EPDM Rubber Roofing Waterproof Membrane with 1.0mm/1.2mm/1.5mm Height

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement

Main Features of EPDM Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good rooting penetration resistance

4. High puncture resistance

5. High tensile strength and good elongation, accommodating to structure movement

6 Easy installation, solid joint, and no environmental pollution

Specifications of EPDM Waterproof Membrane:

| Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

| Width | 2.05m,4m or others |

| Length | 20m |

| Model | EPDM, EPDM with fabric |

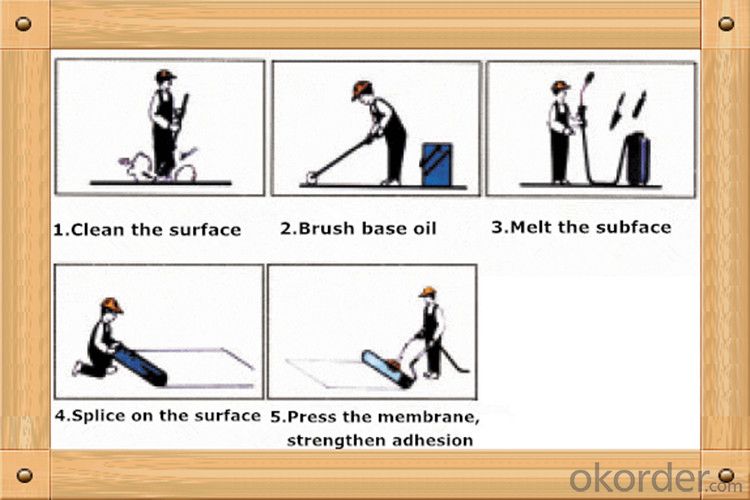

How to use it

Packaging & Shipping

1. EPDM rubber membrane packed in roll with pallet

2. The delivery time is 7-10 days after receive the deposit

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

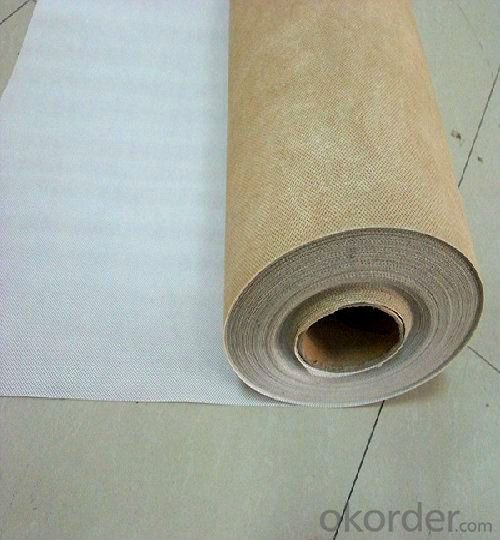

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in areas with high humidity?

- Yes, a waterproofing membrane can be used in areas with high humidity. In fact, high humidity can often contribute to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier that prevents water from seeping through surfaces, such as walls or floors. They can effectively protect against moisture and water infiltration, which is particularly important in high humidity areas where the risk of water damage is greater. By applying a waterproofing membrane, you can significantly reduce the likelihood of mold, mildew, and other moisture-related issues in these environments.

- Q: Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to handle the expansion and contraction that occurs due to temperature fluctuations, making them ideal for protecting structures from water damage caused by thermal stress.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Using both insulation materials and a waterproofing membrane together is often recommended in order to protect buildings from moisture and improve energy efficiency. The waterproofing membrane acts as a barrier against water infiltration, while the insulation materials help regulate temperature and minimize heat loss or gain. By combining these components, the building envelope can effectively shield against water damage and maintain a comfortable indoor environment. Proper installation and compatibility between the waterproofing membrane and insulation materials are crucial for achieving optimal performance and long-lasting results.

- Q: Can a waterproofing membrane be used in high-traffic areas?

- Yes, a waterproofing membrane can be used in high-traffic areas. Waterproofing membranes are designed to provide a protective barrier against moisture and water infiltration, making them suitable for use in areas that experience heavy foot traffic. These membranes are typically durable and resistant to wear and tear, ensuring their effectiveness and longevity even in high-traffic environments. Additionally, some waterproofing membranes are specifically designed for high-traffic areas and have additional features such as anti-slip properties to enhance safety. However, it is important to choose the right type of waterproofing membrane that is specifically designed for high-traffic areas to ensure maximum performance and durability. Consulting with a professional or a waterproofing expert can help determine the most suitable membrane for a specific high-traffic application.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Yes, a waterproofing membrane can be used on precast plastic surfaces. Waterproofing membranes are designed to create a barrier against moisture and can be applied to a variety of surfaces, including concrete, metal, and plastic. When properly installed, a waterproofing membrane can provide protection against water infiltration, ensuring the longevity and durability of the precast plastic surface. It is important to choose a waterproofing membrane that is compatible with plastic and follow the manufacturer's instructions for application to ensure proper adhesion and effectiveness.

- Q: Can a waterproofing membrane be used for a basement floor slab?

- Yes, a waterproofing membrane can be used for a basement floor slab. Waterproofing membranes are commonly used to prevent water infiltration and moisture issues in basements, including protecting the floor slab from water seepage. By installing a waterproofing membrane beneath the basement floor slab, it creates a barrier that prevents water from penetrating the concrete and causing damage. This helps keep the basement dry and free from moisture-related problems.

- Q: Are waterproofing membranes resistant to battery acid?

- Waterproofing membranes do not usually possess the necessary resistance against battery acid. Their main function is to create a barrier against water and moisture, and they are typically composed of materials like bitumen, rubber, or modified asphalt. Although these materials may exhibit some level of acid resistance, they are not typically engineered to endure the corrosive nature of battery acid. Battery acid, commonly sulfuric acid, can inflict substantial harm on various materials, including waterproofing membranes. If you are dealing with battery acid or find yourself in a situation where exposure to battery acid is a concern, it is advisable to employ materials specifically designed to withstand the corrosive effects of battery acid or seek professional assistance for appropriate solutions.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces of a structure. Waterproofing membranes are designed to create a barrier that prevents water or moisture from penetrating into the structure, whether it is applied on the inside or outside. On the interior, a waterproofing membrane can be used to protect basements, crawl spaces, or other areas prone to moisture intrusion. This helps to prevent water damage, mold growth, and other issues that can arise from excess moisture in these spaces. On the exterior, a waterproofing membrane is commonly used to protect the foundation, walls, and other structural elements from water infiltration. This is especially important in areas with heavy rainfall or where the water table is high. By applying a waterproofing membrane on the exterior, it helps to keep the structure dry and prevents potential damage caused by water seepage. It is important to note that different types of waterproofing membranes are available for specific applications, so the selection of the appropriate membrane will depend on the specific requirements of the project.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Precast stone block surfaces can benefit from the application of a waterproofing membrane. These membranes are frequently utilized to safeguard a variety of surfaces, including precast stone blocks, from water infiltration and moisture harm. The purpose of these membranes is to establish a barrier that prevents water from seeping into the surface and causing problems like mold, decay, or structural deterioration. By applying a waterproofing membrane to precast stone block surfaces, their durability and lifespan can be improved by shielding them from water-related difficulties. However, it is crucial to diligently adhere to the manufacturer's instructions and ensure that the chosen waterproofing membrane is appropriate for the specific type of precast stone block surface being treated.

- Q: Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. A waterproofing membrane is a barrier that is designed to prevent water from infiltrating or leaking through the structure it is applied to. This membrane is typically made of materials such as rubber, PVC, or bitumen, and is applied to surfaces such as concrete, stone, or masonry. In the case of a fountain waterproofing system, a waterproofing membrane can be applied to the interior surfaces of the fountain to prevent water from seeping through and causing damage. The membrane acts as a protective layer that ensures the water remains contained within the fountain, preventing leaks or seepage. It is important to select a waterproofing membrane that is specifically designed for fountains or water features. This type of membrane should be able to withstand constant exposure to water, as well as the specific conditions and chemicals that may be present in a fountain environment. Additionally, proper installation and maintenance are crucial to ensure the effectiveness of the waterproofing membrane. It is recommended to consult with a professional waterproofing contractor or fountain specialist to assess the specific requirements of your fountain and to determine the most suitable membrane and installation method. Overall, a waterproofing membrane can be an effective solution for ensuring the waterproofing of a fountain system, helping to maintain its structural integrity and prevent water-related damage.

Send your message to us

EPDM Rubber Roofing Waterproof Membrane with 1.0mm/1.2mm/1.5mm Height

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords