EPDM Waterproof Membrane with 1.2mm-2.0mm Thickness/1.2m to 2.0m Width/20m Length

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM waterproofing Membrane

1. Introduction:

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material. Our EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications. Our EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

2. Product Features:

1).the excellent anti-aging, in the long term light, humidity, cold use of the natural

environment, small changes in physical properties, used in the temperature:

From -50 degree Celsius to +80degree Celsious.

2).with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion

of many chemical corrosive substances.

3).high tensile strength, high elongation, high flexibility, capable of sustaining

a puncture of hard material, good anti-crack, high adaptability of the grass roots'

contraction and the crack and deformation, and give full play to extend the performance.

4.long lifetime, high durability can achieve more than 25 years

5.the cold construction operation, no environment pollution and simple operation.

3. Technical Data:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

4. Specification:

Type | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

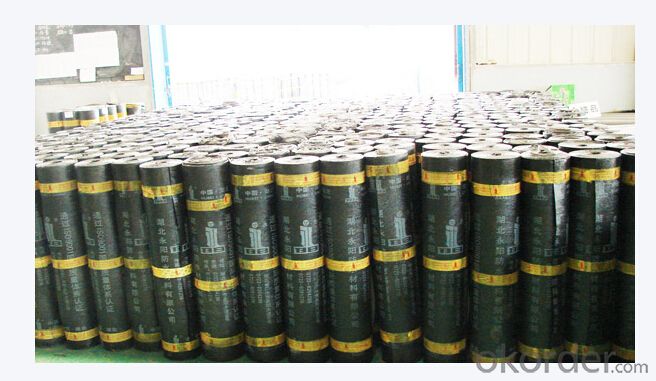

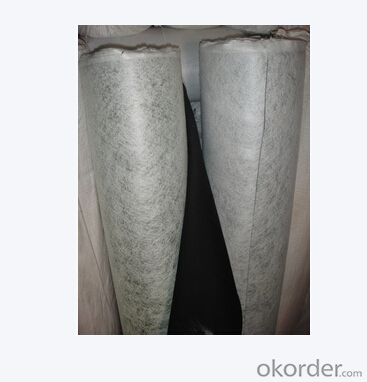

5. Some photos:

6.RFQ:

1) What's your payment terms?

T/T, L/C at sight is accepted

2) What's your package?

One roll with one woven bag, then several rolls in one pallet

3) What's your delivery time?

One week after advance payment received

- Q: Can waterproofing membranes be used on concrete pools?

- Yes, waterproofing membranes can be used on concrete pools. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied to various surfaces, including concrete. Concrete pools are susceptible to water leakage over time due to cracks or deterioration, and applying a waterproofing membrane can help prevent these issues. The membrane is typically applied to the pool's interior surface, creating a seamless and watertight seal. It is important to choose a high-quality waterproofing membrane specifically designed for use in swimming pools to ensure long-lasting and effective results.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction projects to prevent water infiltration and protect the building from water damage. The membrane is applied to surfaces such as walls, floors, and roofs, creating a barrier that prevents water from seeping through. In theaters and concert halls, where the protection of the building structure and equipment is crucial, waterproofing membranes can be highly beneficial. They can help prevent water damage to sensitive equipment, such as audiovisual systems, lighting fixtures, and musical instruments. Additionally, a waterproofing membrane can help maintain a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. Overall, using a waterproofing membrane in theaters or concert halls can help ensure the longevity and functionality of the building while providing a safe and enjoyable experience for everyone involved.

- Q: Can a waterproofing membrane be used on concrete tanks?

- Concrete tanks can indeed benefit from the use of a waterproofing membrane. The primary purpose of this membrane is to create a barrier that prevents water from penetrating through. It is specifically designed to be applied on various surfaces, including concrete. Waterproofing membranes are especially useful for concrete tanks that are used for water storage or containment. By applying the membrane on the concrete surface, a protective layer is formed that effectively stops water from entering or exiting the tank. This is crucial for maintaining the tank's structural integrity and avoiding any potential damage or contamination caused by water leakage. Furthermore, these membranes also offer protection against other substances that may be present in the tank, such as chemicals or pollutants. It is important to choose the right type of membrane that suits the specific requirements of the concrete tank. Following the manufacturer's instructions for application is also essential to ensure that the waterproofing is effective and long-lasting.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Indeed, rooftops with gardens can benefit greatly from the utilization of a waterproofing membrane. Employing a waterproofing membrane is strongly advised as it shields the foundational framework from harm caused by water. Given that a rooftop garden contributes additional weight and moisture to the roof, it is imperative to have a reliable waterproofing system in place to avert leaks and guarantee the roof's durability. The waterproofing membrane serves as a safeguard against water infiltration, effectively maintaining dry conditions for both the rooftop garden and the underlying structure.

- Q: Can a waterproofing membrane be applied to existing structures?

- Yes, a waterproofing membrane can be applied to existing structures. The application of a waterproofing membrane is a common and effective method used to prevent water infiltration and damage to buildings. Whether it is a concrete structure, a roof, or a basement, waterproofing membranes can be installed on the exterior or interior surfaces to create a barrier against water penetration. There are different types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, and spray-applied membranes, which can be chosen based on the specific requirements of the structure. The process of applying a waterproofing membrane to an existing structure typically involves thorough surface preparation, including cleaning, repairing any existing cracks or damages, and ensuring a smooth and even surface. Once the surface is prepared, the membrane is applied using the recommended method, ensuring proper adhesion and coverage. Waterproofing membranes are designed to withstand environmental factors, such as UV rays, temperature fluctuations, and water pressure, providing long-lasting protection to existing structures. However, it is important to consult with a professional waterproofing contractor to assess the condition of the structure and determine the most appropriate and effective waterproofing solution.

- Q: Does a waterproofing membrane require any special maintenance?

- Yes, a waterproofing membrane does require some special maintenance. While it is designed to be durable and withstand various weather conditions, regular maintenance is necessary to ensure its effectiveness and longevity. Some maintenance tasks include: 1. Regular inspections: Check the membrane for any signs of damage, such as cracks, tears, or punctures. Inspect the seams and edges to ensure they are properly sealed. 2. Clean the surface: Remove any debris, dirt, or vegetation that may have accumulated on the membrane. This can be done using a broom, brush, or pressure washer (if recommended by the manufacturer). 3. Clear drains and gutters: Ensure that the drains and gutters connected to the membrane are not clogged or blocked. This will prevent water from pooling on the surface and potentially causing damage. 4. Repair any damages: If any cracks, tears, or punctures are found, they should be repaired promptly to prevent water leakage. Follow the manufacturer's instructions for the appropriate repair method and materials. 5. Regularly check the waterproofing system: If the membrane is part of a larger waterproofing system, such as a basement or roof, it is important to inspect and maintain the entire system. This may involve checking the integrity of other components, such as drainage pipes or flashing. 6. Consider professional maintenance: Depending on the size and complexity of the waterproofing system, it may be beneficial to hire a professional maintenance service. They can conduct thorough inspections, perform necessary repairs, and provide expert advice on maintaining the membrane. By following these maintenance practices, you can ensure that your waterproofing membrane remains in good condition and effectively protects your structure from water damage.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits to prevent water infiltration and protect the structure from potential damage caused by moisture.

- Q: Is the foundation pit waterproofing and the foundation pouring on the working face?

- The current project is generally not in the bottom of the foundation to do the membrane waterproof, and generally will be changed into fine stone concrete or cement mortar to do rigid waterproof, in the base side and the basement wall to do the membrane waterproof, the base of the waterproof before the banding reinforcement, Basic side and basement wall waterproofing after basement wall construction is done

- Q: Can a waterproofing membrane be used in shower pans?

- Yes, a waterproofing membrane can be used in shower pans. In fact, it is highly recommended to use a waterproofing membrane in shower pans to prevent water leakage and damage to the underlying structure.

- Q: Are waterproofing membranes resistant to ponding water?

- Yes, waterproofing membranes are designed to be resistant to ponding water. These membranes create a barrier that prevents water from seeping through and causing damage to the underlying structure.

Send your message to us

EPDM Waterproof Membrane with 1.2mm-2.0mm Thickness/1.2m to 2.0m Width/20m Length

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords