EPDM Rubber Waterproofing Membrane Leakage Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

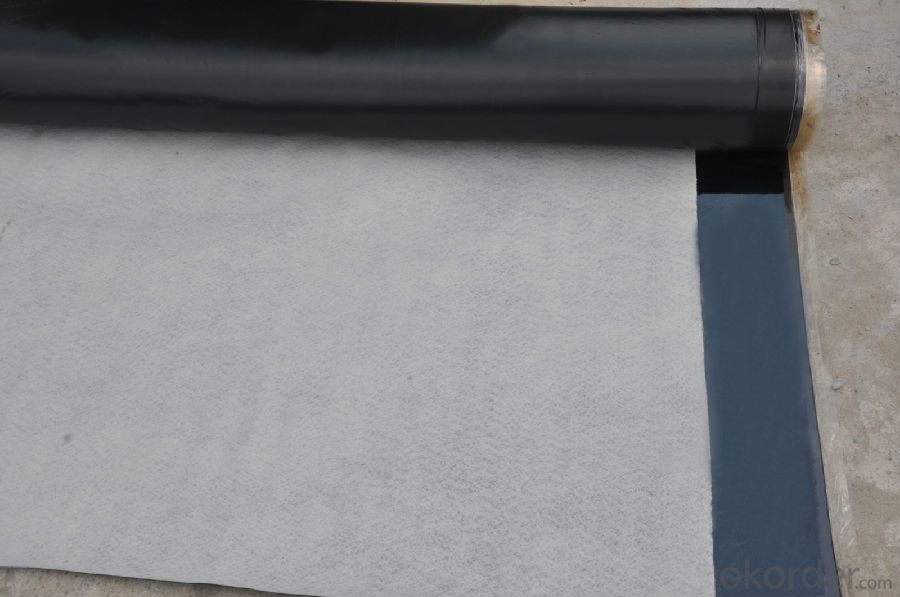

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Application of EPDM Waterproofing Membrane:

This product is suitable for all kinds of industrial and civil building roof, basement, reservoirs, ponds, sewage treatment system, civil air

defense projects, channel, girder factory waterproofing. Especially for highways, railways and culverts, bridges and other water impermeable

concrete bridge deck construction.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Many waterproofing membranes are designed to withstand a wide range of temperatures, from extremely hot to extremely cold. These membranes are made from materials that are resistant to cracking, melting, or becoming brittle in extreme temperatures. Additionally, some waterproofing membranes are specifically engineered for use in areas with extreme temperatures, such as those found in arctic or desert environments. It is important to choose a waterproofing membrane that is suitable for the specific temperature range of the area in which it will be used to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be installed in wet conditions?

- Yes, a waterproofing membrane can be installed in wet conditions. However, it is important to ensure that the surface being waterproofed is dry and free of any standing water before the installation. This is because the membrane needs a clean and dry surface to adhere properly and create an effective barrier against water. If the surface is wet, it may prevent the membrane from bonding correctly, leading to potential leaks or failures in the waterproofing system. Therefore, it is recommended to wait for the surface to dry or use appropriate methods to remove any excess moisture before installing the waterproofing membrane.

- Q: Can a waterproofing membrane be used for elevator shafts or equipment rooms?

- Elevator shafts and equipment rooms, being frequently exposed to moisture and water infiltration, can suffer significant damage to their equipment and structural components. Consequently, it becomes essential to implement a dependable waterproofing solution in order to prevent water penetration. One commonly employed method for safeguarding elevator shafts and equipment rooms against water damage is the use of a waterproofing membrane. This membrane, a thin layer of material, is applied to the surfaces of the shaft or room and functions as a barrier against water intrusion. Various materials like bitumen, PVC, or EPDM are typically utilized for these membranes due to their excellent waterproofing properties. To create a seamless and watertight enclosure, the waterproofing membrane is applied to all exposed surfaces, including walls, floors, and ceilings. Its purpose is to withstand hydrostatic pressure and prevent water from seeping into the elevator shaft or equipment room. Additionally, the membrane can also provide protection against other forms of moisture, such as condensation. Moreover, to enhance the effectiveness of the waterproofing membranes, they can be combined with other techniques like sealants and drainage systems. This multi-layered approach ensures a comprehensive waterproofing solution for elevator shafts and equipment rooms. In conclusion, a waterproofing membrane proves to be a suitable and reliable solution for protecting elevator shafts and equipment rooms from water infiltration. Its application creates a watertight enclosure, preventing potential damage to the equipment and structural components in these areas.

- Q: Can a waterproofing membrane be used on below-grade foundations?

- Yes, a waterproofing membrane can be used on below-grade foundations. In fact, it is recommended to use a waterproofing membrane on below-grade foundations to prevent water infiltration and protect the foundation from moisture damage. The membrane acts as a barrier, effectively preventing water from seeping into the foundation walls and causing issues such as leaks, mold, and structural damage. Additionally, waterproofing membranes are designed to withstand the high water pressure typically found in below-grade environments, making them an ideal solution for protecting foundations in basements and other below-ground structures.

- Q: Can waterproofing membranes be used on swimming pool decks?

- Swimming pool decks can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to act as a barrier against water infiltration, making them an excellent solution for areas that are constantly exposed to water, such as swimming pool decks. By applying a waterproofing membrane to the surface of the deck, it effectively prevents any water from seeping through and causing harm to the underlying structure. Moreover, waterproofing membranes also offer protection against chemicals, UV rays, and general wear and tear, which are commonly encountered in swimming pool environments. All in all, incorporating waterproofing membranes on swimming pool decks can extend their lifespan, decrease maintenance expenses, and elevate the overall safety and appearance of the space.

- Q: Does a waterproofing membrane require any specific cleaning or maintenance procedures?

- Yes, a waterproofing membrane does require specific cleaning and maintenance procedures. Regular cleaning of the membrane surface is necessary to remove any dirt, debris, or organic materials that may accumulate over time. It is recommended to use mild soap or detergent and a soft brush or sponge for cleaning. Additionally, periodic inspections should be conducted to check for any damage, cracks, or leaks in the membrane, which should be promptly repaired. Regular maintenance and proper care are crucial to ensure the long-term effectiveness and durability of the waterproofing membrane.

- Q: Can a waterproofing membrane improve energy efficiency?

- Yes, a waterproofing membrane can improve energy efficiency. By preventing water infiltration and moisture buildup, it helps to maintain the integrity of the building envelope, reducing the risk of air leaks and heat loss. This can result in improved insulation performance, reduced energy consumption for heating or cooling, and ultimately contribute to overall energy efficiency.

- Q: Can a waterproofing membrane be used on stucco surfaces?

- Indeed, stucco surfaces can benefit from the application of a waterproofing membrane. Due to its porous nature, stucco has the ability to absorb water. Thus, the utilization of a waterproofing membrane can effectively deter water infiltration and consequential damage. Acting as a barrier, the waterproofing membrane hinders water from permeating the stucco and compromising the underlying structure. Furthermore, it safeguards the stucco from moisture-related complications like cracking, mold, and mildew. It is imperative to select a waterproofing membrane specifically designed for stucco surfaces and adhere to the manufacturer's instructions for proper installation. Moreover, routine inspections and maintenance of the waterproofing membrane are highly recommended to ensure its efficacy and durability.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Plaster surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, plaster readily absorbs water, which can lead to damage caused by moisture. By applying a waterproofing membrane to plaster surfaces, a barrier is created to prevent water infiltration. This protective measure safeguards against problems like mold, mildew, and deterioration caused by moisture. Before applying the membrane, it is crucial to ensure the plaster surface is clean, dry, and devoid of loose or flaking material. It is also important to follow proper surface preparation and application techniques to guarantee the effectiveness and durability of the waterproofing system.

Send your message to us

EPDM Rubber Waterproofing Membrane Leakage Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords