Vulcanized EPDM Waterproof Membrane Width1.2m Thickness 1.2mm, 1.5mm, 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

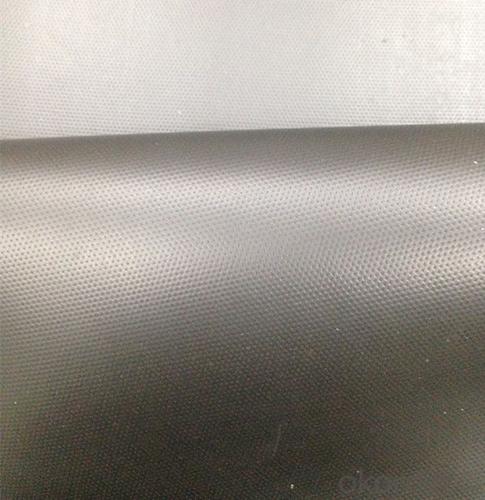

Photos:

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Many waterproofing membranes are designed to withstand a wide range of temperatures, from extremely hot to extremely cold. These membranes are made from materials that are resistant to cracking, melting, or becoming brittle in extreme temperatures. Additionally, some waterproofing membranes are specifically engineered for use in areas with extreme temperatures, such as those found in arctic or desert environments. It is important to choose a waterproofing membrane that is suitable for the specific temperature range of the area in which it will be used to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to protect the structure from water damage. They are specifically designed to create a barrier against water infiltration, preventing leaks and moisture buildup. By applying a waterproofing membrane to the building's exterior, it helps to ensure the longevity and durability of the structure. Shopping malls and commercial buildings often have large surface areas that are exposed to different weather conditions, making them susceptible to water damage. Therefore, using a waterproofing membrane is an effective solution to protect these buildings and maintain their structural integrity.

- Q: Can a waterproofing membrane be used on flat roofs?

- Yes, a waterproofing membrane can be used on flat roofs. In fact, it is a common and effective method used to protect flat roofs from water damage and leakage. The waterproofing membrane is designed to provide a durable and watertight barrier, ensuring the roof remains protected from rain, snow, and other elements.

- Q: Elastomer modified asphalt waterproofing membrane for what purpose? Need to pay attention to a few things?

- First, the quality of waterproof base surface Waterproof base (leveling layer) must be hard, smooth, dry, clean, should not have anti-sand, remove the sharp objects. Waterproof base surface if there are defects, should be done before the waterproof repair, must be painted base treatment agent. Waterproof surface should not have ice, snow or water.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Waterproofing membranes typically do not possess resistance against sulfuric acid exposure. Sulfuric acid, being an immensely corrosive substance, has the potential to inflict substantial harm to various materials, including waterproofing membranes. The membrane's deterioration can occur as a result of sulfuric acid's highly acidic properties, ultimately causing its failure. Hence, if there exists a chance of sulfuric acid exposure, it becomes crucial to employ materials that are explicitly engineered to endure such corrosive substances.

- Q: Can a waterproofing membrane be used for a warehouse?

- Certainly, a warehouse can utilize a waterproofing membrane. This particular product is specifically designed to prevent the infiltration of water and safeguard structures from moisture-related harm. It can be applied to various surfaces, including concrete, metal, and wood, thereby making it suitable for warehouses constructed from diverse materials. By implementing a waterproofing membrane in a warehouse, several advantages can be obtained. Primarily, it aids in the prevention of water infiltration, which is especially vital in regions with heavy precipitation or in close proximity to bodies of water. By obstructing water from permeating the warehouse, it serves as a safeguard for the contents within, shielding them from water-induced damage such as rust, mold, and decay. Furthermore, a waterproofing membrane can enhance the overall structural integrity of the warehouse. Moisture has the potential to weaken the construction materials employed, leading to potential structural problems over time. By establishing a barrier against water, a waterproofing membrane can significantly prolong the lifespan of the warehouse and minimize the necessity for costly repairs. Moreover, a waterproofing membrane can also contribute to a healthier indoor environment within the warehouse. By thwarting water infiltration, it diminishes the risk of mold growth, which can be detrimental to air quality and the well-being of occupants. This is especially crucial if the warehouse stores delicate goods or if workers spend substantial amounts of time within the facility. To summarize, a warehouse can indeed incorporate a waterproofing membrane. It provides protection against water infiltration, enhances structural integrity, and contributes to a healthier indoor environment. The selection of an appropriate waterproofing membrane and ensuring its proper installation are critical in guaranteeing optimal performance and long-lasting protection for the warehouse.

- Q: Can waterproofing membranes be used on parking decks?

- Indeed, parking decks can benefit from the application of waterproofing membranes. Given their exposure to diverse weather conditions and constant vehicular movement, water infiltration and subsequent damage are potential concerns. To combat this, waterproofing membranes act as a safeguard, effectively blocking water from seeping into the structure and causing deterioration. These membranes are engineered to withstand significant loads and resist the harmful effects of automotive fluids, making them an optimal choice for parking decks. By implementing waterproofing membranes, the lifespan of the parking deck can be prolonged, minimizing the necessity for expensive repairs and guaranteeing the safety and integrity of the structure.

- Q: Can a waterproofing membrane be used on tunnels with vehicular traffic?

- Tunnels with vehicular traffic can benefit from the application of a waterproofing membrane. These membranes are designed to act as a barrier against water infiltration, safeguarding the structure from potential damage caused by moisture. In the presence of vehicular traffic, water can seep through the concrete, leading to corrosion, deterioration, and even compromising the tunnel's structural integrity. By utilizing a waterproofing membrane, a protective layer is created, preventing water from penetrating the tunnel's walls, roof, and floor. This protective measure not only prolongs the lifespan of the tunnel but also guarantees the safety of vehicles passing through. However, it is crucial to carefully choose a waterproofing membrane specifically engineered to withstand heavy traffic conditions, successfully enduring the constant load and wear. Moreover, proper installation and regular maintenance play a vital role in ensuring the effectiveness and longevity of the waterproofing system in tunnels with vehicular traffic.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. Historic buildings often face challenges related to moisture infiltration and water damage due to their age and construction materials. Waterproofing membranes are a common solution to prevent water seepage and protect the building's structural integrity. However, it is important to choose a waterproofing membrane that is compatible with the historic building's materials and construction methods to ensure its preservation and adherence to historical authenticity. Additionally, any waterproofing work done on a historic building should be carried out by professionals with expertise in historic preservation to ensure proper installation and minimal impact on the building's historical value.

- Q: Can a waterproofing membrane be applied in cold weather conditions?

- Applying a waterproofing membrane in cold weather is possible, but the temperature range may differ depending on the product and manufacturer guidelines. Certain membranes can endure cold temperatures and be applied as low as -20 degrees Celsius (-4 degrees Fahrenheit), while others may have a higher minimum application temperature. Following the manufacturer's instructions is crucial, as well as ensuring the surface is adequately prepared and free from ice, snow, or moisture. Consulting with an experienced professional contractor who has worked with waterproofing membranes in cold weather conditions is also recommended for optimal results.

Send your message to us

Vulcanized EPDM Waterproof Membrane Width1.2m Thickness 1.2mm, 1.5mm, 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords