PVC Waterproofing Plastic Membrane for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

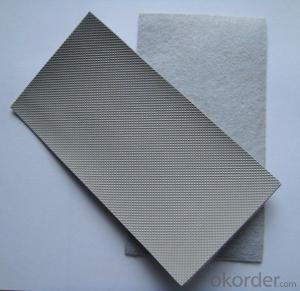

Product Description of PVC Waterproofing Plastic Membrane for Construction:

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope of PVC Waterproofing Plastic Membrane for Construction:

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering.

Product Category of PVC Waterproofing Plastic Membrane for Construction:

Single composite PVC waterproof materials

Double composite PVC waterproof board

Seperate PVC waterproof board

Some sticky type PVC waterproof materials

Technical Parameters of PVC Waterproofing Plastic Membrane for Construction:

No. | Item | Index | |||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10.0 | - | - | 10.0 | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Yes, a waterproofing membrane can be used in conjunction with soundproofing materials. In fact, it is quite common to use both of these materials together in construction projects. Waterproofing membranes are typically used to prevent the penetration of water into a structure, while soundproofing materials are used to reduce noise transmission. These two materials serve different purposes but can be used simultaneously to provide both waterproofing and soundproofing benefits. For example, in a building with a basement or a bathroom, a waterproofing membrane can be installed on the walls or floors to prevent water infiltration, and then soundproofing materials can be added on top of the membrane to reduce noise transmission from adjacent areas. By combining these two materials, a building can be protected from water damage while also providing a quieter and more comfortable environment for its occupants.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- Yes, a waterproofing membrane can be used in conjunction with expansion joint systems. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. Expansion joint systems, on the other hand, are installed to allow for movement and accommodate thermal expansion and contraction in structures. By combining the use of a waterproofing membrane and expansion joint systems, it is possible to provide both waterproofing and movement accommodation in a structure. This ensures that the structure remains protected from water damage while allowing for necessary movement. It is important to properly design and install both the waterproofing membrane and the expansion joint system to ensure their compatibility and effectiveness.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. The membrane will provide a protective barrier against water penetration, helping to prevent moisture damage and corrosion on the nickel surface.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Indeed, adobe block surfaces can be treated with a waterproofing membrane. These blocks, composed of a blend of clay, sand, and straw, are prone to water damage. By applying a waterproofing membrane, the infiltration of water can be prevented, thus safeguarding the adobe blocks against various moisture-related problems like cracking, erosion, or mold formation. It is essential to verify that the waterproofing membrane is suitable for adobe surfaces and adhere to the manufacturer's instructions for application. Furthermore, prior to applying the membrane, it is vital to adequately prepare the surface and address any preexisting damages to ensure optimal performance.

- Q: Can a waterproofing membrane be used on lead surfaces?

- Yes, a waterproofing membrane can be used on lead surfaces. Lead surfaces are often found in the roofing industry, and applying a waterproofing membrane can help protect against water damage and leaks. It is important to ensure that the waterproofing membrane is compatible with lead, as some membranes may react with or degrade the lead material. Additionally, proper surface preparation and installation techniques should be followed to ensure a secure and effective waterproofing solution. Consulting with a professional or manufacturer for specific product recommendations and installation guidelines is recommended.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Can a waterproofing membrane be used on brick block surfaces?

- Brick block surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are widely used to create a barrier against water infiltration and safeguard buildings from moisture damage. When applied correctly, they effectively seal brick block surfaces, safeguarding against water penetration and promoting the structure's longevity and durability. Acting as a protective layer, the membrane prevents water from seeping into the bricks and causing issues like deterioration, cracking, or mold growth. It is crucial to choose a waterproofing membrane specifically designed for brick block surfaces and meticulously follow the manufacturer's instructions for proper application. Moreover, seeking guidance from a professional contractor experienced in waterproofing is highly recommended to ensure optimal outcomes and long-term performance.

- Q: Does a waterproofing membrane require a topcoat or sealer?

- Yes, a waterproofing membrane typically requires a topcoat or sealer in order to provide additional protection and enhance its effectiveness. While the membrane itself is designed to prevent water penetration, applying a topcoat or sealer can further reinforce its waterproofing capabilities and extend its lifespan. The topcoat or sealer acts as an extra layer of defense against moisture, UV rays, and other potential sources of damage. Additionally, it can help seal any small cracks or imperfections in the membrane, ensuring a tighter seal and reducing the risk of water infiltration. Therefore, while a waterproofing membrane can offer some level of protection on its own, the addition of a topcoat or sealer is generally recommended for optimal performance and longevity.

- Q: Are waterproofing membranes suitable for historical preservation projects?

- Waterproofing membranes can be suitable for historical preservation projects, depending on the specific circumstances and goals of the project. Waterproofing membranes are designed to provide a protective barrier against water infiltration, which can help to prevent damage to historical structures caused by moisture. In some cases, historical buildings may have existing waterproofing systems that are deteriorated or no longer effective. In these situations, the use of modern waterproofing membranes can be a viable option to protect and preserve the structure. These membranes can be installed discreetly, without altering the original appearance or architectural integrity of the building. However, it is crucial to approach the use of waterproofing membranes in historical preservation projects with caution. The potential impact on the authenticity and historical value of the structure must be carefully evaluated. Some historical buildings may have unique construction methods or materials that require specialized preservation techniques. In such cases, alternative preservation methods that do not involve the use of membranes may be more appropriate. Additionally, it is important to consider the long-term consequences and maintenance requirements of waterproofing membranes. Some membranes may have a limited lifespan, and periodic inspections and maintenance may be necessary to ensure their continued effectiveness. This ongoing maintenance should be factored into the overall preservation plan and budget. Ultimately, the decision to use waterproofing membranes in historical preservation projects should be based on a thorough assessment of the specific needs and characteristics of the building, as well as the preservation objectives. Consulting with preservation experts, architects, and engineers can help to determine the most suitable approach for each unique project.

Send your message to us

PVC Waterproofing Plastic Membrane for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords