Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing:

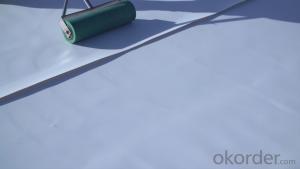

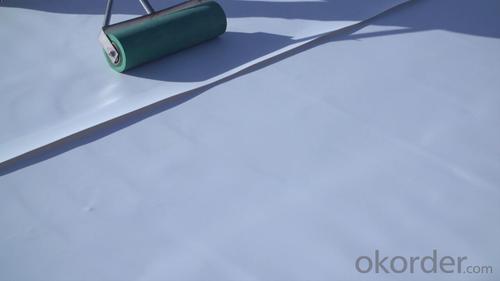

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Applications of Thermoplastic Polyolefin (TPO)Roofing Membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc."

Data Sheet of Thermoplastic Polyolefin (TPO)Roofing Membrane:

Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

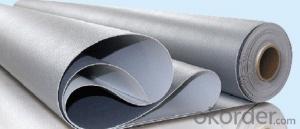

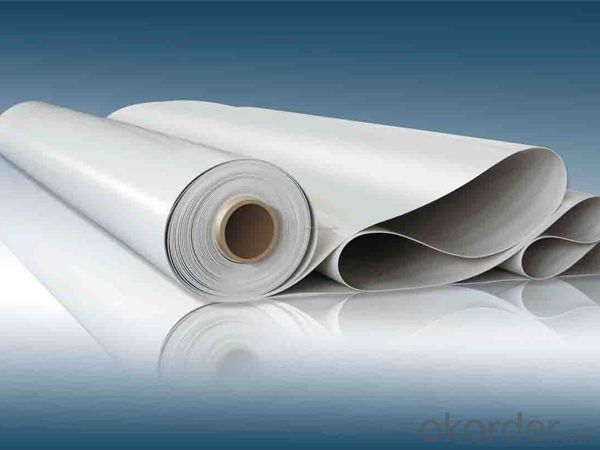

Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: How does a waterproofing membrane handle water migration through the substrate?

- A waterproofing membrane is designed to prevent water migration through the substrate. It acts as a barrier, preventing water from infiltrating the substrate and causing damage to the structure. The membrane is typically applied to the exterior side of the substrate, creating a watertight seal. To handle water migration, the membrane is typically made from a flexible and durable material such as modified bitumen, PVC, or EPDM. These materials have excellent waterproofing properties and can withstand exposure to water, UV rays, and other environmental factors. The membrane is installed in a way that ensures proper adhesion to the substrate, creating a seamless and continuous barrier. It is often applied in multiple layers to further enhance its effectiveness. The seams and joints are also properly sealed to prevent any potential water leaks. In addition to its primary waterproofing function, the membrane also helps to manage water that may accumulate on the surface. It is designed with a slope or drainage system, directing water away from critical areas and towards appropriate outlets or drains. Overall, a waterproofing membrane is specifically engineered to handle water migration through the substrate by creating a reliable and long-lasting barrier against moisture. It is an essential component in protecting structures from water damage and ensuring their durability and longevity.

- Q: Can waterproofing membranes be applied over existing surfaces?

- Yes, waterproofing membranes can be applied over existing surfaces. In fact, this is a common practice in construction and renovation projects. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied over various surfaces such as concrete, wood, metal, or even other waterproofing systems. By applying a waterproofing membrane over an existing surface, it helps to prevent water damage, including leaks, mold growth, and structural deterioration. However, it is important to ensure that the existing surface is properly prepared and cleaned before the membrane application to achieve optimal adhesion and performance. Additionally, it is recommended to consult with a professional waterproofing contractor to determine the most suitable membrane type and installation method for the specific project requirements.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Yes, there are some drawbacks and limitations to using a waterproofing membrane. One limitation is that it can be expensive to install, especially if it requires professional assistance. Additionally, if the membrane is not properly installed or maintained, it can become damaged or ineffective over time. Another drawback is that waterproofing membranes can limit the breathability of a structure, which can lead to moisture buildup and potential issues with mold or mildew. Finally, while a waterproofing membrane can protect against water intrusion, it may not fully address other potential sources of moisture, such as condensation or groundwater seepage.

- Q: What type of maintenance is required for a waterproofing membrane?

- To properly maintain a waterproofing membrane, regular inspections and routine maintenance are necessary. Firstly, it is important to keep the surface clean and free from debris that could potentially damage the membrane. Regularly remove any dirt, leaves, or other foreign materials that may accumulate on the surface. Inspect the membrane for any signs of wear, tear, or damage, such as cracks, blisters, or punctures. If any issues are found, they should be repaired promptly to prevent water leakage and potential further damage. Additionally, it is recommended to inspect and maintain the surrounding areas of the membrane, including gutters, downspouts, and drainage systems. Ensure that these components are functioning properly and free from any blockages that could compromise the effectiveness of the waterproofing system. Depending on the type of waterproofing membrane used, it may require periodic reapplication of a protective coating or sealant. This will help to extend the lifespan of the membrane and ensure its continued effectiveness. It is also essential to monitor the membrane's performance during heavy rain or snow events. Check for any signs of water pooling or leakage, and address any problems promptly. Overall, regular inspections, routine cleaning, prompt repairs, and necessary reapplication of protective coatings are key maintenance tasks to ensure the longevity and effectiveness of a waterproofing membrane.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to handle movement of a building caused by settling or seismic activity by providing flexibility and elasticity. It can accommodate small shifts and vibrations without cracking or breaking, ensuring that the waterproof barrier remains intact. The membrane's ability to stretch and contract helps it to adapt to the movement of the structure, preventing water intrusion and maintaining its effectiveness in safeguarding the building against moisture damage.

- Q: Can a waterproofing membrane be used on steel surfaces?

- Yes, a waterproofing membrane can be used on steel surfaces. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and they can effectively adhere to and seal steel surfaces, preventing water penetration and potential damage.

- Q: Can a waterproofing membrane be used for elevator pits and sump pits?

- Yes, a waterproofing membrane can be used for elevator pits and sump pits. Elevator pits and sump pits are generally prone to water leakage and moisture issues, which can cause damage to the structural integrity of the pits and surrounding areas. To prevent such issues, waterproofing membranes are commonly used to create a barrier against water intrusion. A waterproofing membrane is designed to be highly resistant to water penetration and can effectively seal the elevator and sump pits, preventing water from seeping in. These membranes are typically made of materials such as rubberized asphalt, ethylene propylene diene terpolymer (EPDM), or polyvinyl chloride (PVC) and are applied to the walls and floors of the pits. By installing a waterproofing membrane, the elevator and sump pits can be protected from water damage, including potential corrosion, mold growth, and structural deterioration. This not only helps to maintain the functionality and longevity of the pits but also ensures a safe and healthy environment for occupants and equipment. However, it is important to consider the specific requirements and regulations of elevator and sump pit installations, as different jurisdictions may have specific codes and standards that need to be followed. Additionally, proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its effectiveness in preventing water infiltration.

- Q: How does a waterproofing membrane handle construction joints?

- A waterproofing membrane is designed to provide a protective barrier against water penetration in construction applications. When it comes to construction joints, which are commonly found in concrete structures, the membrane is specifically engineered to handle these areas. During the construction process, joints are created to allow for movement between different sections of the structure. These joints can be vulnerable points where water can potentially infiltrate. To address this concern, waterproofing membranes are installed to ensure that these joints remain watertight. There are different methods used to handle construction joints with waterproofing membranes. One common approach is to apply the membrane directly over the joint, extending it beyond the joint edges. This creates a continuous waterproof layer that covers both the joint and the adjoining areas. Another technique involves the use of specially designed joint tapes or strips that are embedded within the membrane. These tapes or strips are typically made of materials like rubber or PVC and are placed directly over the joint before the membrane is applied. They serve as an additional layer of protection, enhancing the waterproofing performance of the membrane at the joint. In addition to these methods, there are also specialized waterproofing systems available that include pre-formed joint sealants. These sealants are designed to fit snugly into the joint, providing a tight seal against water intrusion. The membrane is then installed over the joint, ensuring comprehensive waterproofing coverage. Overall, a waterproofing membrane is specifically designed to handle construction joints by providing a durable and effective barrier against water penetration. Whether through extending the membrane over the joint, using joint tapes or strips, or incorporating pre-formed joint sealants, these membranes ensure that construction joints remain watertight, protecting the structure from potential water damage.

- Q: Can a waterproofing membrane be used in areas with heavy rainfall or high water tables?

- Yes, a waterproofing membrane can be used in areas with heavy rainfall or high water tables. Waterproofing membranes are specifically designed to prevent water infiltration and can effectively protect structures from water damage. These membranes are made from materials such as bitumen, rubber, or polyurethane, which provide a barrier against moisture. They are installed on the exterior side of walls, roofs, or foundations to create a watertight seal. In areas with heavy rainfall or high water tables, it is crucial to use a high-quality and durable waterproofing membrane that can withstand the constant exposure to water. Additionally, proper installation techniques and regular maintenance are essential to ensure the effectiveness of the waterproofing system.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures and tears. It is specifically engineered to provide a durable barrier that can withstand potential damage from sharp objects or external forces.

Send your message to us

Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords