Polymer Adhesive Modified Asphalt Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

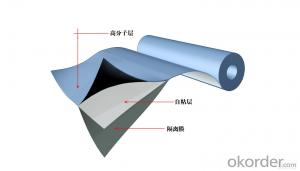

1.Structure of Polymer Adhesive Waterproofing Membrane Description:

Polymer adhesive waterproofing membrane is made of polymer sheet (PVC, PE, EVA, the ECB, TPO, etc.), since the sticky rubber asphalt rubber, the isolation membrane composition, and can according to need in polymer material compound fabric reinforced. Theproduct put the advantages of polymer waterproofing membrane and adhesive waterproofing membrane together,greatly improving the puncture resistance, weather resistance, self-healing, high and low temperature performance, such as a more excellent physical properties, chemical properties more stable.

2.Main Features of Polymer Adhesive Waterproofing Membrane:

•Having the rubber elasticity, excellent elongation

•Excellent sticky relay

•Safe and convenient for construction,no pollution for environment

•Excellent corrosion resistance,aging resistence

3.Polymer Adhesive Waterproofing Membrane Specification;

| Number | Test Item | Index | ||

| 1 | water absorption(%) | <0.01< span=""> | ||

| 2 | in-process shrinkage(%) | 1.55.5- | ||

| 3 | tensile strength(Mpa) | 21-37 | ||

| 4 | breaking extension(%) | >880 |

- Q: Can a waterproofing membrane be used on precast lead surfaces?

- Precast lead surfaces can benefit from the application of a waterproofing membrane. These membranes are commonly used to safeguard various types of surfaces, such as precast concrete, metal, or lead surfaces. By forming a reliable barrier against water penetration, these membranes effectively keep the underlying structure dry and well-protected. To achieve optimal results, it is crucial to thoroughly clean, dry, and remove any contaminants from the precast lead surface before applying the waterproofing membrane. This step promotes proper adhesion and enhances the membrane's ability to prevent water infiltration. For specific guidance on using a waterproofing membrane on precast lead surfaces, it is advisable to seek professional advice or consult the manufacturer's guidelines.

- Q: Can a waterproofing membrane be used on wood block surfaces?

- Certainly! Waterproofing membranes are a suitable option for safeguarding wood block surfaces. The utilization of a waterproofing membrane on wood block surfaces, like decks or wooden floors, can prove advantageous by shielding against water damage and prolonging the wood's lifespan. These membranes function as a barrier, effectively preventing water from infiltrating the wood and causing deterioration, such as rot, warping, or decay, over time. To guarantee optimal outcomes, it is crucial to select a waterproofing membrane explicitly designed for wood surfaces and adhere to the manufacturer's instructions for application. By doing so, the wood block surface can be adequately protected and maintained, ensuring its resilience and longevity.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. When applied to a surface, such as a wall or floor, the waterproofing membrane creates a barrier that prevents water or moisture from penetrating the surface. This often involves applying a coating or layer that can alter the texture or sheen of the surface. In some cases, the membrane may cause a slight color change or darken the surface. However, there are also transparent or colorless waterproofing membranes available that do not significantly alter the appearance of the surface. Ultimately, the impact on appearance will depend on the type of waterproofing membrane used and the desired aesthetic outcome.

- Q: Can a waterproofing membrane be used for a stadium seating area?

- Yes, a waterproofing membrane can be used for a stadium seating area. Waterproofing membranes are designed to provide a barrier against water penetration and are commonly used in various construction projects, including stadiums. By applying a waterproofing membrane to the seating area, it helps prevent water damage, mold growth, and deterioration caused by moisture. This ensures the longevity and durability of the seating area, protecting it from potential water-related issues.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Indeed, sloped roofs can benefit from the application of a waterproofing membrane. Utilizing a waterproofing membrane on sloped roofs is frequently advised in order to thwart water infiltration and the potential for leaks. This membrane functions as a shield, safeguarding the roof structure against water penetration and subsequent harm. Furthermore, the membrane offers defense against additional elements like UV rays, temperature fluctuations, and mechanical strains. It is vital to select a waterproofing membrane designed explicitly for sloped roofs and compatible with the roofing material to guarantee enduring protection.

- Q: Does a waterproofing membrane provide any additional structural reinforcement?

- No, a waterproofing membrane does not provide any additional structural reinforcement. The primary purpose of a waterproofing membrane is to prevent the ingress of water or moisture into a building or structure. It acts as a barrier, typically applied on the exterior surface, to keep water out and protect the underlying materials from damage caused by water. While it can enhance the durability and longevity of a structure by preventing water-related issues such as leakage, dampness, or mold growth, it does not contribute to the structural integrity or strength of the building. Structural reinforcement is typically achieved through the use of materials like steel, concrete, or other load-bearing components, which are designed to carry and distribute the weight and loads of the structure.

- Q: Can waterproofing membranes be used on utility tunnels?

- Yes, waterproofing membranes can be used on utility tunnels. Utility tunnels are often subjected to moisture and water infiltration, and using waterproofing membranes can help prevent water damage and ensure the longevity of the tunnel structure. Waterproofing membranes are designed to create a barrier between the structure and the surrounding environment, effectively preventing water from seeping into the tunnel. These membranes are typically made from materials such as bitumen or synthetic polymers, which are highly resistant to water penetration. By applying these membranes to the walls, floors, and ceilings of utility tunnels, they can effectively protect the structure from water damage, including leaks, cracks, and deterioration. Additionally, waterproofing membranes also help to maintain the integrity of utility tunnels by preventing the ingress of harmful substances such as chemicals or pollutants. Overall, using waterproofing membranes on utility tunnels is an effective method to ensure their durability and functionality in the long term.

- Q: Are waterproofing membranes suitable for indoor applications?

- Indeed, indoor applications are well-suited for waterproofing membranes. Specifically engineered to obstruct water infiltration and moisture accumulation, these membranes provide an excellent remedy for spaces vulnerable to water-induced harm, like basements, bathrooms, and kitchens. By establishing a barrier, they effectively shield the structure from water-related problems such as mold, decay, and structural deterioration, ensuring that water does not permeate floors, walls, or other surfaces. Moreover, in addition to their protective qualities, waterproofing membranes aid in regulating humidity levels, resulting in a more pleasant and healthful indoor atmosphere.

- Q: Can waterproofing membranes be used on roofs?

- Roofs can indeed benefit from the application of waterproofing membranes. These membranes serve the purpose of establishing a protective barrier that thwarts water infiltration. In order to accomplish this, the membranes are carefully crafted using materials such as modified bitumen, EPDM, PVC, or TPO, all of which boast remarkable water resistance capabilities and are proficient at sealing roofs. Their usage spans across various settings, including residential and commercial environments, where they prove to be invaluable for flat roofs, low-slope roofs, and even specific sloped roof designs. Employing multiple layers of waterproofing membranes ensures optimal safeguarding against water-related harm and significantly prolongs the roof's lifespan by averting leaks and moisture accumulation.

- Q: Can a waterproofing membrane be used on precast stone surfaces?

- Indeed, the utilization of a waterproofing membrane is viable on precast stone surfaces. Similar to all other concrete or masonry surfaces, precast stone surfaces are prone to water infiltration, which may lead to long-term damage. By applying a waterproofing membrane onto the precast stone surface, one can effectively prevent water penetration and shield the stone from moisture-related problems such as cracking, spalling, and efflorescence. This membrane establishes a barrier that hinders water seepage into the stone while still permitting it to respire and release any trapped moisture. Hence, it is crucial to select a waterproofing membrane that is compatible with the precast stone material and meticulously adhere to the manufacturer's instructions for proper application.

Send your message to us

Polymer Adhesive Modified Asphalt Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords