Aquaseal Basement Waterproofing

Aquaseal Basement Waterproofing Related Searches

Residential Waterproofing Waterproofing Homes Waterproofing Wet Areas Soundproofing A Basement Exterior Foundation Waterproofing Materials Waterproofing Concrete Floors Waterproof Sealer Waterproofing Inspection Waterproof Admixture Concrete Basement Sealer Waterproof Seal Waterproof Material Spray Waterproof Sealant Waterproofing Concrete Block Walls Concrete Foundation Waterproofing Membrane Concrete Slab Waterproofing Commercial Waterproofing Waterproof Paint Waterproofing Atlanta Waterproof Cement Board Shower Material Waterproofing Spray Backer Board Waterproof Waterproof Concrete Blocks Waterproofing Additive For Cement Render Plastomeric Waterproofing Materials Waterproofing Felt Roof Basement Seepage Paintable Waterproof Membrane Waterproof Spray Waterproof Thermal BlanketAquaseal Basement Waterproofing Supplier & Manufacturer from China

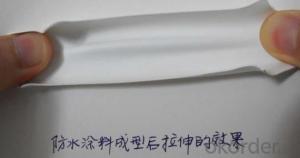

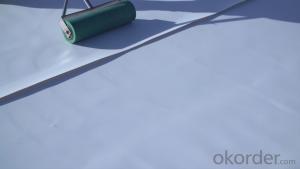

Aquaseal Basement Waterproofing is a comprehensive range of products designed to protect and preserve the structural integrity of basements and other below-grade spaces. These products include high-quality waterproofing membranes, sealants, and drainage systems that effectively manage water seepage and prevent moisture-related issues. By incorporating Aquaseal Basement Waterproofing products into construction projects, contractors and homeowners can ensure a dry, comfortable, and safe living environment.The application of Aquaseal Basement Waterproofing products is versatile and can be utilized in various scenarios, such as new construction, home renovations, or even for addressing existing water damage. These products are particularly useful in areas with high water tables or in regions prone to flooding. By applying Aquaseal Basement Waterproofing systems, property owners can safeguard their investments and prevent costly repairs in the future.

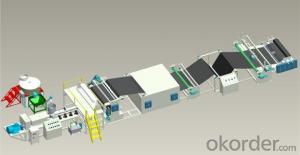

Okorder.com is a reputable wholesale supplier of Aquaseal Basement Waterproofing products, boasting a large inventory that caters to the needs of both residential and commercial clients. With a commitment to providing top-quality materials at competitive prices, Okorder.com has become a go-to source for contractors and homeowners seeking reliable and effective waterproofing solutions.

Hot Products