EPDM Roof Waterproof Membrane with 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

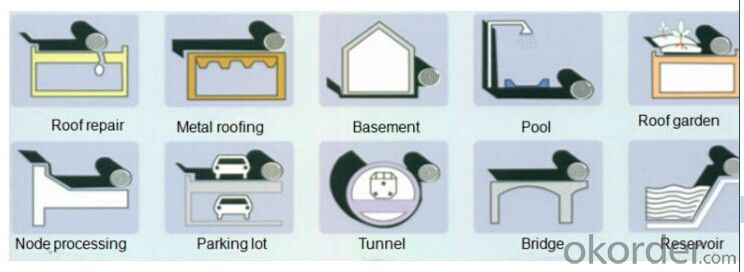

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for swimming pools or water features?

- Yes, a waterproofing membrane can be used for swimming pools or water features. Waterproofing membranes are specifically designed to prevent water leakage and are commonly used for various applications, including swimming pools and water features, to ensure they remain watertight and durable.

- Q: Can a waterproofing membrane be used in planter boxes or raised beds?

- Yes, a waterproofing membrane can be used in planter boxes or raised beds. It can help prevent water damage to the surrounding structures and extend the lifespan of the planter boxes or raised beds. However, it is important to ensure proper drainage to prevent water from pooling and causing root rot in the plants.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Tunnels and subway systems frequently encounter water infiltration as a result of the soil conditions or groundwater levels in their vicinity. To counteract this issue, a waterproofing membrane is commonly employed. This membrane serves as a protective shield, effectively obstructing water from permeating into the tunnels or subway systems. Its installation is typically carried out on the outer surfaces of the tunnel walls and roof, establishing an impervious seal. By doing so, it aids in the prevention of corrosion, decay, and harm to the structural components of the tunnels, guaranteeing the durability and safety of these subterranean infrastructures.

- Q: Can a waterproofing membrane be used on elevator shafts?

- Yes, a waterproofing membrane can be used on elevator shafts. Elevator shafts are vulnerable to water infiltration, and using a waterproofing membrane can help prevent water damage and leakage into the shaft.

- Q: Can a waterproofing membrane be used in areas with chemical exposure?

- Yes, a waterproofing membrane can be used in areas with chemical exposure. However, it is important to select a waterproofing membrane that is specifically designed to withstand chemical exposure. Not all waterproofing membranes are created equal, and some may not be suitable for use in areas with chemical exposure. Chemical-resistant waterproofing membranes are typically made from materials such as polyurethane, epoxy, or polyurea, which are known for their resistance to various chemicals. These membranes are designed to provide a protective barrier against moisture and chemicals, preventing them from seeping into the underlying surfaces. When choosing a waterproofing membrane for areas with chemical exposure, it is crucial to consider the specific chemicals that will be present. Different chemicals can have different effects on materials, so it is essential to select a membrane that is specifically designed to resist the chemicals in the environment. Consulting with a professional or manufacturer is recommended to ensure the appropriate selection of a chemical-resistant waterproofing membrane for the specific application.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Warehouses or storage facilities can utilize a waterproofing membrane. These membranes are specifically designed to safeguard structures against water damage by creating a barrier that prevents moisture infiltration. In warehouses and storage facilities, there are often large areas that are vulnerable to potential leaks or seepage, such as roofs, walls, and floors. By installing a waterproofing membrane, these structures can be effectively shielded from water intrusion, thereby preventing harm to stored goods and maintaining the facility's integrity. Waterproofing membranes come in various types, including bituminous, liquid-applied, or sheet membranes, providing flexibility in selecting the most appropriate option based on the specific requirements of the warehouse or storage facility. Furthermore, waterproofing membranes offer additional advantages such as thermal insulation and resistance to chemicals, further enhancing their value in ensuring the durability and functionality of warehouses or storage facilities.

- Q: About asphalt waterproofing membrane

- 4, SBS membrane is commonly referred to as a polymer modified asphalt coil, there are other APP, APAO and other modified asphalt membrane.

- Q: Can a waterproofing membrane be used in conjunction with flooring materials?

- Yes, a waterproofing membrane can be used in conjunction with flooring materials. In fact, it is often recommended to use a waterproofing membrane when installing certain types of flooring, such as in wet areas like bathrooms, kitchens, or basements. A waterproofing membrane acts as a barrier against moisture, preventing water from seeping through and damaging the flooring material or the subfloor. It helps to protect the flooring from leaks, spills, or even excessive moisture in the air. By using a waterproofing membrane, you can ensure the longevity and durability of your flooring, while also maintaining a waterproof and moisture-resistant environment.

- Q: How long does it take for a waterproofing membrane to dry?

- The drying time for a waterproofing membrane can vary depending on several factors such as the type of membrane, weather conditions, and application method. In general, it can take anywhere from a few hours to several days for a waterproofing membrane to fully dry. It is important to follow the manufacturer's instructions and consider the specific conditions of the project to determine an accurate drying time.

- Q: Can a waterproofing membrane be used for green roofs?

- Yes, a waterproofing membrane can be used for green roofs. In fact, it is a crucial component of the green roof system. A green roof consists of a layer of vegetation, growing medium, and a waterproofing membrane that prevents water from seeping into the building. The waterproofing membrane acts as a barrier to protect the structure underneath from water damage. It is designed to withstand the constant exposure to moisture and ensure that water does not penetrate through to the building. Additionally, the membrane helps to retain water within the green roof system, allowing for proper drainage and irrigation. Therefore, a high-quality waterproofing membrane is essential for the successful installation and functioning of a green roof.

Send your message to us

EPDM Roof Waterproof Membrane with 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords