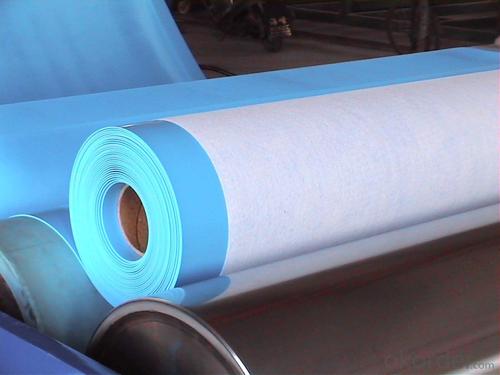

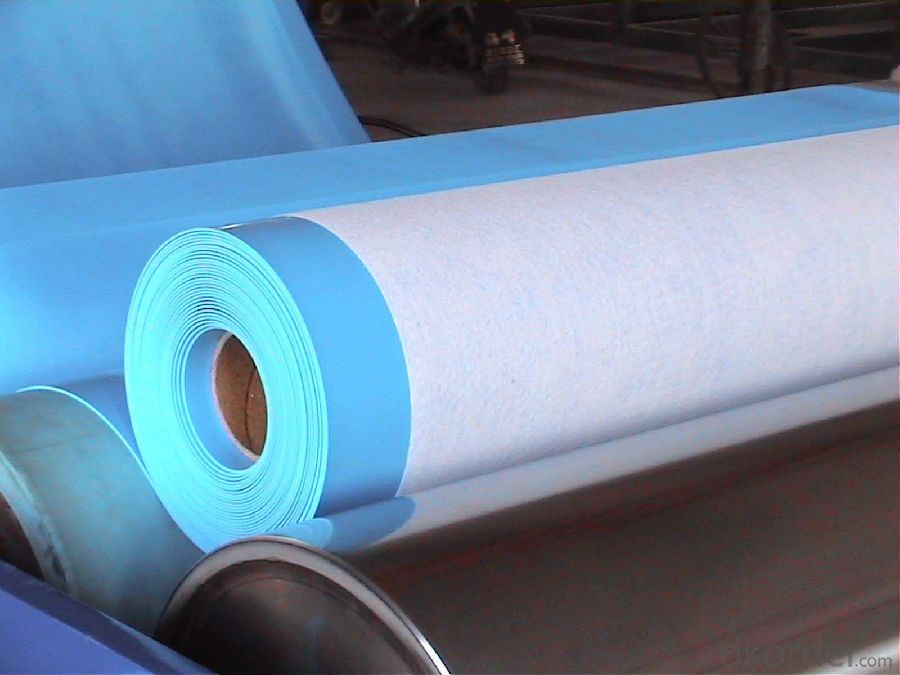

Tpo waterproof Roofing Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO membrane:

Tpo waterproof roofing membrane for sale

1.high breathable membrane

2.market:all over the world

3.resonable price

Main Features of TPO membrane:

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Specifications of TPO membrane:

name | type

| The weight of per square meter | thickness | On the surface of the material

| On the surface of the material

|

Slope roofing waterproof adhesive polymer asphalt waterproof cushion layer

| PPPETnon-woven fabrics

| 500g | 0.8mm | Black polypropylene

| Black polypropylene

|

550g | 0.9mm | White polypropylene

|

| ||

600g | 0.9mm | Colored polypropylene

| PE | ||

600g | 0.9mm | PE | PE | ||

700g | 1.0mm | Black polypropylene

| Black polypropylene

| ||

700g | 1.0mm | PE | PE | ||

700g | 1.0mm |

| PE | ||

1100g | 1.2mm | Black polypropylene

| PE | ||

1200g | 1.2mm |

| PE | ||

1500g | 1.4mm |

| PE | ||

1500g | 1.5mm |

|

| ||

2200g | 2.0mm |

|

Applications of TPO membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are there any specific considerations for installing a waterproofing membrane on metal surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on metal surfaces. Firstly, it is important to ensure that the metal surface is clean, free from rust, and properly prepared before applying the membrane. Additionally, compatibility between the waterproofing membrane and the metal surface should be checked to ensure proper adhesion. It is also crucial to select a membrane that is designed to withstand the expansion and contraction of metal due to temperature changes. Lastly, proper installation techniques should be followed to ensure a watertight seal and prevent any potential damage to the metal surface.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

- Q: Can a waterproofing membrane be used for power plants?

- Yes, a waterproofing membrane can be used for power plants. Waterproofing membranes are commonly used in power plants to protect the structural elements and equipment from water damage and leakage. These membranes are designed to provide a durable, watertight seal that can withstand the harsh conditions and high moisture levels typically found in power plant environments. Additionally, they also help in preventing corrosion and extending the lifespan of the power plant infrastructure.

- Q: Can a waterproofing membrane be used for mechanical rooms?

- A waterproofing membrane is suitable for mechanical rooms where various equipment and systems are housed. These rooms require protection from water damage. Waterproofing membranes create a barrier that prevents water from penetrating the structure, which could potentially harm the mechanical equipment. To ensure a watertight environment that extends the lifespan of the equipment and reduces the risk of water-related issues, apply the waterproofing membrane to the walls, floors, and even ceilings of the mechanical room. Moreover, waterproofing membranes also safeguard against other forms of moisture, such as condensation or high humidity levels, which can negatively impact the functionality of mechanical systems. In conclusion, utilizing a waterproofing membrane in mechanical rooms is a practical and effective method to safeguard the equipment and maintain a dry and operational environment.

- Q: Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. Waterproofing membranes are designed to prevent water penetration and moisture buildup, making them an ideal solution for areas that are prone to water damage, such as basements, bathrooms, and kitchens. These membranes create a barrier that prevents water from seeping through floors, walls, or other surfaces, effectively protecting the structure from water-related issues like mold, rot, and structural damage. Additionally, waterproofing membranes can also help regulate humidity levels, leading to a more comfortable and healthier indoor environment.

- Q: How does a waterproofing membrane adhere to a surface?

- A waterproofing membrane adheres to a surface through the use of special adhesives or sealants that are specifically designed to bond with the material of the surface. These adhesives create a strong and durable bond between the membrane and the surface, ensuring that it remains securely in place and effectively prevents the penetration of water or moisture.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls. Waterproofing membranes are designed to create a barrier against moisture, preventing water from penetrating the surface and causing damage. While they are commonly used on exterior walls to protect against rain and groundwater, they can also be used on interior walls in areas that are prone to moisture, such as bathrooms, kitchens, or basements. By applying a waterproofing membrane, you can effectively protect the interior walls from water damage, mold growth, and other moisture-related issues. It is important to note that the specific type of waterproofing membrane and the proper installation technique should be determined based on the specific needs and conditions of the interior walls. Consulting with a professional or following manufacturer guidelines is recommended to ensure proper application and long-lasting protection.

- Q: Can a waterproofing membrane be used for train platforms?

- Yes, a waterproofing membrane can be used for train platforms. Waterproofing membranes are commonly used in construction to provide a protective barrier against water and moisture. By applying a waterproofing membrane to train platforms, it helps prevent water ingress, which can cause damage to the structure and pose safety risks.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- When installing a waterproofing membrane, there are various safety precautions to consider. To begin with, it is crucial to ensure that the installation team uses all necessary personal protective equipment (PPE). This may incorporate gloves, safety glasses, and appropriate footwear to prevent injuries or exposure to dangerous substances. Moreover, it is essential to work in a well-ventilated area to avoid inhaling fumes or vapors emitted during the installation process. If working in a confined space, it is necessary to take proper measures to guarantee sufficient ventilation and use suitable respiratory protection if needed. Furthermore, it is vital to adhere to the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This involves understanding any potential hazards linked with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to make sure that the installation area is appropriately prepared before commencing the process. This might entail clearing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and easily accessible first aid kits in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to promptly identify and address any potential safety risks. By adhering to these safety precautions, the installation of a waterproofing membrane can be carried out securely and effectively, minimizing the risk of accidents or injuries.

- Q: What are the different thickness options for a waterproofing membrane?

- The different thickness options for a waterproofing membrane typically range from 10 mils to 40 mils, with some specialty options available in even greater thicknesses.

Send your message to us

Tpo waterproof Roofing Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords