Self-adhesive Modified Bitumen Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Self-adhesive Modified Bitumen Waterproofing Membrane:

Self Adhesive Bitumen Waterproof Membrane

Introduction of Self-adhesive Modified Bitumen Waterproofing Membrane:

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification of Self-adhesive Modified Bitumen Waterproofing Membrane:

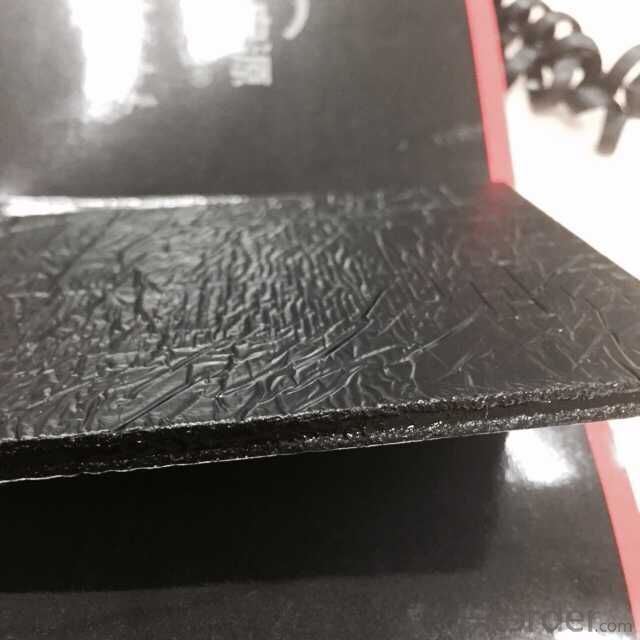

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

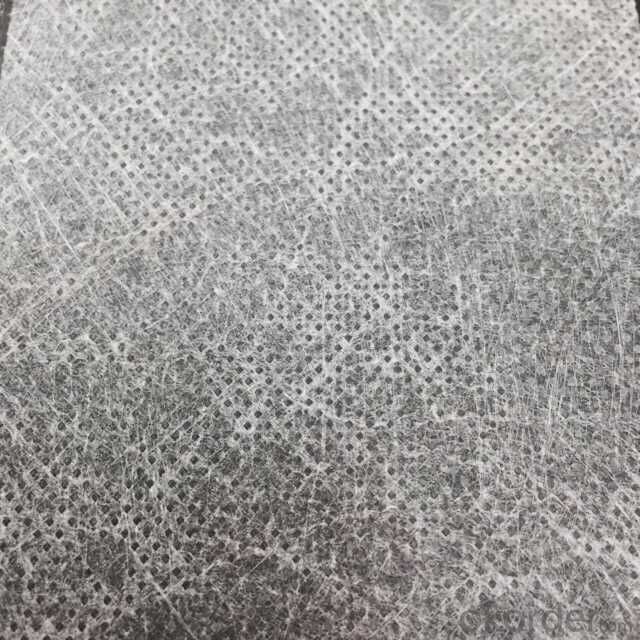

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications of Self-adhesive Modified Bitumen Waterproofing Membrane:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage of Self-adhesive Modified Bitumen Waterproofing Membrane:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

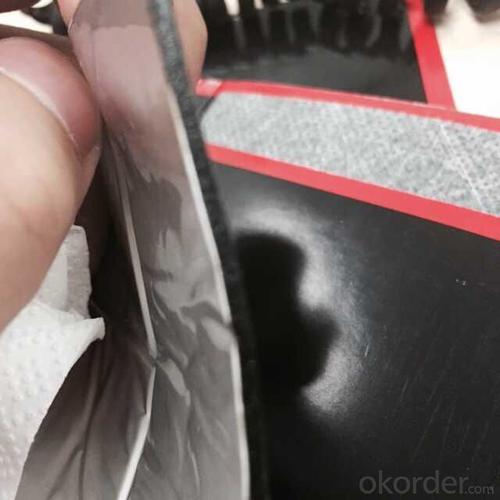

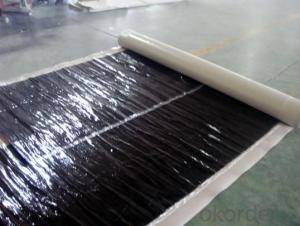

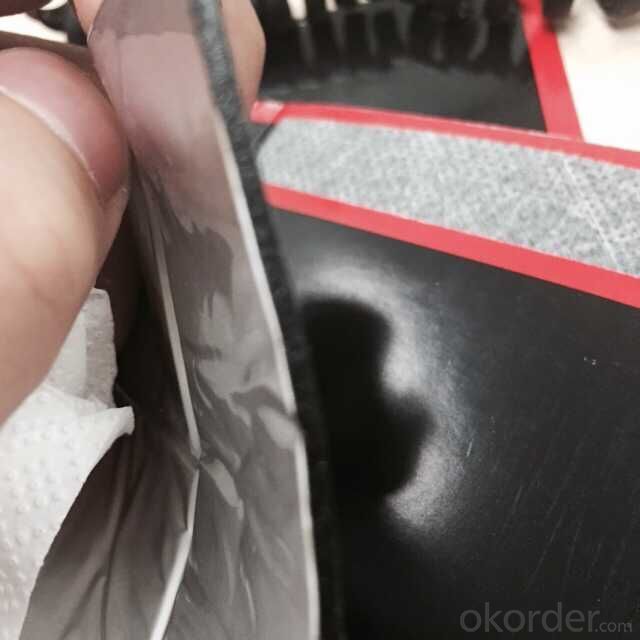

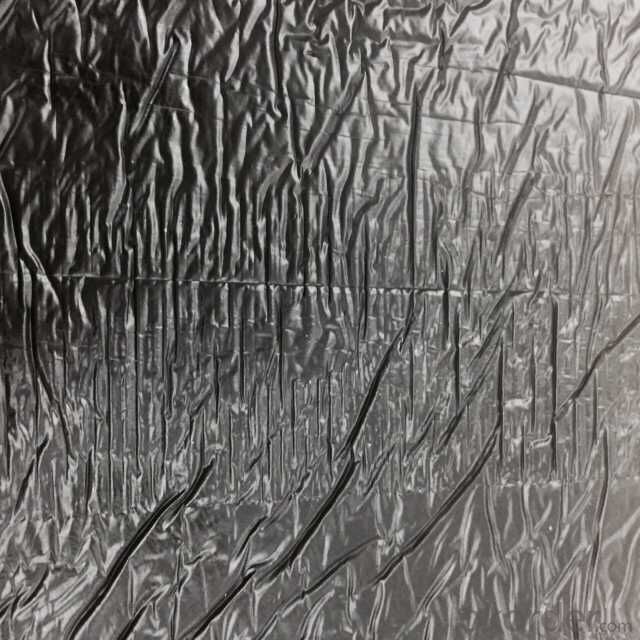

Picture of Self-adhesive Modified Bitumen Waterproofing Membrane:

Storage of Self-adhesive Modified Bitumen Waterproofing Membrane:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be installed on a concrete foundation?

- Yes, a waterproofing membrane can be installed on a concrete foundation. Waterproofing membranes are commonly used to protect concrete foundations from water damage and to prevent moisture from seeping into the building. The membrane is applied directly onto the foundation to create a barrier against water penetration.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Indeed, a waterproofing membrane proves effective in chemical or hazardous surroundings. Its purpose is to serve as a barrier against water, moisture, and other liquids, including chemicals and hazardous substances. Typically, these membranes are constructed from chemical-resistant materials like polyurethane, PVC, or modified bitumen. This composition ensures their durability and ability to withstand exposure to various chemicals without harm. Nevertheless, it is vital to choose a waterproofing membrane specifically designed for chemical or hazardous environments to guarantee compliance with necessary requirements and standards. Moreover, proper installation and maintenance play a crucial role in ensuring the long-lasting effectiveness of the waterproofing membrane in such settings.

- Q: Can a waterproofing membrane be used in fountains or water features?

- Yes, a waterproofing membrane can be used in fountains or water features. Waterproofing membranes are designed to create a barrier that prevents water from seeping through, making them ideal for applications where water containment is essential, such as fountains or water features.

- Q: Is a waterproofing membrane compatible with different types of roofing materials?

- Indeed, various roofing materials are compatible with a waterproofing membrane. This flexible solution offers versatility, making it suitable for asphalt shingles, metal roofs, concrete roofs, and even flat roofs. Its purpose is to create a barrier against water infiltration, regardless of the roofing material used. It can be directly applied to the roof's surface or used as an underlayment prior to installing the roofing material. This compatibility guarantees the effective use of the waterproofing membrane, safeguarding and prolonging the lifespan of diverse roof types.

- Q: Can a waterproofing membrane be used for a warehouse floor?

- No, a waterproofing membrane is not typically used for a warehouse floor. Instead, materials such as epoxy or concrete sealers are commonly used for warehouse floors to provide durability and resistance to heavy loads and foot traffic.

- Q: How does a waterproofing membrane handle water infiltration from below?

- A waterproofing membrane is specifically designed to handle water infiltration from below by creating a barrier that prevents moisture from seeping through. These membranes are typically made from materials such as rubber, PVC, or modified bitumen, which are inherently resistant to water penetration. When installed correctly, a waterproofing membrane is applied to the surface of a structure's foundation or basement walls, creating a continuous and impermeable layer. This membrane acts as a protective shield, preventing water from entering the structure through the foundation walls or basement floor. The membrane is typically installed in multiple layers, ensuring maximum protection against water infiltration. The layers are often overlapped and sealed together to create a seamless and watertight barrier. Additionally, the membrane may be reinforced with fabric or mesh to provide added strength and durability. In cases where there is a high water table or excessive hydrostatic pressure from the surrounding soil, the waterproofing membrane may be combined with a drainage system. This system helps to divert water away from the structure, relieving pressure and reducing the risk of water infiltration. Overall, a waterproofing membrane effectively handles water infiltration from below by creating a durable and impermeable barrier that prevents moisture from entering the structure. By installing a properly designed and installed waterproofing system, property owners can ensure long-term protection against water damage and structural deterioration.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Yes, a waterproofing membrane can be used on precast metal surfaces. The membrane acts as a protective barrier, preventing water from seeping through the metal and causing damage. It helps to maintain the integrity and longevity of the precast metal surfaces by keeping them dry and free from moisture-related issues.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Yes, a waterproofing membrane can be applied on top of existing surfaces. However, it is important to ensure that the existing surface is clean, dry, and in good condition before applying the membrane. Any cracks, holes, or damage should be repaired prior to installation. Additionally, the type of existing surface may affect the type of waterproofing membrane that can be applied. It is recommended to consult with a professional waterproofing contractor to determine the most suitable membrane for the specific surface and conditions.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. Waterproofing membranes are commonly used in tunnel construction to prevent water ingress and protect the tunnel structure from deterioration. These membranes can effectively seal the tunnel walls, ceilings, and floors, preventing water from seeping into the tunnel and potentially causing damage to the railway system or infrastructure. Waterproofing membranes are specifically designed to withstand the high-pressure conditions and constant vibrations associated with railway operations. They are typically made of durable materials such as PVC, HDPE, or modified bitumen, which provide excellent waterproofing properties and long-term durability. Furthermore, these membranes can be installed during the construction phase of the tunnel or retrofitted onto existing tunnels with minimal disruption to the railway operations. Overall, the use of waterproofing membranes is a proven and effective method to ensure the structural integrity and longevity of tunnels with railway systems.

- Q: Can a waterproofing membrane be applied in wet conditions?

- No, a waterproofing membrane cannot be applied in wet conditions. In order for the membrane to properly adhere to the surface and create an effective barrier against water, the surface must be dry and free from any moisture. Applying a waterproofing membrane in wet conditions can result in poor adhesion, which can compromise its effectiveness and lead to water leakage. It is essential to ensure that the surface is completely dry before applying the membrane to achieve the desired waterproofing results.

Send your message to us

Self-adhesive Modified Bitumen Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords