Chinese Manufacturer Used In Roof PVC Waterproof Membrane In High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

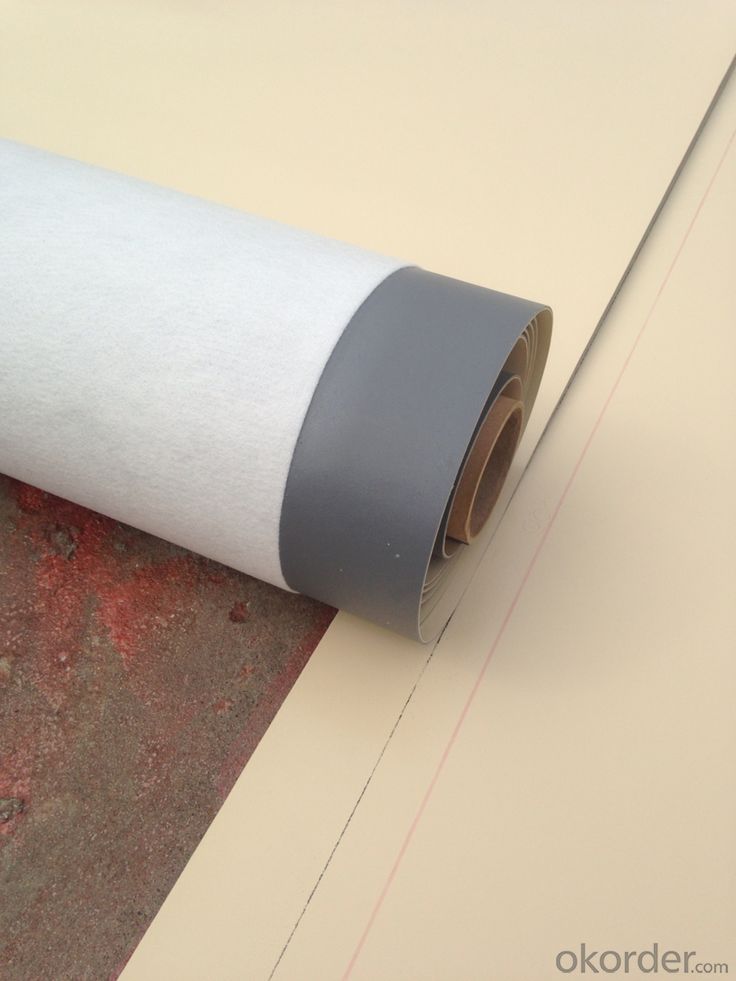

The PVC waterproofing rolls formulas are based upon polyvinyl chloride resin with other assistants added to provide flexibility and stability such as anti-oxidant,absorbent of ultraviolet light, plasticizer and plastic filling agent.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be repaired if damaged?

- If a waterproofing membrane gets damaged, it is possible to repair it. The repair method and whether it can be fixed on-site or by a professional will depend on the extent of the damage. Minor punctures or tears in the membrane can usually be patched using a sealant or adhesive. However, more significant or severe damage may necessitate the replacement of a section of the membrane. It is crucial to promptly address any damage in order to prevent additional water penetration and potential structural problems.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Can a waterproofing membrane be used for foundation repair?

- Yes, a waterproofing membrane can be used for foundation repair. Waterproofing membranes are commonly used to prevent water intrusion and can be applied to foundation walls to seal any existing cracks or gaps, preventing further damage or leaks. Additionally, they can help improve the overall strength and durability of the foundation, providing long-lasting protection against water damage.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

- Q: Can a waterproofing membrane be used for a swimming pool liner?

- Yes, a waterproofing membrane can be used as a swimming pool liner. Waterproofing membranes are designed to provide a barrier against water penetration, making them suitable for use in swimming pools to prevent leaks and maintain the water integrity.

- Q: Can a waterproofing membrane enhance the durability or lifespan of a structure?

- Certainly, the durability and lifespan of a structure can be significantly enhanced with the use of a waterproofing membrane. This type of membrane acts as a protective layer, applied to the exterior of structures like buildings or bridges, with the purpose of preventing water penetration. Essentially, it functions as a barrier that stops water from seeping into the structure and causing harm. Water is a common and destructive element that can negatively impact the longevity of any structure. When water infiltrates a building or any other type of structure, it can lead to a variety of problems, including mold growth, deterioration of building materials, corrosion of metal reinforcements, and even structural instability. However, by implementing a waterproofing membrane, these risks can be significantly reduced or even eliminated altogether. The installation of a waterproofing membrane not only prevents water from entering, but it also safeguards the structure against other environmental factors such as moisture, humidity, and freeze-thaw cycles. Acting as a shield, it ensures that the building materials remain intact and reduces the likelihood of cracks, leaks, and other forms of structural damage. By enhancing a structure's durability, a waterproofing membrane can effectively prolong its lifespan. Considered a long-term investment, it helps prevent costly repairs and maintenance caused by water-related issues. By keeping the structure dry and protected, it adds years or even decades to its lifespan, ultimately saving both time and money in the long run. In conclusion, a waterproofing membrane is an essential component for maintaining the durability and lifespan of any structure. By preventing water infiltration and protecting the building materials from damage, it ensures the longevity of the structure and provides peace of mind to its owners and occupants.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic or vehicle loadings. However, it is important to choose a membrane that is specifically designed for such applications to ensure durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Additionally, consideration should be given to the type of traffic or loading that the area will experience. For example, areas with vehicular traffic may require a membrane with higher compressive strength to withstand the weight of vehicles. In summary, while waterproofing membranes can be used in high-traffic or heavy loading areas, it is crucial to select the appropriate type of membrane that meets the specific demands of the application.

- Q: Can a waterproofing membrane be applied on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be applied on both interior and exterior surfaces of a structure.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces of a structure. Waterproofing membranes are designed to create a barrier that prevents water or moisture from penetrating into the structure, whether it is applied on the inside or outside. On the interior, a waterproofing membrane can be used to protect basements, crawl spaces, or other areas prone to moisture intrusion. This helps to prevent water damage, mold growth, and other issues that can arise from excess moisture in these spaces. On the exterior, a waterproofing membrane is commonly used to protect the foundation, walls, and other structural elements from water infiltration. This is especially important in areas with heavy rainfall or where the water table is high. By applying a waterproofing membrane on the exterior, it helps to keep the structure dry and prevents potential damage caused by water seepage. It is important to note that different types of waterproofing membranes are available for specific applications, so the selection of the appropriate membrane will depend on the specific requirements of the project.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. Waterproofing membranes are designed to provide a barrier against moisture and water infiltration, and this includes protection against saltwater. Saltwater can be highly corrosive and can cause damage to various materials, but waterproofing membranes are typically made from materials that are resistant to the corrosive effects of salt. These membranes are often composed of materials such as reinforced PVC, modified bitumen, or EPDM rubber, which have proven to be durable and reliable in saltwater environments. Additionally, waterproofing membranes are commonly used in applications such as basements, swimming pools, and marine structures, where they are exposed to saltwater regularly. Therefore, it can be concluded that waterproofing membranes are generally resistant to salt damage and can provide effective protection against saltwater infiltration.

Send your message to us

Chinese Manufacturer Used In Roof PVC Waterproof Membrane In High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords