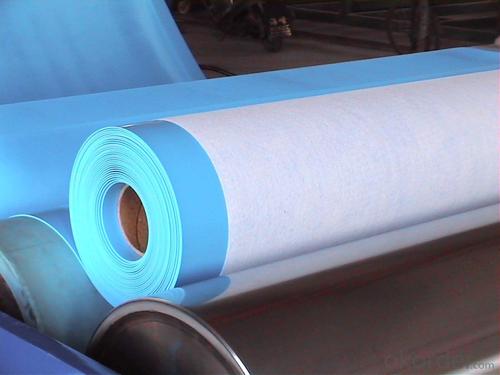

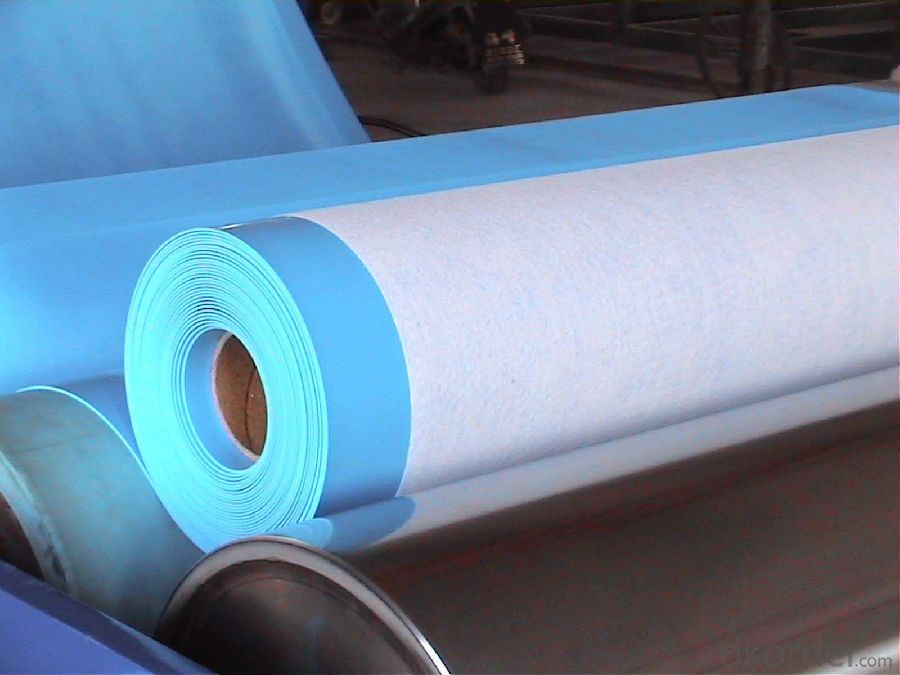

TPO Waterproof Membrane for Rooftop and Room

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO Waterproof Membrane:

Thermoplastic polyolefin (TPO) membrane is based on polypropylene and EP (ethylene-propylene) rubber polymerized together by using state-of-the-art polymer manufacturing technology. This technology enables TPO membranes flexible at low temperatures without the use of polymeric or liquid plasticizers.TPO membranes fall into two main types: Homogeneous TPO & Reinforced TPO. Reinforced TPO has a polyester mesh layer in the middle, which provides reinforced membranes with high breaking and tearing strength and puncture resistance."

Main Features of TPO Waterproof Membrane:

1. Manufactuer

2. Outstanding dimensional stability

3. High puncture resistance

4. Excellent chemical and environmental stress-cracking resistance

5. Good tensible strength

6. ISO and CE certificate

7. Easy to install

8. Customerized specification possible

Specifications of TPO Waterproof Membrane:

| Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

| Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

| 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

| Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

Applications of TPO Waterproof Membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Yes, a waterproofing membrane can be applied to horizontal surfaces. In fact, it is commonly used to protect and waterproof horizontal surfaces such as roofs, decks, balconies, and other flat areas. The membrane acts as a barrier, preventing water from penetrating the surface and causing damage. It is typically made of a flexible material, such as rubber or modified bitumen, which can easily conform to the contours of the horizontal surface. Additionally, the membrane is designed to withstand foot traffic and other loads, ensuring long-lasting protection. Overall, applying a waterproofing membrane to horizontal surfaces is an effective way to prevent water damage and extend the lifespan of the surface.

- Q: Can a waterproofing membrane be used for a rooftop garden protection?

- Yes, a waterproofing membrane can be used for rooftop garden protection. Waterproofing membranes are designed to create a barrier against water penetration, preventing leaks and protecting the underlying structure. By installing a waterproofing membrane on the rooftop, it helps to protect the garden and prevent water damage to the building.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane does require specific cleaning methods. It is important to clean the membrane regularly to maintain its effectiveness and longevity. The specific cleaning methods will depend on the type of waterproofing membrane being used, as different materials may have different cleaning requirements. In general, it is recommended to use gentle cleaning solutions and tools, such as a soft brush and mild detergent, to clean the membrane. It is important to avoid using harsh chemicals or abrasive materials that could damage the membrane. Additionally, regular inspection of the membrane for any signs of damage or debris accumulation is essential, as addressing these issues promptly can help prevent further damage and ensure the membrane continues to provide effective waterproofing. Consulting the manufacturer's guidelines and recommendations for cleaning and maintenance is highly recommended to ensure proper care of the waterproofing membrane.

- Q: Can waterproofing membranes be used on outdoor decks?

- Yes, waterproofing membranes can be used on outdoor decks. They provide an effective barrier against water and moisture, protecting the deck's structure and preventing damage from weather elements. Waterproofing membranes help to extend the lifespan of the deck and maintain its aesthetic appeal.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls. In fact, it is highly recommended to use a waterproofing membrane on below-grade walls to protect them from water infiltration and moisture damage. Below-grade walls are particularly vulnerable to water penetration due to their proximity to the ground and potential for hydrostatic pressure. A waterproofing membrane acts as a barrier, preventing water from seeping into the walls and causing issues such as mold, mildew, rot, and structural damage. It helps to keep the interior of the building dry, preventing potential moisture-related problems.

- Q: Can a waterproofing membrane be used for foundation walls?

- Yes, a waterproofing membrane can be used for foundation walls. Waterproofing membranes are commonly used to protect foundation walls from moisture, preventing water penetration and potential damage to the structure. These membranes are designed to create a protective barrier against water, helping to keep the foundation dry and maintaining its structural integrity.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. These membranes provide an effective barrier against water infiltration, protecting the structure from potential damage caused by moisture. Additionally, waterproofing membranes are flexible and can accommodate movement in the stadium's structure without compromising their effectiveness.

- Q: Can a waterproofing membrane be used for a stadium?

- Yes, a waterproofing membrane can be used for a stadium. A waterproofing membrane is designed to provide a barrier against water infiltration, making it an ideal solution for protecting the structure of a stadium from water damage. It can be used on various parts of the stadium, including the roof, walls, and foundation, to prevent leaks and moisture seepage. Additionally, a waterproofing membrane can help to extend the lifespan of the stadium by protecting it from the harmful effects of water, such as corrosion and mold growth. Overall, using a waterproofing membrane for a stadium is a practical and effective way to ensure its durability and longevity.

- Q: Basement SBS Waterproof Coil Division I and II type What is the difference? How is the site identified?

- SBS type I and type II differences are mainly low temperature flexibility and tensile extension

- Q: Whether the polyester waterproofing membrane can be used for roofing waterproofing

- 2, roof waterproofing is not just a layer of waterproof membrane, according to the design of the coating is usually used waterproof layer + polyester membrane waterproof layer;

Send your message to us

TPO Waterproof Membrane for Rooftop and Room

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords