Concrete Foundation Waterproofing Membrane

Concrete Foundation Waterproofing Membrane Related Searches

Waterproofing Concrete Floors Waterproofing Concrete Block Walls Concrete Slab Waterproofing Waterproof Concrete Blocks Geomembrane Waterproofing Bentonite Waterproofing Membrane Waterproof Admixture Concrete Waterproof Geomembrane Waterproof Membrane For Decks Exterior Foundation Waterproofing Materials Paintable Waterproof Membrane Mapei Waterproofing Membrane Red Guard Waterproofing Membrane Redgard Waterproofing Membrane Waterproofing Membrane Philippines Residential Waterproofing Damp Proof Membrane Waterproofing Geomembrane Liner Concrete Resurfacing Waterproofing Wet Areas Bitumen Roofing Membrane Commercial Waterproofing Waterproofing Homes Waterproofing Additive For Cement Render Waterproof Material Aquaseal Basement Waterproofing Forming Concrete Waterproof Cement Board Shower Dimpled Foundation Membrane Concrete RepellentConcrete Foundation Waterproofing Membrane Supplier & Manufacturer from China

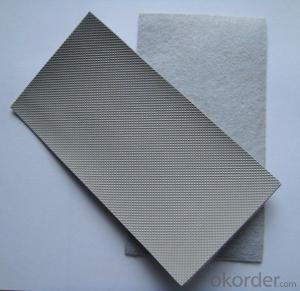

Concrete Foundation Waterproofing Membrane is a specialized product designed to protect and preserve the structural integrity of concrete foundations. This membrane is engineered to prevent water penetration, which can lead to costly damage and deterioration over time. By providing a robust barrier against moisture, the Concrete Foundation Waterproofing Membrane ensures that the foundation remains dry and stable, extending its lifespan and maintaining the structural safety of the building.The Concrete Foundation Waterproofing Membrane is widely used in various construction projects, particularly in scenarios where water resistance is crucial. It is commonly applied to both residential and commercial buildings, as well as in civil engineering projects such as bridges, tunnels, and dams. This product is also suitable for use in areas with high water tables or in regions prone to flooding, making it an essential component in the construction of resilient infrastructure.

Okorder.com is a leading wholesale supplier of Concrete Foundation Waterproofing Membrane, offering a vast inventory to meet the diverse needs of contractors and construction companies. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Concrete Foundation Waterproofing Membrane they provide is of the highest standard, helping to safeguard structures against the damaging effects of water infiltration.

Hot Products