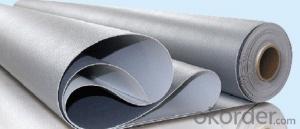

Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product features of TPO Waterproof Membrane for Roofing Market:

1.high reflectivity,anti-ultraviolet radiation,do not need to be protection,energy saving and environmental protection.

2.long-term weathering resistance,resistance to ultravoilet radiation and heat aging,density is small.

3..high elasticity,high strength,high elongation,good suppleness.

4.effectively resist harmful chemicals,industrial pollutants erosion,wear resistance,resistance to puncture.

5.with automatic quench.

Features of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

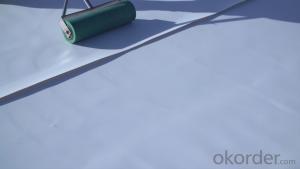

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Applications of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc."

Technical Parameters of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

No. | Item | Index | |||

1 | mm≥ thickness of resin layer above inermediate tire mm ≥ | - | - | 0.4 | |

2 | tensile property | N/cm ≥ maximum tensile force N/cm ≥ | - | 200 | 250 |

MPa ≥ tensile Strength MPa ≥ | 12.0 | - | - | ||

≥ elongation at maximun tensile force% ≥ | - | - | 15 | ||

% ≥ elongation at fracture % ≥ | 500 | 250 | - | ||

3 | size change rate under heat treatment %≤ | 2.0 | 1.0 | 0.5 | |

4 | flexibility at low temperature | no crack at -40°c | |||

5 | unpermeability | 0.3Mpa,2h waterproof | |||

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: Does a waterproofing membrane provide any insulating properties?

- A waterproofing membrane does not offer any insulation. Its main purpose is to stop water or moisture from entering a building or roof. It acts as a protective barrier, preventing damage to the underlying materials. Insulation, on the other hand, is specifically designed to minimize the transfer of heat, sound, or electricity. While both waterproofing and insulation are crucial for maintaining a structure's integrity and functionality, they serve distinct purposes and should not be mistaken for each other.

- Q: Can waterproofing membranes be used on expansion joints?

- Indeed, expansion joints can benefit from the utilization of waterproofing membranes. These joints serve the purpose of accommodating movement while safeguarding against harm brought about by the expansion or contraction of construction materials due to thermal fluctuations. By applying waterproofing membranes to these joints, a protective barrier is established, effectively impeding the infiltration of water. This serves to preserve the joint's structural integrity and prevent water-induced damage to adjacent areas. It is imperative to carefully select a flexible waterproofing membrane that can endure the joint's movements without incurring cracks or deterioration. Furthermore, the employment of proper installation techniques is crucial to ensuring a watertight seal around the expansion joint.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Basements and foundations can benefit greatly from the use of a waterproofing membrane. It is highly recommended to apply this protective layer in order to safeguard against water infiltration and moisture-related problems. Typically, the membrane is applied on the outer side of the foundation walls and basement floors, effectively creating a barrier that prevents water from permeating through the concrete. This essential measure ensures that the basement and foundation remain dry, minimizing the risk of water damage, mold growth, and structural complications. There are several types of waterproofing membranes available, including bituminous, rubberized asphalt, and liquid-applied options. This variety allows for flexibility when selecting the most suitable option according to the specific project requirements. Ultimately, installing a waterproofing membrane is a reliable means of improving the overall resilience and longevity of basements and foundations.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Vehicular traffic areas can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier that prevents water from seeping through and causing damage to surfaces. In areas like parking decks or driveways, it is crucial to protect the underlying structure from water infiltration, which can lead to corrosion, deterioration, and expensive repairs. By utilizing a waterproofing membrane that is specifically designed for vehicular traffic, the surface can be effectively safeguarded from water damage, as well as other potential contaminants such as oil and chemicals. These membranes are typically more durable and capable of withstanding the weight and impact of vehicles, ensuring long-lasting protection. Furthermore, certain waterproofing membranes even offer slip-resistant properties, making them suitable for areas where vehicles require traction. Nevertheless, it is important to seek guidance from a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas, taking into account factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. Terraces and patios are exposed to various weather conditions, including rain and snow, which can lead to moisture seeping into the underlying structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the surface and protecting the integrity of the terrace or patio. It helps to extend the lifespan of the structure and prevents costly repairs in the long run. Additionally, using a waterproofing membrane also helps to create a more comfortable and usable space, as it eliminates the risk of water accumulation and potential slip hazards. Overall, investing in a high-quality waterproofing membrane is a wise decision for anyone looking to protect their terrace or patio from water damage.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Indeed, tile surfaces can be protected using a waterproofing membrane. This membrane, a slim material layer, serves the purpose of obstructing the infiltration of water or moisture into the underlying surface. Typically utilized in locations with elevated water exposure levels, such as bathrooms, showers, or outdoor areas, a properly applied waterproofing membrane forms a safeguard for the tile surface, thwarting water damage and averting problems like mold, mildew, or tile deterioration. It is crucial to ascertain that the waterproofing membrane is suitable for the specific type of tile employed, and that it is installed accurately to guarantee optimal effectiveness.

- Q: Does a waterproofing membrane have any fire-resistant properties?

- No, a waterproofing membrane does not typically have any fire-resistant properties.

- Q: Can waterproofing membranes be used on plant rooms?

- Indeed, plant rooms can benefit from the utilization of waterproofing membranes. Within these rooms, one can typically find various apparatus and machinery that necessitate safeguarding against potential water harm. By implementing waterproofing membranes, a formidable defense is established to impede water infiltration, averting leaks and potential destruction to both the plant room and its contents. Typically, these membranes are administered to the walls, floors, and roofs of the plant room to ensure comprehensive waterproofing. Moreover, in addition to their water resistance, these membranes possess the ability to shield against other elements such as chemicals and fluctuations in temperature, rendering them an optimal solution for plant rooms.

- Q: Can a waterproofing membrane be used on foam block surfaces?

- Yes, a waterproofing membrane can be used on foam block surfaces. The membrane acts as a protective barrier, preventing water penetration and ensuring the foam blocks remain waterproof.

- Q: Can a waterproofing membrane be certified or approved by industry organizations?

- Yes, a waterproofing membrane can be certified or approved by industry organizations. These organizations typically have stringent standards and testing procedures in place to ensure that the membrane meets certain performance criteria for waterproofing applications. Certification or approval from such organizations provides assurance of the quality and reliability of the product, giving confidence to consumers and industry professionals.

Send your message to us

Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords