Products Description of TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

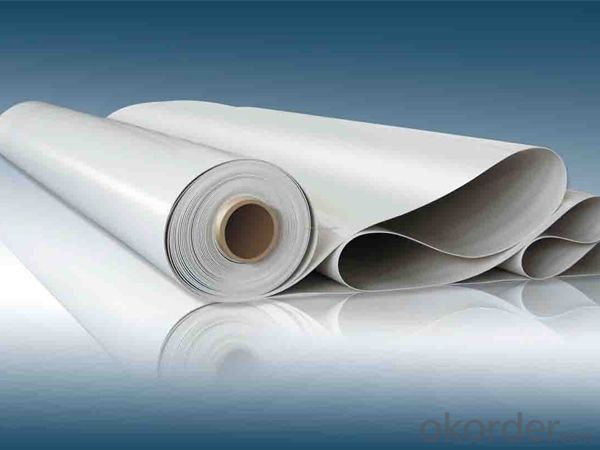

Products Description of TPO Waterproof Membrane for Roofing Construction:

The Thermoplastic Polyolefin (TPO) waterproof membranes are the most popular waterproof materials in the world at present. It’s thermoplastic elastomeric waterproof materials by adopting advanced polymerization together with squeeze technology,which perform well in mechanical properties, high tensile strength,oxidation-resistance and resistance to puncture.

Product Features of TPO Waterproof Membrane for Roofing Construction:

--High UV-resistance and high reflectivity

--Excellent weathering characteristics and long-term flexibility

--High tensile strength and puncture resistance

--Excellent resistance to harsh chemicals and industrial pollutas

--Heat or solventwelding effectively provides seamless roof covering

Data Sheet of TPO Waterproof Membrane for Roofing Construction:

Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can certainly be used on roofs with skylights. In fact, it is highly recommended to use a waterproofing membrane around skylights to prevent any water infiltration or leakage. Skylights are potential weak points in a roof system, as they create openings that can allow water to seep through if not properly sealed. By applying a waterproofing membrane around the skylights, it helps to create a watertight barrier that protects the roof from any potential leaks. Additionally, a waterproofing membrane can also provide added protection against other elements such as UV rays and temperature fluctuations, prolonging the lifespan of both the skylights and the roof itself.

- Q: Can a waterproofing membrane be walked on?

- Walking on a waterproofing membrane is possible, but it depends on the type of membrane and its intended use. Some waterproofing membranes, like those used in roofing, are designed to withstand foot traffic without damage. These membranes are durable and can be walked on during installation and maintenance. However, it is crucial to follow the manufacturer's guidelines to ensure the membrane remains intact and provides effective waterproofing. On the other hand, certain types of below-grade waterproofing membranes may not be suitable for walking on as it could compromise their performance. It is advisable to consult a professional or refer to the manufacturer's instructions to determine if walking on a specific waterproofing membrane is safe and appropriate.

- Q: Can a waterproofing membrane be used for elevator shafts and stairwells?

- Elevator shafts and stairwells, being susceptible to moisture and water infiltration, can indeed benefit from the use of a waterproofing membrane. Particularly in below-grade or high-moisture environments, these areas are prone to such issues. The purpose of waterproofing membranes is to create a barrier that prevents water from penetrating and causing damage to the structure. When properly applied, a waterproofing membrane can effectively safeguard elevator shafts and stairwells, ensuring they remain dry and free from problems associated with water, such as mold growth, material deterioration, and structural damage. These membranes are typically constructed using durable materials like modified bitumen, PVC, or rubberized asphalt, which possess excellent waterproofing qualities. It is crucial to select a waterproofing membrane specifically designed for below-grade or high-moisture applications. These membranes should possess high resistance to hydrostatic pressure, the ability to bridge cracks, and long-term durability to withstand constant exposure to moisture. Moreover, it is important to have trained professionals with expertise in waterproofing systems handle the installation of the membrane in elevator shafts and stairwells. This will guarantee correct installation, resulting in an effective barrier against water infiltration. In conclusion, a waterproofing membrane is a suitable solution for elevator shafts and stairwells, providing effective protection against water penetration and related moisture issues.

- Q: Can a waterproofing membrane be used in conjunction with vapor barriers?

- Yes, a waterproofing membrane can be used in conjunction with vapor barriers. While a waterproofing membrane protects against liquid water infiltration, a vapor barrier is designed to prevent the passage of moisture vapor. By combining both, you can effectively protect a structure from both liquid water and moisture vapor, ensuring a comprehensive moisture management system.

- Q: Can a waterproofing membrane be painted or covered with a protective layer?

- Yes, a waterproofing membrane can be painted or covered with a protective layer. This can help enhance its durability and resistance to external elements. However, it is important to ensure that the paint or protective layer used is compatible with the waterproofing membrane to maintain its effectiveness and prevent any potential damage.

- Q: Can a waterproofing membrane be used for a green roof system?

- Yes, a waterproofing membrane can be used for a green roof system. In fact, a high-quality waterproofing membrane is an essential component of a green roof system. Green roofs are designed to support the growth of vegetation and require a durable and reliable waterproofing barrier to prevent water leakage and protect the underlying structure from moisture damage. A waterproofing membrane acts as a protective layer, effectively sealing the roof and preventing water from penetrating into the building. Additionally, the membrane helps to retain water within the green roof system, ensuring that the plants receive an adequate water supply. Therefore, integrating a waterproofing membrane into a green roof system is crucial for its success and longevity.

- Q: How does a waterproofing membrane handle water pressure from adjacent structures?

- A waterproofing membrane is designed to handle water pressure from adjacent structures by acting as a barrier that prevents water from seeping through. It resists the force exerted by the water pressure and ensures that no water can penetrate into the protected area.

- Q: Can a waterproofing membrane be used for loading docks?

- Yes, a waterproofing membrane can be used for loading docks. Waterproofing membranes are commonly used in various construction applications to protect the underlying structures from moisture and water damage. Loading docks, being exposed to a high level of foot and vehicle traffic as well as potential water infiltration, can benefit from the installation of a waterproofing membrane. A waterproofing membrane creates a barrier against water intrusion, preventing moisture from seeping into the loading dock area. This is particularly important as moisture can weaken the structural integrity of the dock, leading to potential damage and safety hazards. By installing a waterproofing membrane, loading docks can be protected from water-related issues such as corrosion, mold, and deterioration. In addition to water protection, some waterproofing membranes also offer other benefits such as anti-slip properties or resistance to chemicals and oils, which can be advantageous in a loading dock environment. These additional features enhance the safety and durability of the loading dock, making it more suitable for heavy loads and frequent use. It is important to note that when selecting a waterproofing membrane for loading docks, consideration should be given to the specific requirements and conditions of the dock area. Factors such as the type of traffic, load capacity, and exposure to harsh environments should be evaluated to ensure that the chosen membrane is suitable for the intended use. In conclusion, a waterproofing membrane can be effectively used for loading docks to protect against water damage, enhance safety, and improve the longevity of the structure.

- Q: Are waterproofing membranes resistant to hydrocarbons?

- Yes, waterproofing membranes are generally resistant to hydrocarbons. They are designed to provide a barrier against water and other liquids, including hydrocarbons, preventing them from penetrating through the membrane and causing damage to the underlying structure.

- Q: Does a waterproofing membrane require any special considerations for installation in earthquake-prone areas?

- Installation of a waterproofing membrane in earthquake-prone areas necessitates special considerations. The ground in these regions is more susceptible to movement and shaking, which can greatly impact the integrity of the waterproofing system. Therefore, it is crucial to take additional precautions to ensure that the membrane is installed properly and capable of withstanding seismic activity. One important factor to consider is the choice of the waterproofing membrane itself. It is advisable to select a membrane that has been specifically designed and tested to endure seismic activity. These membranes are typically more flexible and possess higher tensile strength to accommodate ground movement during earthquakes. Moreover, the installation process should be executed with utmost care and attention to detail. The membrane should be securely anchored or fastened to the substrate using appropriate fasteners and adhesives. Reinforcement techniques, such as using reinforcing fabric or mesh, can also be employed to enhance the membrane's resistance to movement. Additionally, it is essential to ensure that all seams and joints in the membrane are adequately sealed and reinforced. Special attention should be given to areas that are more prone to movement, such as corners, edges, and penetrations. Utilizing compatible and high-quality sealants or adhesives will assist in maintaining the integrity of these vulnerable points. Regular inspections and maintenance are also critical in earthquake-prone areas. Periodically inspecting the membrane for any signs of damage, such as cracks or separations, allows for early detection and timely repairs. Additionally, it is vital to have a contingency plan in place to address any potential damage that may occur during an earthquake, including emergency repair procedures. In conclusion, the installation of a waterproofing membrane in earthquake-prone areas requires careful consideration and adherence to specific guidelines. By selecting an appropriate membrane, properly anchoring and reinforcing it, ensuring proper sealing of seams and joints, and conducting regular inspections, the waterproofing system can be better prepared to withstand earthquakes and provide long-lasting protection against water intrusion.

Send your message to us

Products Description of TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords