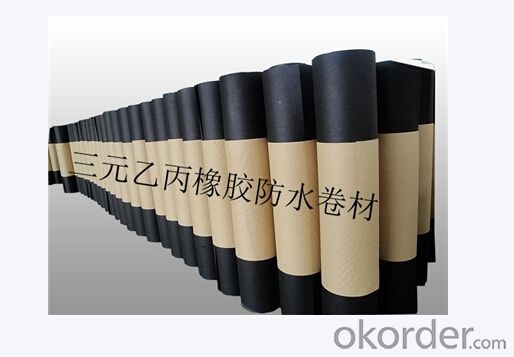

EPDM Waterproofing Rubber Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Dicription:

OKorder is offering high quality EPDM Rubber Waterproofing Membranes at great prices with worldwide shipping. Our supplier is a world-class manufacturer and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee a competitive price.

Product Applications:

OKorder's EPDM Rubber Waterproofing Membranes is ideal for roofs, basements, ponds, artificial lakes, steel structure roofs, swimming pools, subterranean construction, tunnels, etc.

Product Advantages:

OKorder's EPDM Rubber Waterproofing Membrane has been engineered with an extended service life to satisfy the demands of customers around the world.

Main Product Features:

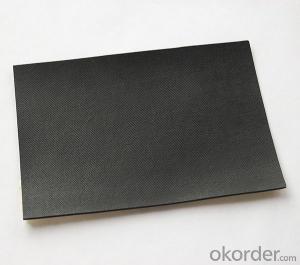

· Excellent environmental stress, crack, aging, and corrosion resistance

· Extended service life

· Lowest permeability

· High elongation

Product Specifications:

Name | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m (width) * 20m (length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced (homogeneous) | |||

Packing | 24 m² – 80m²/roll, with plastic bag | |||

Color | Black | |||

Number | Item | Unit | Value | |

1 | Size Variation | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Tensile Strength (Room Temperature) | Mpa | ≥7.5 | |

Tensile Strength (70°C) | Mpa | ≥2.3 | ||

3 | Elongation (Room Temperature) | % | ≥450 | |

Elongation (-20°C) | % | ≥200 | ||

4 | Tear Strength | KN/m | ≥25 | |

5 | Impermeability (30min) | * | 0.3Mpa no leakage | |

6 | Bending at Low Temperature | °C | ≤-40 | |

7 | Stretch Tension at Heat | Elongation | mm | ≤2 |

Shrinking | mm | ≤4 | ||

8 | Air Oven Aging (80°C x 168h) | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥70 | ||

9 | Anti-alkali | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥80 | ||

10 | During Manual Simulation | Retained Tensile Strength | % | ≥80 |

Retained Elongation | % | ≥70 | ||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is waterproofing?

A3: Waterproofing products are designed to “prevent” water penetration even under wet conditions such as hydrostatic pressure in the soil after heavy rain storms or spring thaws. Waterproofing membranes stretch as the foundation settles and bridge small hairline settlement cracks that can occur in the concrete or block.

Images:

- Q: Can a waterproofing membrane be used on roofs or only on vertical surfaces?

- A waterproofing membrane can be used on both roofs and vertical surfaces. It is a versatile solution that can effectively protect a variety of structures from water damage, including roofs, walls, and foundations.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to ensure that all necessary personal protective equipment (PPE) is used by the installation team. This may include gloves, safety glasses, and appropriate footwear to prevent any injuries or exposure to hazardous materials. Additionally, it is crucial to work in a well-ventilated area to avoid inhalation of fumes or vapors emitted during the installation process. If working in a confined space, proper measures should be taken to ensure adequate ventilation and the use of proper respiratory protection if necessary. Furthermore, it is important to follow the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This includes understanding any potential hazards associated with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to ensure that the installation area is properly prepared before beginning the process. This may involve removing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and first aid kits readily available in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to identify and address any potential safety risks promptly. By following these safety precautions, the installation of a waterproofing membrane can be carried out safely and effectively, minimizing the risk of accidents or injuries.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Yes, a waterproofing membrane can be used in conjunction with fire protection systems. While the primary function of a waterproofing membrane is to prevent water penetration, it can also act as a barrier to protect against fire. Some waterproofing membranes have fire-resistant properties, allowing them to withstand high temperatures and prevent the spread of fire. However, it is essential to ensure that the specific waterproofing membrane chosen is compatible and approved for use with the fire protection system in question.

- Q: Can a waterproofing membrane be used for potable water tanks?

- No, a waterproofing membrane cannot be used for potable water tanks. Potable water tanks require materials that are specifically designed and tested to ensure they are safe and non-toxic for drinking water storage.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. They are designed to protect against moisture and other environmental factors, including saltwater. The membranes are specifically engineered to provide a barrier that prevents water and salts from infiltrating and causing damage to underlying structures.

- Q: Can waterproofing membranes be used on concrete planters?

- Concrete planters can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to create a strong barrier against water, effectively preventing any water from penetrating the concrete and causing harm. By applying a waterproofing membrane to a concrete planter, it guarantees that the planter will remain completely watertight, thus avoiding any potential leaks or damage to the surrounding area. This is particularly advantageous for planters located indoors or in areas where water leakage could lead to structural harm or messy situations. Moreover, waterproofing membranes also provide an additional advantage by safeguarding the concrete against freeze-thaw cycles, which can ultimately result in cracks and deterioration over time. Overall, the utilization of waterproofing membranes on concrete planters enables an extended lifespan and the preservation of their functionality for an extended duration.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Yes, waterproofing membranes can be used on stormwater management systems. These membranes provide a protective barrier that prevents water from infiltrating into the system, ensuring efficient and reliable stormwater management.

- Q: Can a waterproofing membrane be used in historic buildings?

- Indeed, it is possible to utilize a waterproofing membrane in historic buildings. Given their age and construction materials, historic buildings frequently encounter challenges associated with moisture infiltration and water damage. To address this, waterproofing membranes offer a prevalent solution that prevents water seepage and safeguards the structural integrity of the building. Nonetheless, it is crucial to select a waterproofing membrane that is compatible with the materials and construction methods employed in the historic building to guarantee its preservation and adherence to historical authenticity. Moreover, any waterproofing work undertaken on a historic building should be carried out by professionals possessing expertise in historic preservation. This ensures proper installation and minimizes any adverse impact on the building's historical value.

- Q: Are waterproofing membranes resistant to thermal expansion?

- Yes, waterproofing membranes are typically resistant to thermal expansion. They are designed to withstand temperature changes without undergoing significant dimensional changes, ensuring their effectiveness in preventing water penetration and maintaining their integrity.

- Q: Can waterproof sheets be used on steel roof panels?

- to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials , As the engineering foundation and the building between the no leakage connection, is the entire project waterproof first barrier, the whole project plays a vital role.

Send your message to us

EPDM Waterproofing Rubber Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords