High Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs, basements, toilets etc; and the waterproofing of bridges, parking area, tunnels, reservoir etc.

Characteristic of Self-adhesive Waterproofing Membrane:

1)Self-adhesion without bonding agent,torching.

2)Good rubber elasticity,and elongation

3)Excellent adhension bond

4)Good self-coalescence

5)Safe application,no pullution

6)Excellent waterproof and high strength

7)Available for wet ground

8)Corrosion resistance and ageing-resistance

Description of Self-adhesive Waterproofing Membrane:

Description Details | Width | Length | Thickness | Weight | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials (PE) | 1m | 10m | 2mm | 28kg/roll | |

| 1m | 10m | 3mm | 41kg/roll | |

| 1m | 8m | 4mm | 45kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with mineral granules(M)

| 1m | 10m | 3mm | 45kg/roll | |

| 1m | 8m | 4mm | 47kg/roll | |

| 1m | 8m | 5mm | 57kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with aluminum foil(Al) | 1m | 10m | 2mm | 29kg/roll | |

| 1m | 10m | 3mm | 42kg/roll | |

| 1m | 8m | 4mm | 46kg/roll | |

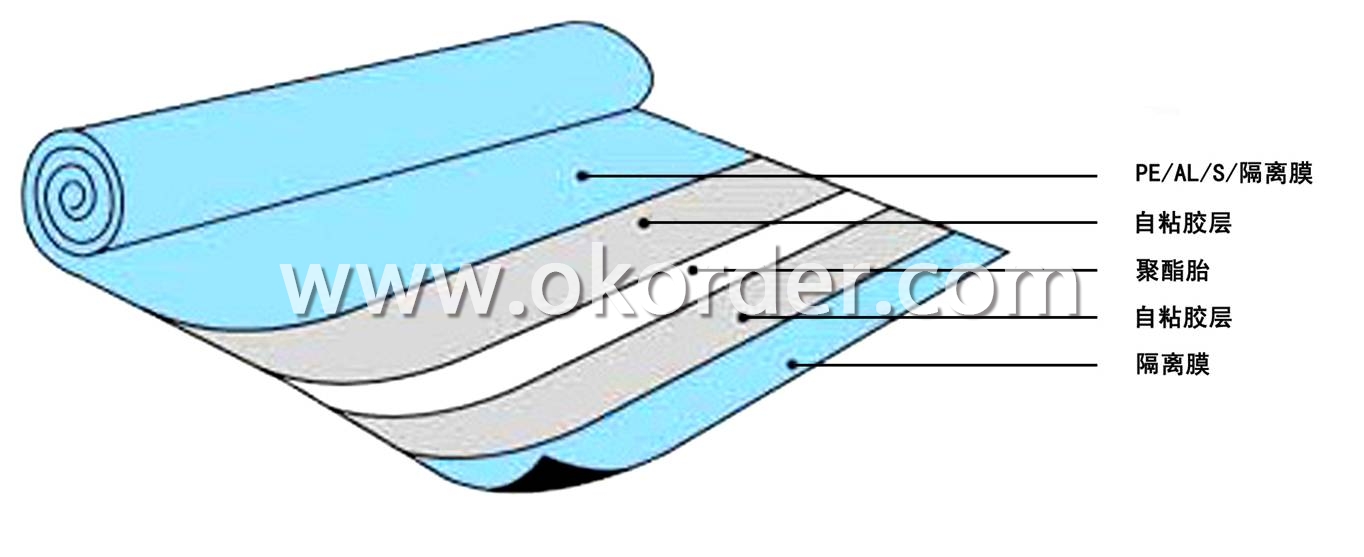

Pictures of Self-adhesive Waterproofing Membrane:

- Q: Can a waterproofing membrane be used for above-grade applications?

- Indeed, above-grade applications can benefit from the use of a waterproofing membrane. In construction, waterproofing membranes are widely employed to safeguard structures against water infiltration and subsequent harm. While they are commonly utilized for below-grade purposes like basements and foundations, waterproofing membranes can also be applied above-grade on surfaces such as roofs, decks, and exterior walls. When utilized above-grade, waterproofing membranes serve as an effective moisture barrier, preventing water from permeating the structure. These membranes are specifically designed to endure prolonged exposure to various elements, including rain, snow, and UV rays. By effectively sealing the surface, a waterproofing membrane aids in shielding the structure from water damage, mold growth, and deterioration. Several types of waterproofing membranes are available for above-grade applications, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are typically constructed from materials such as modified bitumen, polyurethane, or rubberized asphalt, which possess exceptional waterproofing properties. Proper surface preparation is crucial when installing a waterproofing membrane above-grade. The surface must be thoroughly cleansed, completely dry, and devoid of any substances that might undermine the membrane's adhesion. Additionally, it is vital to adhere to the manufacturer's instructions and guidelines regarding application techniques and recommended thickness. In conclusion, a waterproofing membrane can effectively shield structures from water infiltration and damage when used in above-grade applications. By selecting the appropriate membrane type and adhering to proper installation procedures, a durable and dependable waterproofing system can be established for above-grade surfaces.

- Q: Can waterproofing membranes be used on utility manholes?

- Yes, waterproofing membranes can be used on utility manholes. Waterproofing membranes are specifically designed to provide a barrier against water infiltration, making them suitable for use in areas where water is present, such as manholes. These membranes are typically applied to the walls and floors of the manhole to prevent water from seeping through and causing damage to the structure or the utilities within. By effectively sealing off the manhole, waterproofing membranes help to maintain the integrity and functionality of the utilities and prevent water-related issues such as corrosion, leaks, and the degradation of materials. Additionally, waterproofing membranes can also provide protection against other elements such as chemicals, gases, and soil contaminants that may be present in or around the manhole. Therefore, using waterproofing membranes on utility manholes is a common practice to ensure their long-term durability and functionality.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration, regardless of whether it is applied to the inside or outside of a structure.

- Q: Can a waterproofing membrane prevent leaks from occurring?

- Preventing leaks is indeed possible with the use of a waterproofing membrane. This membrane is a thin material layer that, when applied to a surface, renders it completely impervious to water. Its purpose is to serve as a barrier, effectively stopping water from seeping through and causing any leaks. With correct installation and ongoing maintenance, a waterproofing membrane can provide reliable protection against water damage for a variety of structures, such as roofs, basements, bathrooms, and foundations. It is specifically designed to withstand the forces of nature, including rain, snow, and moisture, thus greatly reducing the likelihood of leaks and water infiltration. However, it is worth noting that the efficacy of a waterproofing membrane also relies on the quality of the product, proper installation procedures, and regular maintenance.

- Q: Can a waterproofing membrane be used in kitchens?

- Certainly! Kitchens can indeed benefit from the application of a waterproofing membrane. It is strongly advised to employ such membranes in spaces that are susceptible to moisture and water, like kitchens. These specialized membranes are engineered to establish a shield against water, thwarting its infiltration into the foundation and safeguarding it against harm. They are frequently utilized on floors, walls, and even countertops to ensure a tight seal that resists water damage, the growth of mold, and various other complications. Moreover, waterproofing membranes can aid in soundproofing while enhancing the sturdiness and lifespan of kitchen surfaces.

- Q: Is the foundation pit waterproofing and the foundation pouring on the working face?

- The current project is generally not in the bottom of the foundation to do the membrane waterproof, and generally will be changed into fine stone concrete or cement mortar to do rigid waterproof, in the base side and the basement wall to do the membrane waterproof, the base of the waterproof before the banding reinforcement, Basic side and basement wall waterproofing after basement wall construction is done

- Q: What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- PET refers to polyethylene terephthalate, PET film using polyester composite film as the surface material, coated with rubber asphalt adhesive material, with cement mortar paste or self-adhesive. Can be constructed on the wet base surface, the grass-roots requirements are low, with high bond strength, bonding effect is good, not channeling water and so on.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose particles or contaminants. Proper surface preparation is crucial to allow for proper adhesion of the membrane. Secondly, it is essential to choose a suitable waterproofing membrane that is specifically designed for use on concrete surfaces, as different materials may have different compatibility and performance characteristics. Additionally, the correct application technique and thickness of the membrane should be followed as per the manufacturer's instructions. Finally, it is important to consider factors such as expansion joints, cracks, and structural movement, as these can affect the overall effectiveness and durability of the waterproofing system.

- Q: Can a waterproofing membrane be used for below-grade parking garages?

- Yes, a waterproofing membrane can be used for below-grade parking garages. Waterproofing membranes are commonly used in construction projects to prevent the ingress of water into the structure. In below-grade parking garages, where the structure is below ground level, the risk of water infiltration is higher. Therefore, using a waterproofing membrane is an effective solution to protect the parking garage from water damage and ensure its durability.

- Q: Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Europe; North America; Africa; Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6- 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100000 Square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

High Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords