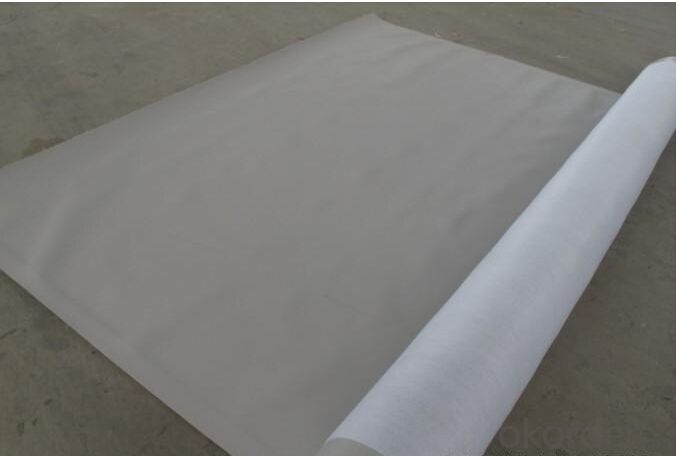

PVC Roofing Waterproof Membrane/Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane. The raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Is a waterproofing membrane resistant to rodent or insect infestation?

- A waterproofing membrane has the ability to resist infestation from rodents or insects. Most waterproofing membranes are constructed using materials that rodents or insects find unappealing, such as bitumen or synthetic polymers. Furthermore, these membranes are typically installed in a manner that eliminates any gaps or openings through which pests could enter. However, it should be noted that no waterproofing system is completely impervious to infestation. If there are existing entry points or if the membrane is damaged or improperly installed, rodents or insects may still be capable of breaching the waterproofing system. Regular inspection and maintenance are essential to ensure the integrity of the waterproofing membrane and to prevent any infestation from occurring.

- Q: Can a waterproofing membrane prevent water leakage in basements?

- Yes, a waterproofing membrane can effectively prevent water leakage in basements. The membrane acts as a barrier, preventing water from seeping through the foundation walls or basement floors. It is designed to withstand hydrostatic pressure and provide a durable and long-lasting solution to keep basements dry and protected from water damage.

- Q: Polyethylene polypropylene waterproofing membrane forming. Secondary molding, what does it mean? How to distinguish?

- Polyethylene polypropylene waterproofing membrane from the middle of the "polyethylene" chip, two-sided composite "polypropylene non-woven" made, one method is in the extrusion production of polyethylene film at the same time, when the polyethylene is still in a soft state , In the upper and lower sides of the membrane composite polypropylene non-woven, the temperature can not be too high and polypropylene buried too much, the temperature can not be too low, otherwise the sticky on the sticky.

- Q: Can a waterproofing membrane be used for a swimming pool deck?

- Yes, a waterproofing membrane can be used for a swimming pool deck. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting the pool deck from water damage and ensuring its longevity.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to handle movement of a building caused by settling or seismic activity by providing flexibility and elasticity. It can accommodate small shifts and vibrations without cracking or breaking, ensuring that the waterproof barrier remains intact. The membrane's ability to stretch and contract helps it to adapt to the movement of the structure, preventing water intrusion and maintaining its effectiveness in safeguarding the building against moisture damage.

- Q: Can a waterproofing membrane be used in rooftop gardens or green roofs?

- Yes, a waterproofing membrane can be used in rooftop gardens or green roofs. In fact, it is essential to have a reliable waterproofing system in place to protect the structure beneath the garden or roof from water damage. A waterproofing membrane acts as a barrier, preventing water from seeping into the building or causing structural issues. It is typically installed beneath the soil or growing medium of the rooftop garden or green roof, ensuring that water is properly drained and doesn't compromise the integrity of the building. Additionally, these membranes are designed to withstand the exposure to UV rays, temperature fluctuations, and root penetration, making them suitable for long-term use in rooftop gardens or green roofs.

- Q: Can a waterproofing membrane be installed in cold weather?

- Installing a waterproofing membrane in cold weather can present challenges. The freezing temperatures can affect the adhesion and curing process, potentially impacting the membrane's effectiveness. Therefore, it is important to observe the manufacturer's instructions and take extra precautions when working in cold weather conditions. To ensure successful installation, it is advisable to use a waterproofing membrane specifically designed for cold weather. These membranes are formulated with additives that enhance their adhesion and flexibility in low temperatures. Moreover, the temperature of the substrate should be considered during installation. It is crucial for the surface where the membrane will be applied to be above freezing temperature to ensure proper adhesion. In cases where the substrate temperature is too low, external heating methods like heat guns or warm air blowers may be necessary to warm the surface and achieve proper adhesion. Additionally, proper storage of the membrane prior to installation is vital in cold weather conditions. To prevent brittleness or loss of flexibility, the membrane should be stored in a warm environment. In conclusion, while it is possible to install a waterproofing membrane in cold weather, it is essential to take necessary precautions, use membranes designed for cold weather, and adhere to the manufacturer's guidelines to ensure proper adhesion and effectiveness.

- Q: How does a waterproofing membrane handle moisture from the ground?

- A waterproofing membrane is designed to effectively handle moisture from the ground by creating a barrier that prevents water infiltration. It is typically made from materials such as rubber, bitumen, or modified asphalt, which are impermeable to water. When installed correctly, the membrane forms a continuous, watertight layer that prevents water from seeping through the foundation or walls. The membrane is typically installed on the exterior side of a building's foundation, where it acts as a protective barrier against groundwater. It is applied directly onto the concrete or masonry surface, creating a seamless and durable waterproofing layer. The membrane is then covered with a protective layer, such as soil or backfill, to ensure its long-term integrity. In addition to its impermeable properties, a waterproofing membrane also incorporates features that allow it to handle moisture effectively. For instance, it may have built-in channels or dimples that allow water to drain away from the foundation, preventing the accumulation of hydrostatic pressure. Some membranes also have self-healing properties, meaning they can seal small punctures or cracks that may occur over time. Overall, a properly installed waterproofing membrane acts as a reliable barrier against moisture from the ground. It helps protect the structure from water damage, prevents the growth of mold and mildew, and maintains a dry and healthy indoor environment. However, it is essential to ensure that the membrane is installed correctly by following the manufacturer's guidelines and working with experienced professionals to ensure its effectiveness.

- Q: Can a waterproofing membrane be installed on curved surfaces?

- Yes, a waterproofing membrane can be installed on curved surfaces. There are various types of waterproofing membranes available in the market that are specifically designed to cater to different surface shapes and conditions. These membranes can be flexible and easily molded to fit curved surfaces, ensuring effective waterproofing even on complex structures. However, it is important to consult with a professional or manufacturer to determine the most suitable membrane and installation technique for your specific curved surface to ensure proper adhesion and long-lasting waterproofing.

Send your message to us

PVC Roofing Waterproof Membrane/Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords