PVC Waterproofing Membrane

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20GP m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

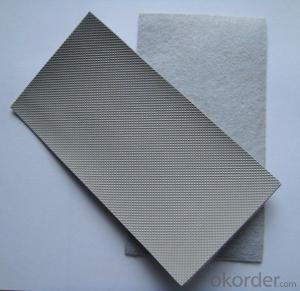

Specification Of Colored PVC Waterproofing Membrane With Good Quality From China

Width: 2m

Thickness: 1.2mm , 1.5mm , 2.0mm

Length: 20m

Features Of Colored PVC Waterproofing Membrane

1 last above 15 years

2 high quality

3 new-type waterproof materials

4 environmental

5 shapely

Application Of Colored PVC Waterproofing Membrane

PVC Waterproof Membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, Bridges,tunnel, water pools, shelter, grain depot, land filling and subway.

Pictures Of Colored PVC Waterproofing Membrane

- Q: Can a waterproofing membrane be used for bathrooms or showers?

- Yes, a waterproofing membrane can be used for bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water leakage and damage to the underlying structure. The membrane is typically applied to the walls and floor of the bathroom or shower area to create a barrier that prevents water from seeping through. This helps to protect the surrounding areas from moisture, mold, and mildew growth. Additionally, a waterproofing membrane can also help to prolong the lifespan of the bathroom or shower by preventing water damage and deterioration. Overall, using a waterproofing membrane is an effective solution to ensure the durability and longevity of bathroom and shower areas.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- When using a waterproofing membrane, there are several environmental factors to consider. One major concern is the possibility of harmful chemicals or materials being used during production. Some membranes may contain toxic substances like volatile organic compounds (VOCs) or heavy metals, which can negatively impact both human health and the environment. Another consideration is how to properly dispose of the membrane at the end of its lifespan. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Incorrect disposal methods can lead to environmental pollution and harm ecosystems. Furthermore, the production of waterproofing membranes often involves energy-intensive processes and the extraction of non-renewable resources. This can result in greenhouse gas emissions and the depletion of natural resources. To address these environmental concerns, it is crucial to select waterproofing membranes that have been made using eco-friendly materials and processes. Look for products labeled as low VOC or free from hazardous substances. Additionally, consider using recyclable membranes or those made from recycled materials to decrease waste generation. Proper disposal of the membrane at the end of its life cycle is also vital, and options such as recycling or repurposing should be explored. In conclusion, it is essential to take the environmental impact of waterproofing membranes into account and choose products and practices that minimize harm to the environment and promote sustainability.

- Q: Can a waterproofing membrane be used on both horizontal and vertical surfaces?

- Yes, a waterproofing membrane can be used on both horizontal and vertical surfaces. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the surface orientation.

- Q: Are waterproofing membranes resistant to freeze-thaw cycles?

- Yes, waterproofing membranes are generally resistant to freeze-thaw cycles. These membranes are designed to withstand extreme weather conditions, including freezing temperatures and the subsequent thawing process. The materials used in waterproofing membranes are often chosen for their durability and ability to expand and contract without compromising their waterproofing properties. This resistance to freeze-thaw cycles ensures that the membranes remain intact and effective in preventing water penetration, even in areas where temperature fluctuations occur frequently.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

- Q: Are waterproofing membranes resistant to battery acid?

- Waterproofing membranes are typically not specifically designed to be resistant to battery acid. The purpose of waterproofing membranes is to provide a barrier against water and moisture, and they are typically made of materials such as bitumen, rubber, or modified asphalt. While these materials may have some level of resistance to certain acids, they are not typically designed to withstand the corrosive properties of battery acid. Battery acid, which is typically sulfuric acid, can cause significant damage to many materials, including waterproofing membranes. If you are working with battery acid or have a situation where exposure to battery acid is a concern, it is recommended to use materials specifically designed to resist the corrosive effects of battery acid or consult with a professional for appropriate solutions.

- Q: Are waterproofing membranes suitable for stadium structures?

- Waterproofing membranes are well-suited for stadium structures. Stadiums are exposed to different weather conditions, such as rain, snow, and humidity, which can potentially harm the structure if proper waterproofing measures are not taken. By providing a protective layer that prevents water infiltration, waterproofing membranes safeguard the stadium from moisture-related problems like leaks, mold, and corrosion. Water accumulation on large roof areas and expansive seating areas is common in stadium structures, making waterproofing essential. Membranes can be applied on various surfaces, such as concrete, metal, and wood, offering a versatile and effective waterproofing solution for stadiums. Furthermore, waterproofing membranes offer durability and longevity, which is crucial for stadiums that experience heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Moreover, architects and engineers can customize waterproofing membranes to meet specific design requirements, seamlessly integrating them into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, allowing them to blend with the surrounding materials and enhance the stadium's visual appeal. In conclusion, waterproofing membranes are a reliable and effective solution for protecting stadium structures from water damage. They provide durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. However, it is important to consider the specific needs and requirements of the building. The use of a waterproofing membrane should be carefully assessed and integrated into the building's preservation and conservation plans to ensure compatibility with its historic fabric and materials. Professional advice and expertise should be sought to ensure the appropriate selection and installation of the waterproofing membrane without compromising the building's historic integrity.

- Q: Can a waterproofing membrane be used for industrial applications?

- Yes, a waterproofing membrane can be used for industrial applications. Waterproofing membranes are designed to provide a barrier against water penetration and can be used in a variety of industrial settings where protection against water intrusion is required. These membranes are commonly used in industries such as construction, manufacturing, and transportation to prevent water damage to structures, equipment, or products. They can be applied to various surfaces including roofs, walls, floors, and underground structures to provide long-lasting waterproofing solutions. Additionally, waterproofing membranes can withstand harsh environmental conditions, chemicals, and high temperatures, making them suitable for industrial applications where resistance to these factors is essential. Overall, waterproofing membranes are a reliable and effective solution for industrial waterproofing needs.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Yes, a waterproofing membrane can be used in bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. A waterproofing membrane acts as a barrier that prevents water from penetrating through the walls, floors, and other surfaces in the bathroom or shower. It is typically applied before tiling or finishing the surfaces, providing an extra layer of protection against moisture and ensuring that the underlying structure remains dry. This not only helps to prevent mold and mildew growth but also prolongs the lifespan of the bathroom or shower.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2003 |

| Annual Output Value | Above 50 Million RMB |

| Main Markets | Mid East; Eastern Europe; North America; Southeast Asia |

| Company Certifications | ISO 9001; ISO 14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 10% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 2000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

PVC Waterproofing Membrane

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20GP m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords