Heat-resistant Polyvinyl Chloride PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

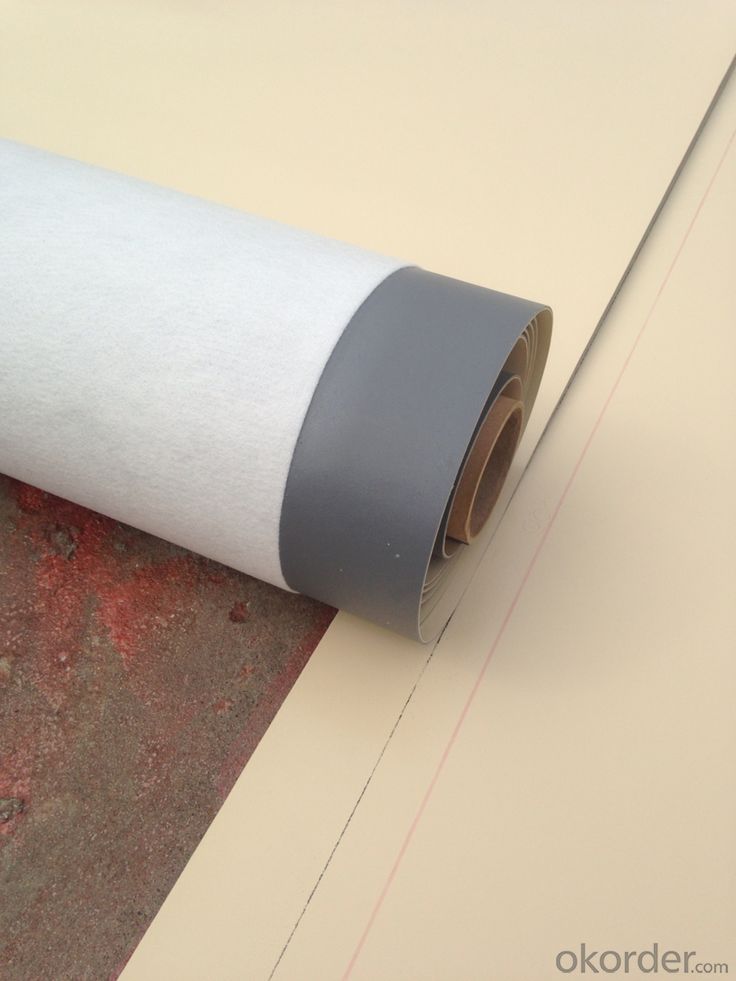

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- To handle movement joints or cracks, a waterproofing membrane is designed with flexibility and stretchability, serving as a barrier that can adapt to the shifting or settling of a structure. When there are movement joints or cracks, the membrane is applied to create a continuous and seamless layer on the surface. The waterproofing membrane's flexibility allows it to adjust to structural changes without compromising its integrity, such as expansion or contraction. This is particularly crucial in areas with significant movement or prone to crack development, like concrete slabs or foundations. In cases of movement joints, the membrane is typically terminated or divided at the joint, ensuring movement can occur without stressing or tensioning the membrane. This prevents tearing or failure caused by structural shifts. For cracks, the waterproofing membrane is directly applied over the surface, bridging the gap and sealing it off from water infiltration. Its flexibility allows it to stretch and conform to the crack's shape, effectively sealing it and preventing further water damage. Ultimately, a waterproofing membrane provides a durable and flexible barrier capable of accommodating structural movements and preventing water penetration. This safeguards the structure's integrity and shields it from water damage.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Using a waterproofing membrane in crawlspaces or basements is highly recommended. These areas are prone to water seepage and high humidity levels, which can cause mold growth, structural issues, and damage to stored items. By effectively sealing the foundation walls and floor, a waterproofing membrane acts as a barrier against water intrusion. It creates a watertight seal that keeps the space dry and protected. Furthermore, waterproofing membranes help control moisture levels by reducing condensation and humidity, creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is crucial for ensuring the structure's longevity and integrity and protecting against potential water-related problems.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- A waterproofing membrane is designed to be resistant to chemicals and solvents, allowing it to handle exposure without being damaged or deteriorated.

- Q: Can a waterproofing membrane be used for underground utility tunnels?

- Yes, a waterproofing membrane can be used for underground utility tunnels. Waterproofing membranes are designed to provide a barrier against water infiltration, and they can be applied to the exterior or interior of underground structures such as utility tunnels to prevent water damage and leaks.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. In fact, one of the advantages of waterproofing membranes is their ability to conform to various irregularities and unevenness in the surface. These membranes are typically flexible and can be easily molded and adjusted to fit the contours of the substrate. Additionally, some waterproofing membranes have self-adhesive properties or can be applied with adhesives, allowing them to adhere to both smooth and uneven surfaces effectively. However, it is important to note that proper surface preparation is crucial for a successful installation. The surface should be clean, dry, and free from any loose materials or debris to ensure optimum adhesion and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on concrete walls?

- Concrete walls can benefit from the use of a waterproofing membrane. These membranes are specifically designed to prevent water from penetrating the surface and can be applied to various surfaces, including concrete walls. Common materials used for these membranes include modified bitumen, rubberized asphalt, and synthetic polymers, all of which are highly resistant to water and moisture. By applying a waterproofing membrane to concrete walls, one can effectively prevent water seepage, dampness, and potential damage caused by water infiltration. The membrane acts as a protective barrier, stopping water from permeating through the concrete and reaching the interior spaces. Additionally, it helps maintain the structural integrity of the concrete by reducing the risks of cracks, efflorescence, and other forms of moisture-related deterioration. There are several types of waterproofing membranes available in the market, such as sheet membranes, liquid membranes, and cementitious coatings. The choice of the membrane depends on factors such as the specific application, the degree of water exposure, and the condition of the concrete wall. It is essential to select a membrane that is compatible with the concrete and provides long-lasting waterproofing protection. Before applying the membrane, it is crucial to properly prepare the concrete surface. This involves tasks such as cleaning, repairing any cracks or imperfections, and ensuring that the surface is dry and free from contaminants. The membrane is then installed according to the manufacturer's instructions, which usually involves adhering it to the concrete or applying a liquid membrane with a brush or roller. To sum up, a waterproofing membrane is a valuable solution for protecting concrete walls from water infiltration. By choosing the right type of membrane and following proper installation procedures, one can effectively preserve the durability and longevity of the concrete while safeguarding the interior spaces from potential water damage.

- Q: Does a waterproofing membrane require any specific surface preparation for tile installations?

- Yes, a waterproofing membrane does require specific surface preparation for tile installations. The success of the waterproofing membrane and the longevity of the tile installation depend on proper surface preparation. Before installing a waterproofing membrane, it is crucial to ensure that the surface is clean, dry, and free from any contaminants such as dust, debris, oil, grease, or any loose or crumbling materials. The surface should be thoroughly cleaned and any existing tile, adhesive, or grout should be removed if necessary. In addition to cleanliness, it is important to make sure the surface is smooth and even. Any uneven areas or imperfections should be leveled and patched using a suitable patching compound. This will help prevent any water from pooling or seeping underneath the waterproofing membrane, which could lead to potential issues such as leaks, mold growth, or damage to the tile installation. Furthermore, it is essential to ensure that the surface is structurally sound and stable. If there are any cracks, weak areas, or signs of instability, they should be addressed and repaired before installing the waterproofing membrane. This will help provide a solid foundation for the tile installation and prevent any future problems. Overall, proper surface preparation is crucial for the success of a waterproofing membrane and tile installation. It ensures a clean, smooth, and stable surface, which is necessary for the membrane to adhere properly and provide effective waterproofing. Following the manufacturer's guidelines and consulting with a professional if needed can help ensure the correct surface preparation for a long-lasting and reliable tile installation.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

- Q: Can a waterproofing membrane be used in agricultural structures?

- In agricultural structures, like barns, greenhouses, and storage facilities, it is possible to utilize a waterproofing membrane. These structures often necessitate protection against moisture and water harm. A waterproofing membrane is a robust and flexible substance that can be applied to diverse surfaces such as roofs, walls, and floors to obstruct water infiltration. It functions as a barrier, stopping water from penetrating the structure and causing destruction to the building materials, equipment, and stored crops. Moreover, a waterproofing membrane can also assist in regulating the temperature and humidity levels within the agricultural structure, generating a more controlled and ideal environment for crops, livestock, and equipment. In summary, the utilization of a waterproofing membrane in agricultural structures can guarantee the durability and functionality of the building while safeguarding the valuable assets inside.

- Q: Does a waterproofing membrane provide any protection against radon gas?

- A waterproofing membrane does not offer any protection against radon gas. Radon gas, which is radioactive, can enter buildings through foundation or wall cracks and openings. While a waterproofing membrane can prevent water penetration and moisture problems, it is not an effective barrier against radon gas. To protect against radon gas, specific measures for radon mitigation should be taken, such as sealing cracks, installing a radon mitigation system, or improving ventilation. It is crucial to consult with radon experts who can assess the radon levels in your region and offer suitable recommendations for mitigating the gas.

Send your message to us

Heat-resistant Polyvinyl Chloride PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords