PVC Membrane Waterproof /Waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

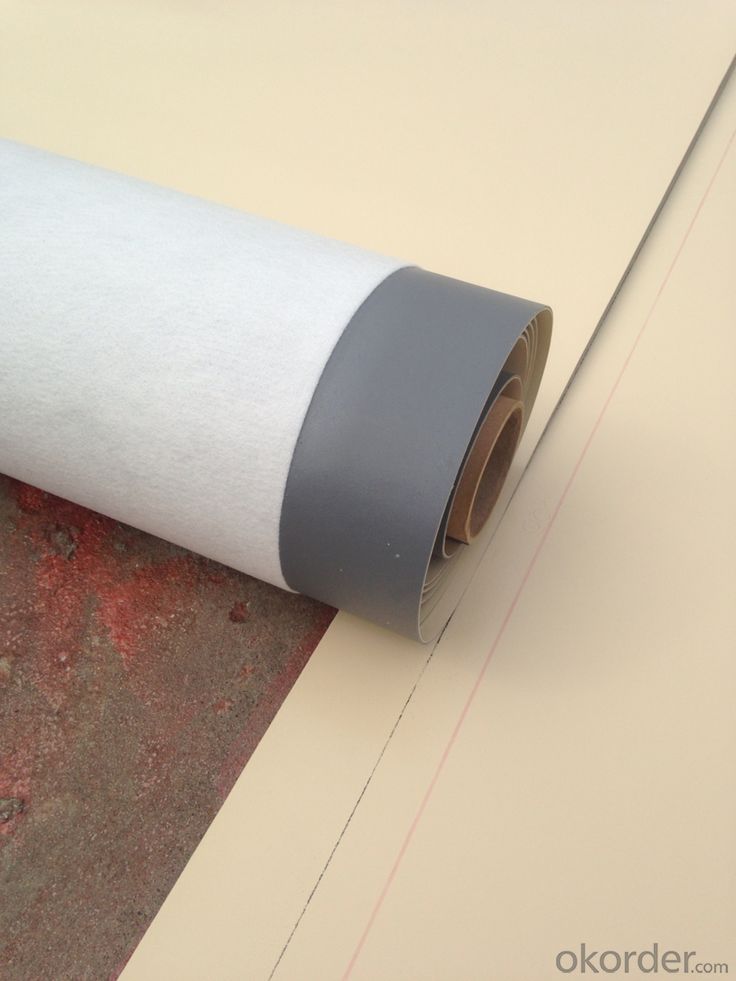

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters:

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Yes, a waterproofing membrane can definitely be used in conjunction with tile or stone installations. In fact, it is highly recommended to use a waterproofing membrane in wet areas such as bathrooms, showers, and kitchen backsplashes to prevent water damage and moisture penetration. A waterproofing membrane acts as a barrier that prevents water from seeping through the tile or stone and reaching the underlying layers, such as the subfloor or wall. It helps to protect the structure and prolong the lifespan of the installation. There are various types of waterproofing membranes available, including liquid-applied membranes, sheet membranes, and fabric membranes. These membranes can be applied to the substrate before the tile or stone is installed, creating a waterproof layer that ensures the area remains dry and free from water-related issues. Using a waterproofing membrane not only provides protection against water damage but also helps to prevent the growth of mold and mildew, which can be harmful to both the installation and the health of the occupants. It is important to note that the proper installation of the waterproofing membrane is crucial for its effectiveness. It should be applied according to manufacturer guidelines and best practices to ensure a tight seal and complete coverage. Overall, incorporating a waterproofing membrane with tile or stone installations is a wise choice, as it enhances the durability and longevity of the project while providing peace of mind against potential water damage.

- Q: How are waterproofing membranes installed?

- To safeguard buildings and structures from water damage, the application of waterproofing membranes is essential. Typically, the installation process involves multiple steps. Initially, the designated surface must be adequately prepared. This entails cleansing the surface and eliminating any debris or loose materials. Ensuring the surface is smooth and devoid of irregularities or cracks is of utmost importance. Following this, a primer is administered to the surface. This aids in establishing a robust bond between the membrane and the surface. Typically, a brush or roller is employed to apply the primer, and it is crucial to allow it to completely dry before proceeding to the subsequent step. Once the surface is primed, the waterproofing membrane can be installed. Various types of membranes are available, including sheet membranes, liquid membranes, and peel-and-stick membranes. The selection of the membrane type depends on the project's requirements and the surface being waterproofed. For sheet membranes, the material is typically unrolled and carefully positioned over the primed surface. It is crucial to ensure the proper alignment of the membrane, devoid of any wrinkles or air pockets. Subsequently, the membrane is firmly pressed down to establish a robust bond with the surface. Liquid membranes are usually applied using a brush or roller. The liquid is evenly spread over the primed surface, and multiple coats may be applied to ensure a comprehensive and effective waterproofing layer. Each coat must be allowed to dry before proceeding to the next. Peel-and-stick membranes are the simplest to install. The backing is peeled off the membrane, and it is meticulously pressed onto the primed surface. The adhesive on the membrane's back establishes a strong bond with the surface. Once the membrane is installed, any seams or joints must be adequately sealed. This is typically achieved using waterproofing tape or sealant. The objective is to create a continuous and watertight barrier to prevent any water from penetrating. Overall, the installation process for waterproofing membranes necessitates meticulous preparation, accurate application, and attention to detail. It is crucial to adhere to the manufacturer's instructions and utilize appropriate materials and techniques for the specific membrane being installed. By doing so, a dependable and efficient waterproofing system can be established, safeguarding the building or structure from water damage.

- Q: Can a waterproofing membrane be used in conjunction with landscaping or hardscaping projects?

- Yes, a waterproofing membrane can be used in conjunction with landscaping or hardscaping projects. It can provide an additional layer of protection and help prevent water damage to structures or areas where landscaping or hardscaping is being done.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. These facilities often require protection against water infiltration and leakage due to the presence of large amounts of water and potentially corrosive substances. A waterproofing membrane is a versatile solution that can provide a barrier against water penetration, helping to prevent damage to the structure and ensure the proper functioning of the facility. It can be applied to various areas such as walls, floors, roofs, and tanks, helping to maintain a watertight environment and prolong the lifespan of the facility. Additionally, some waterproofing membranes are specifically designed to withstand harsh chemicals, making them suitable for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces of a structure. Waterproofing membranes are designed to create a barrier that prevents water or moisture from penetrating into the structure, whether it is applied on the inside or outside. On the interior, a waterproofing membrane can be used to protect basements, crawl spaces, or other areas prone to moisture intrusion. This helps to prevent water damage, mold growth, and other issues that can arise from excess moisture in these spaces. On the exterior, a waterproofing membrane is commonly used to protect the foundation, walls, and other structural elements from water infiltration. This is especially important in areas with heavy rainfall or where the water table is high. By applying a waterproofing membrane on the exterior, it helps to keep the structure dry and prevents potential damage caused by water seepage. It is important to note that different types of waterproofing membranes are available for specific applications, so the selection of the appropriate membrane will depend on the specific requirements of the project.

- Q: Can a waterproofing membrane be used in kitchens?

- Yes, a waterproofing membrane can be used in kitchens. Waterproofing membranes are commonly used in areas prone to moisture, such as bathrooms and kitchens, to prevent water damage and leakage. They can be applied to various surfaces, including floors and walls, to create a waterproof barrier and protect against water infiltration. By using a waterproofing membrane in kitchens, one can ensure the longevity and durability of the space while preventing potential water-related issues.

- Q: Can a waterproofing membrane be used for a warehouse?

- Yes, a waterproofing membrane can be used for a warehouse. A waterproofing membrane is designed to protect surfaces from water penetration, making it a suitable solution for warehouses that require protection against moisture, leaks, and potential water damage.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. The membrane acts as a protective barrier, preventing water penetration and ensuring the insulation remains dry and functional.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Yes, a waterproofing membrane can be used in basements and foundations. Waterproofing membranes are specifically designed to prevent the penetration of water and moisture, making them an effective solution for protecting basements and foundations from water damage.

- Q: Can a waterproofing membrane be used for a planter box waterproofing?

- Yes, a waterproofing membrane can be used for planter box waterproofing. A waterproofing membrane is designed to create a barrier against water and moisture, preventing it from seeping through the surface it is applied to. This makes it an ideal choice for planter box waterproofing, as it helps to protect the structure of the planter box and prevent water damage. The membrane can be applied to the interior of the box, creating a watertight seal that prevents water from leaking out or causing damage to the surrounding surfaces. Additionally, a waterproofing membrane can also help to extend the lifespan of the planter box by preventing the growth of mold or mildew, which can be caused by excess moisture. Overall, using a waterproofing membrane for planter box waterproofing is a practical and effective solution to ensure the longevity and durability of the planter box.

Send your message to us

PVC Membrane Waterproof /Waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords