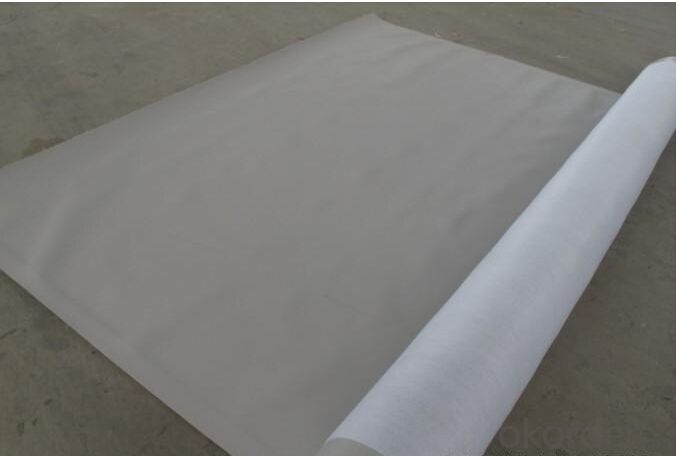

PVC Roofing Waterproof Stretch Membrane with 1.2mm Width

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Application of PVC Waterproof Membrane

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a dam?

- Certainly! A dam can employ a waterproofing membrane, a specialized material intended to obstruct the passage of water. This membrane is commonly employed in construction to establish a barrier against water intrusion. For a dam, which is an expansive structure constructed to retain water and form a reservoir, implementing an efficient waterproofing system is crucial in preventing any water leakage or infiltration. Applying a waterproofing membrane to the dam's surface offers an additional layer of defense against water penetration. Typically composed of rubber, PVC, EPDM, or bitumen, materials known for their exceptional water resistance, the membrane is layered multiple times to ensure a sturdy and long-lasting deterrent against water. It is specifically engineered to withstand the high water pressure exerted by the reservoir held behind the dam. Utilizing a waterproofing membrane preserves the dam's integrity, guaranteeing that water does not seep through the structure and cause harm to the surrounding areas. Furthermore, it aids in impeding erosion and seepage, which can weaken the dam over time. To summarize, a waterproofing membrane is indeed a viable solution for a dam, offering an effective means to ensure the dam remains watertight and structurally stable.

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Indeed, in areas with extreme temperatures, it is possible to utilize a waterproofing membrane. Numerous waterproofing membranes are specifically crafted to endure a vast spectrum of temperatures, ranging from scorching hot to freezing cold. These membranes are manufactured using materials that exhibit resistance against cracking, melting, or brittleness when exposed to extreme temperatures. Moreover, certain waterproofing membranes are specially engineered for deployment in regions with extreme temperatures, such as arctic or desert environments. To guarantee efficacy and durability, it is crucial to select a waterproofing membrane that aligns with the specific temperature range of the intended area of use.

- Q: Can a waterproofing membrane be used for underground utilities?

- Yes, a waterproofing membrane can be used for underground utilities. It provides a protective barrier against water infiltration, preventing potential damage or deterioration to the utilities.

- Q: Can a waterproofing membrane be used for disaster relief structures?

- Indeed, disaster relief structures can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to impede water infiltration and thus serve as an effective means of safeguarding temporary constructions in areas affected by calamities. Whether it be a transitory dwelling, medical establishment, or storage facility, a waterproofing membrane offers a formidable defense against precipitation, floods, and other water-related predicaments. By guaranteeing the dryness of the structure, it not only upholds the integrity of the relief edifice but also shields its inhabitants or stored provisions from water-induced harm. Moreover, waterproofing membranes are frequently lightweight, facile to install, and can be rapidly deployed during emergency scenarios, rendering them highly suitable for endeavors related to disaster relief.

- Q: Does a waterproofing membrane require any maintenance or regular inspections?

- Yes, a waterproofing membrane does require maintenance and regular inspections. While waterproofing membranes are designed to be durable and long-lasting, they are not immune to wear and tear or potential damages. Regular inspections are essential to identify any signs of damage or deterioration, which can then be addressed promptly to prevent further issues. Maintenance activities may include cleaning the membrane to remove dirt or debris, repairing any visible cracks or tears, and ensuring proper drainage and water flow. Additionally, it is advisable to follow the manufacturer's guidelines for maintenance and schedule professional inspections periodically to ensure the effectiveness and longevity of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for a garden pond?

- Yes, a waterproofing membrane can be used for a garden pond. Waterproofing membranes are designed to create a barrier against water leakage, making them suitable for lining and sealing garden ponds to prevent water from seeping into the surrounding soil.

- Q: Can a waterproofing membrane be used on tunnels?

- Tunnels, being exposed to high moisture levels, groundwater infiltration, and potential leaks, necessitate the use of a waterproofing membrane. This is crucial for safeguarding their long-term structural integrity and preventing water damage. In tunnel construction, waterproofing membranes are widely employed as they effectively prevent water penetration and act as a reliable moisture barrier. These membranes are specifically designed to be durable, flexible, and resistant to different environmental conditions, making them suitable for tunnel application. By applying these membranes to the tunnel walls, roof, and floor, a waterproof seal is created, ensuring the tunnel remains dry and protected against issues such as corrosion, deterioration, and mold growth caused by water. Moreover, the use of waterproofing membranes not only helps reduce maintenance costs but also extends the lifespan of the tunnel infrastructure.

- Q: Can a waterproofing membrane be used in planters or garden beds?

- Yes, a waterproofing membrane can be used in planters or garden beds to prevent water leakage and protect the surrounding areas. It helps to retain moisture in the soil and prevents water damage to the planter or garden bed structure.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Yes, a waterproofing membrane can help prevent efflorescence or mineral deposits on surfaces. The membrane acts as a barrier, preventing water from entering the surface and carrying dissolved minerals or salts that cause efflorescence. By keeping the surface dry, the membrane helps to minimize the formation of mineral deposits.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can be used in schools or educational buildings. Waterproofing membranes are commonly used in these types of buildings to protect them from water damage and leakage. By preventing water infiltration, a waterproofing membrane helps maintain a safe and healthy environment for students and staff, preserving the structural integrity of the building and reducing maintenance costs in the long run.

Send your message to us

PVC Roofing Waterproof Stretch Membrane with 1.2mm Width

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords