PVC Polyvinyl Chloride Roofing Waterproof Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

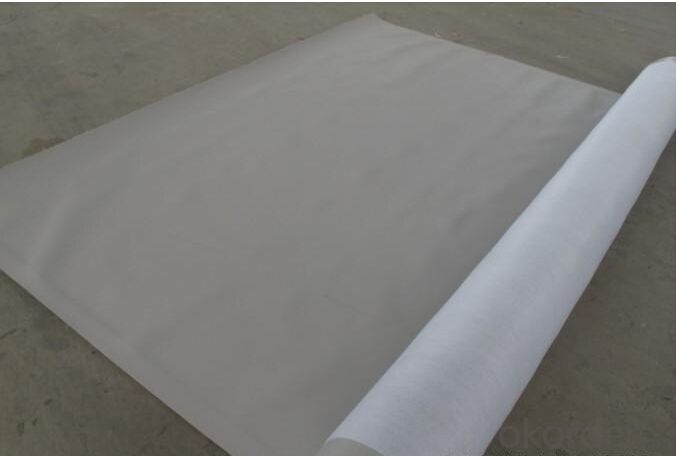

Introduction of PVC Waterproof Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane

No. | Item | Index | |||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10.0 | - | - | 10.0 | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

Application of PVC Waterproof Membrane

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to fire?

- Yes, waterproofing membranes can be resistant to fire. Many waterproofing membranes are designed to have fire-resistant properties to ensure the safety of the structure. These membranes are typically made of materials that have high fire ratings and are able to resist the spread of flames. Fire-resistant waterproofing membranes are commonly used in areas where fire safety is a concern, such as commercial buildings, high-rise structures, and industrial facilities. Additionally, these membranes are often tested and certified by relevant authorities to ensure their fire resistance capabilities. However, it is important to note that not all waterproofing membranes are fire-resistant, so it is crucial to select the appropriate membrane based on the specific fire safety requirements of the project.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on wood surfaces. First and foremost, it is important to ensure that the wood surface is clean, dry, and free from any dirt, dust, or debris. This will help to create a proper bond between the wood and the waterproofing membrane. Additionally, it is crucial to choose a waterproofing membrane that is specifically designed for wood surfaces. There are different types of membranes available, such as liquid-applied membranes or sheet membranes, so selecting the right one is essential. Before applying the membrane, it is advisable to prime the wood surface with a suitable primer. This will help to enhance the adhesion of the membrane and provide a more durable and long-lasting waterproofing solution. It is also important to consider the climate and weather conditions in the area where the wood surface is located. If the area is prone to extreme temperatures or heavy rainfall, it is recommended to choose a waterproofing membrane that can withstand these conditions and provide adequate protection. Furthermore, proper installation techniques should be followed to ensure the membrane is applied correctly. This may involve rolling or brushing the membrane onto the wood surface, as per the manufacturer's instructions. It is crucial to pay attention to details such as seams, corners, and edges to ensure a watertight seal. Regular maintenance and inspection are essential for the longevity of the waterproofing membrane on wood surfaces. It is important to check for any signs of damage, such as cracks or peeling, and address them promptly to prevent water infiltration and potential damage to the wood. In summary, when installing a waterproofing membrane on wood surfaces, it is crucial to prepare the surface properly, choose the right type of membrane, consider the climate and weather conditions, follow proper installation techniques, and perform regular maintenance and inspection. By doing so, you can effectively protect the wood surface from water damage and ensure its longevity.

- Q: Can a waterproofing membrane be used for seawalls or bulkheads?

- Seawalls or bulkheads can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier against water, and they can be applied to various structures, including seawalls and bulkheads. The materials used for these membranes, such as bitumen, rubber, PVC, or polyurethane, are known for their excellent resistance to water and their ability to maintain the integrity of the wall or bulkhead. By applying the membrane to the surface of the structure, a continuous and durable waterproof layer is formed, effectively preventing water from seeping through. This protective layer helps safeguard the seawall or bulkhead from erosion, corrosion, and other types of damage caused by exposure to seawater. Moreover, waterproofing membranes offer additional advantages, including increased durability, improved aesthetics, and enhanced resistance to UV rays and chemicals. In conclusion, the use of a waterproofing membrane is a reliable solution for ensuring the long-term performance and durability of seawalls and bulkheads in marine environments.

- Q: Can a waterproofing membrane be applied on top of roofing materials?

- Applying a waterproofing membrane on top of roofing materials is a common practice in the construction industry. This is crucial for areas with heavy rainfall or extreme weather conditions, as it provides an extra layer of protection against water infiltration. The waterproofing membrane acts as a barrier, preventing water from seeping through the roof and causing damage to the underlying structure. It is worth noting that depending on the type of membrane used, it can also improve insulation and enhance the energy efficiency of the building. To ensure the effectiveness and longevity of the waterproofing system, it is important to follow proper installation techniques and adhere to the manufacturer's guidelines. It is advisable to consult with a professional roofing contractor or waterproofing specialist to determine the most suitable membrane and installation method for your specific roofing materials and conditions.

- Q: Can a waterproofing membrane be used for medical facilities?

- Yes, a waterproofing membrane can be used for medical facilities. Waterproofing membranes are commonly used in construction to prevent water ingress and protect buildings from moisture damage. In medical facilities, where cleanliness and hygiene are crucial, waterproofing membranes can be used to create a moisture barrier, preventing water and moisture from seeping into walls and floors, which can lead to mold growth or damage to sensitive medical equipment. Additionally, waterproofing membranes can aid in maintaining a sterile environment by preventing the growth of bacteria or other pathogens that could be present in damp conditions.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Yes, a waterproofing membrane is resistant to saltwater or salt damage. Its composition and design make it highly durable and capable of withstanding the corrosive effects of saltwater, ensuring long-term protection against leaks and seepage.

- Q: Are waterproofing membranes resistant to hydraulic oils?

- No, waterproofing membranes are not typically resistant to hydraulic oils.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: How does a waterproofing membrane handle settlement of adjacent structures?

- A waterproofing membrane is designed to handle settlement of adjacent structures in a few different ways. Firstly, a high-quality waterproofing membrane is often flexible and elastic, allowing it to stretch and move with the settling of the adjacent structures. This flexibility helps to prevent the membrane from cracking or tearing under the stress of settlement. Additionally, some waterproofing membranes are reinforced with materials such as fiberglass or polyester to provide added strength and durability. These reinforcements help to distribute the stress caused by settlement more evenly across the membrane, reducing the likelihood of damage. Furthermore, waterproofing membranes are typically applied in multiple layers to provide redundancy and added protection. This means that even if one layer of the membrane is compromised due to settlement, there are additional layers underneath that can continue to provide waterproofing. Lastly, proper installation and maintenance of the waterproofing membrane is crucial in ensuring its ability to handle settlement. A skilled contractor will take into account the potential for settlement and will properly prepare the substrate and apply the membrane to minimize the risk of damage. In summary, a waterproofing membrane can handle settlement of adjacent structures through its flexibility, reinforcements, multiple layers, and proper installation. These features work together to ensure that the membrane remains intact and continues to provide effective waterproofing, even in the presence of settlement.

- Q: Can a waterproofing membrane be used for a stadium roof structure?

- Yes, a waterproofing membrane can be used for a stadium roof structure. A waterproofing membrane is a protective layer that prevents water from penetrating the roof and causing damage. It is typically made of materials such as rubber or synthetic polymers that are resistant to water. In the case of a stadium roof structure, a waterproofing membrane can be used to ensure that the roof remains watertight and prevents any leaks or water damage. This is particularly important for stadiums that have open-air or retractable roofs, as they are exposed to the elements and are more susceptible to water infiltration. A waterproofing membrane can be applied to various types of stadium roof structures, including metal, concrete, or even fabric roofs. It is typically installed beneath the roofing material, acting as a protective barrier against water. By preventing water from seeping into the roof, the membrane helps to extend the lifespan of the roof and protect the interior of the stadium from water damage. Additionally, a waterproofing membrane can also provide other benefits for a stadium roof structure. It can help to improve energy efficiency by reducing heat loss or gain through the roof. Some membranes also offer UV resistance, which helps to protect the roof from damaging ultraviolet rays. Overall, using a waterproofing membrane for a stadium roof structure is a practical and effective solution to ensure the roof remains watertight, durable, and protected from water damage.

Send your message to us

PVC Polyvinyl Chloride Roofing Waterproof Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords