EPDM Rubber Roofing Waterproof Membrane 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM Waterproof Membrane (Ethylene Propylene Diene Monomer) is a synthetic rubber, highly flexible stable material that is not only easy to work with, but long lasting and aquatic safe.

Property for EPDM Waterproof Membrane

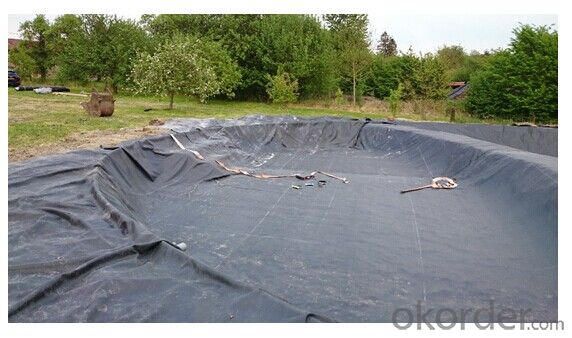

1)AQUATIC SAFE

A highly stable material that is formulated for safety when exposed to fish and plant life in a decorative pond

2)HIGHLY FLEXIBLE

Stays flexible in temperatures from -40° Fahrenheit to 175° Fahrenheit making it easy to install year round. Unlike other liner materials, it does not contain plasticizers that could make it become brittle with age and cause cracks or splits in the material, threatening aquatic life.

3)DESIGN VERSATILITY

EPDM's flexibility provides more versatility in the pond design. Unlike preformed liners, it can be easily shaped to fit the unique contours of the pond dimensions, allowing a more creative design

4)WEATHER RESISTANT

Remarkable resistance to the harmful effects of ultraviolet radiation (UV), ozone and other environmental conditions.

5)HIGH ELONGATION

High expansion and contraction characteristics that enable it to conform to objects in the sub grade. Should earth movement occur, rocks and tree roots could be dislodged beneath the liner, but EPDM's high elongation will enable it to stretch over such objects.

6)MINIMAL MAINTENANCE

Requires little or no regular maintenance once installed. However, if repair becomes necessary, it is easy to do without removing the liner from the pond with the EPDM repair patch.

Uses for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Data for EPDM Waterproof Membrane

Item | value | ||

JL1 | JF1 | ||

Tensile Strength (Mpa) | normal tamperature | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

Elongation at break (%) | normal tamperature ≥ | 450 | 450 |

-20°C ≥ | 200 | 200 | |

Tear Resistance (N) | ≥ | 25 | 18 |

Water impermeability | 30mm | 0.3Mpa | 0.3Mpa |

Cold bending | (°C) ≤ | -40 | -30 |

Heating Shrinking rate | extand << span=""> | 2 | 2 |

shrink << span=""> | 4 | 4 | |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a swimming pool deck coating?

- Indeed, a swimming pool deck coating can utilize a waterproofing membrane. Its purpose lies in preventing the infiltration of water and safeguarding the underlying surfaces. When applied with precision, a waterproofing membrane establishes an effective barrier against water and moisture, rendering it an excellent option for a swimming pool deck coating. This solution aids in averting water damage, such as cracking, spalling, or deterioration, while simultaneously providing an anti-slip surface to enhance safety. Moreover, a waterproofing membrane contributes to extending the lifespan of the pool deck by shielding it from water-related complications. In conclusion, opting for a waterproofing membrane as a swimming pool deck coating is a sensible and advantageous decision.

- Q: Can a waterproofing membrane be used in cold climates?

- Indeed, a waterproofing membrane is suitable for use in cold climates. It is highly advisable to utilize a waterproofing membrane in cold climates to safeguard structures from moisture damage caused by snow, ice, and freezing temperatures. These membranes are engineered to possess flexibility and durability, enabling them to endure extreme temperature fluctuations without experiencing cracks or deterioration. They establish a barrier that thwarts water from permeating the structure, a critical factor in cold climates where water can freeze and expand, resulting in substantial harm to buildings and infrastructure. Additionally, certain waterproofing membranes are specifically formulated to excel in cold weather conditions, offering heightened resistance to freeze-thaw cycles and ensuring long-term protection against water infiltration. Therefore, it is imperative to employ a high-quality waterproofing membrane in cold climates to uphold the integrity and longevity of structures.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Underground bunkers can utilize waterproofing membranes to great effect. Designed to establish a formidable defense against moisture, these membranes effectively thwart water infiltration into structures. This renders them an optimal solution for underground bunkers, which are susceptible to water encroachment due to their subterranean nature. By affixing a waterproofing membrane to the walls and floor of the bunker, it becomes possible to avert water seepage and maintain a dry interior. This is of paramount importance for safeguarding any stored items or occupants within the bunker. Moreover, waterproofing membranes offer additional advantages, such as insulation and protection against radon gas. It is crucial to select a membrane explicitly crafted for underground applications and capable of withstanding the unique conditions and pressures associated with subterranean environments.

- Q: Can a waterproofing membrane be used for a stadium roof?

- Yes, a waterproofing membrane can be used for a stadium roof. Waterproofing membranes are designed to provide a barrier against water infiltration and protect the underlying structure from moisture damage. Using a waterproofing membrane on a stadium roof can help prevent leaks and ensure the longevity of the roof.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. It is commonly used to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Indeed, a waterproofing membrane proves effective in chemical or hazardous surroundings. Its purpose is to serve as a barrier against water, moisture, and other liquids, including chemicals and hazardous substances. Typically, these membranes are constructed from chemical-resistant materials like polyurethane, PVC, or modified bitumen. This composition ensures their durability and ability to withstand exposure to various chemicals without harm. Nevertheless, it is vital to choose a waterproofing membrane specifically designed for chemical or hazardous environments to guarantee compliance with necessary requirements and standards. Moreover, proper installation and maintenance play a crucial role in ensuring the long-lasting effectiveness of the waterproofing membrane in such settings.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Yes, a waterproofing membrane does require special considerations for installation in high-humidity areas. High humidity can increase the moisture levels in the air, which can affect the performance and effectiveness of the membrane if not properly addressed during installation. Here are some important considerations: 1. Moisture control: In high-humidity areas, it is crucial to control the moisture levels before installing the waterproofing membrane. The surface should be thoroughly dried, and any existing moisture issues or leaks should be addressed and fixed before installation. 2. Vapor barriers: Installing a vapor barrier beneath the waterproofing membrane can help prevent moisture from penetrating through the membrane. This is especially important in high-humidity areas where the moisture levels in the air are consistently high. 3. Proper ventilation: Adequate ventilation is key in high-humidity areas to reduce moisture buildup. Make sure there is proper airflow and ventilation systems in place to promote drying and prevent condensation, which can compromise the integrity of the waterproofing membrane. 4. Waterproofing membrane selection: Not all waterproofing membranes are suitable for high-humidity areas. It is important to choose a membrane that is specifically designed and recommended for such environments. Look for membranes with high moisture resistance and durability. 5. Professional installation: Proper installation is essential for the long-term performance of the waterproofing membrane. In high-humidity areas, it is recommended to hire professional contractors who have experience working in similar conditions and can ensure proper installation techniques are followed. By considering these factors, you can ensure that the waterproofing membrane performs effectively and provides reliable protection against moisture in high-humidity areas.

- Q: Can a waterproofing membrane be used in showers and wet areas?

- Certainly, one can indeed utilize a waterproofing membrane in showers and areas prone to moisture. In actuality, it is highly advisable to incorporate a waterproofing membrane in these regions as a means of averting water harm and leaks. The waterproofing membrane functions as a barrier between the tile or flooring and the underlying floor, guaranteeing containment and channeling of any water that infiltrates the surface towards the drains. This ensures preservation of the foundational structure by preventing moisture-induced damage like decay or mold proliferation. Moreover, a waterproofing membrane also serves to mitigate the risk of water seepage into nearby spaces and inducing harm to adjacent walls or floors. It is of utmost importance to ensure accurate installation of the waterproofing membrane, diligently sealing all seams, corners, and penetrations to achieve the desired level of waterproofing.

- Q: Can a waterproofing membrane be used for a deck?

- Yes, a waterproofing membrane can be used for a deck. It provides an effective barrier against water and protects the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used on swimming pool decks?

- Indeed, swimming pool decks can benefit from the use of a waterproofing membrane. The purpose of these membranes is to effectively block water infiltration, which makes them particularly suitable for safeguarding areas that are constantly exposed to moisture, like swimming pool decks. Typically, these membranes are applied directly onto the deck's surface, creating an impermeable and long-lasting layer. This ensures that water does not permeate the deck, thus averting potential harm caused by dampness, such as cracks, the growth of mold, or structural decline. Furthermore, waterproofing membranes offer additional advantages, including prolonging the lifespan of the deck and enhancing its overall aesthetic appeal.

Send your message to us

EPDM Rubber Roofing Waterproof Membrane 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords