PVC Waterproofing Membrane with Durable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane with Durable Quality

Product Description of PVC Waterproofing Membrane with Durable Quality:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane with Durable Quality:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

Classification of PVC Waterproofing Membrane with Durable Quality:

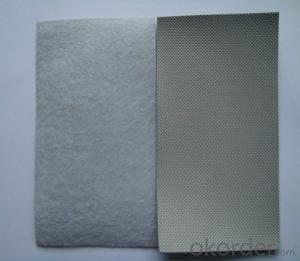

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane with Durable Quality:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane with Durable Quality:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane with Durable Quality:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

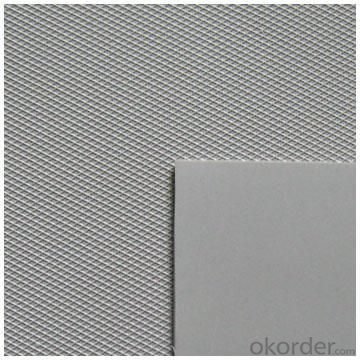

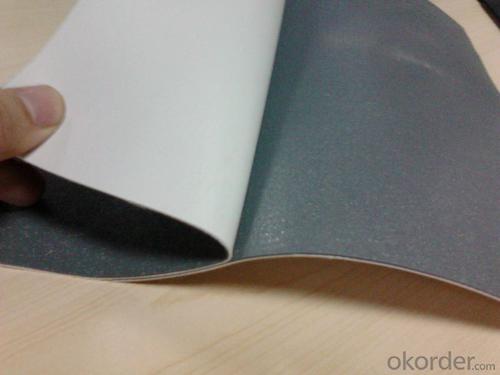

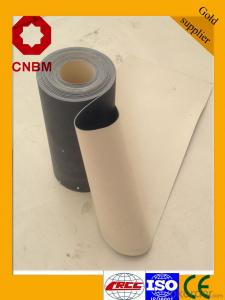

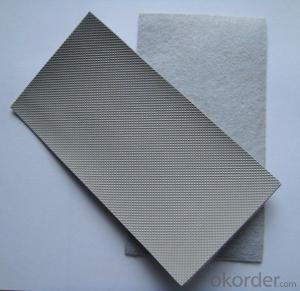

Images of PVC Waterproofing Membrane with Durable Quality:

FAQ of PVC Waterproofing Membrane with Durable Quality:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on precast steel surfaces?

- Yes, a waterproofing membrane can be used on precast steel surfaces. The membrane is designed to provide a protective layer against water penetration, making it suitable for application on various surfaces, including precast steel. This can help prevent corrosion and prolong the lifespan of the steel structure.

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Yes, a waterproofing membrane can be used on breeze block surfaces. The membrane creates a barrier that helps prevent water penetration, protecting the breeze blocks from moisture damage.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation necessary?

- Professional installation is typically recommended for waterproofing membrane installation. This is because proper installation requires specialized knowledge, skills, and equipment to ensure the membrane is correctly applied and effectively waterproofs the intended area. Hiring a professional ensures that the installation is done correctly and reduces the risk of potential water damage in the future.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can withstand various types of stress, including foot traffic and heavy loads. However, it is important to choose a waterproofing membrane that is specifically designed for these conditions. There are different types of membranes available, each with varying levels of durability and strength. It is crucial to consult with a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the area with high foot traffic or heavy loads. Proper installation and maintenance of the membrane are also essential for its long-term effectiveness in these conditions.

- Q: Can a waterproofing membrane be used for fire pit areas?

- No, a waterproofing membrane is not suitable for fire pit areas as it is designed to protect against water penetration, not heat and fire.

- Q: Can a waterproofing membrane be used on tunnels with soundproofing systems?

- Tunnels with soundproofing systems can benefit from the use of a waterproofing membrane. It is common practice to integrate waterproofing membranes with soundproofing systems in tunnels. This is because tunnels are prone to water infiltration, which can cause structural damage and impact the performance of the soundproofing system. By applying a waterproofing membrane, the tunnel can be shielded from water intrusion, ensuring the durability and efficacy of the soundproofing system. Moreover, the waterproofing membrane aids in maintaining a dry and comfortable environment in the tunnel, which is essential for the efficient operation of the soundproofing system. Therefore, combining a waterproofing membrane with a soundproofing system is highly recommended in tunnels to provide both water protection and sound insulation.

- Q: Can a waterproofing membrane be used for a stadium?

- Indeed, a stadium can benefit from the utilization of a waterproofing membrane. Specifically engineered to serve as a barrier against water infiltration, this membrane proves to be an optimal solution for safeguarding the structure of a stadium against any water-related damage. Its application can encompass various areas of the stadium, including the roof, walls, and foundation, effectively preventing leaks and the seepage of moisture. In addition, the implementation of a waterproofing membrane can play a crucial role in prolonging the lifespan of the stadium, shielding it from the detrimental consequences of water, such as corrosion and the growth of mold. In summary, the usage of a waterproofing membrane for a stadium represents a pragmatic and efficient approach to ensuring its durability and longevity.

- Q: Are waterproofing membranes UV resistant?

- Yes, waterproofing membranes are typically UV resistant. They are designed to withstand exposure to sunlight without degrading or losing their effectiveness. This UV resistance helps to prolong the lifespan of the membrane and maintain its waterproofing properties over time.

- Q: What is the meaning of "channel" and "layer" in the practice of polymer waterproofing membrane?

- In addition, the two did not meet the required thickness of the waterproof layer, according to certain requirements for laminated composite, two waterproof layer can be considered a waterproof. Such as 1.2mm polyurethane + 1.2mm self-adhesive coil (laminated construction rather than separate), can be used as a waterproof, although with two kinds of materials to do a two-story waterproof, and can not be considered two waterproof. The thickness of the laminated composite waterproofing layer can be thinned, and its provisions may be reflected in the new "roofing engineering technical specification" to be published.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Indeed, water treatment plants can benefit from the utilization of waterproofing membranes. These specialized membranes are specifically engineered to impede the flow of water, making them an ideal solution for safeguarding against water seepage in diverse structures, including water treatment plants. By applying these membranes to various sections of the facility, such as tanks, reservoirs, pipes, and basements, infiltration of water can be effectively prevented, thus shielding the infrastructure from potential harm. Furthermore, the implementation of waterproofing membranes aids in preserving the integrity of the water treatment process by ensuring that water remains confined within designated areas and does not permeate the surrounding soil or structures.

Send your message to us

PVC Waterproofing Membrane with Durable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords