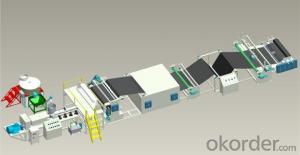

PE Waterproof Machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery Of PE Waterproof Rolls Plastic Machinery

| Packaging Detail: | Wood case or PE Film |

| Delivery Detail: | Within 45 workdays |

Specifications Of PE Waterproof Rolls Plastic Machinery

1.New energy saving tech.

2.High efficiency extruder

3.Famous electrical component

Main technical parameters Of PE Waterproof Rolls Plastic Machinery

Type |

SFJ-1400 |

SFJ-2200 |

SFJ-2500 |

Main motor |

SJ-90 |

SJ-120 |

SJ-150 |

Screw diameter(mm) |

90 |

120 |

150 |

L/D ratio |

25:1/30:1 |

25:1/30:1 |

25:1/30:1 |

Motor power(kw) |

55 |

90 |

132 |

Control method | Frequency covertion | ||

Move method | Whole move | ||

Width(mm) |

1000 |

1500 |

2000 |

Quencher roller cooled medium | Water | ||

Asphalt heating medium | Conduct heat oil | ||

Total power(kw) |

82 |

156 |

228 |

- Q: What does blister machine do?

- Plastic machine is mainly divided into two categories, one is used for production of billboards, a film for sliding door

- Q: What what plastic products should use "rolling, extrusion, blow molding, pressing, plastic, rotational molding and injection"?

- 4, pressing molding, the use of: often used cotton, glass cloth, paper, asbestos cloth, etc., the resin has phenolic, epoxy, unsaturated polyester, and some thermoplastic resin.5, the use of plastic molding, the main principle is: the flat hard plastic sheet is heated to soften the vacuum adsorption on the surface of the mold, cooling after molding, widely used in plastic packaging, lighting, advertising, decoration and other industries6, rotational molding, usage: rotational used are polyethylene, polyamide, polycarbonate, polystyrene modified cellulose and plastic etc..7, use: injection molding, injection molding is suitable for almost all of the thermoplastic plastic injection molding, molding cycle is short (seconds to minutes), the quality of molding products from a few grams to tens of kilograms, can form a complex shape, accurate size, with metal or non metal insert molding the.

- Q: What brand is good blister machine?

- Do you mean that the machine that has a blister machine has a brand? I don't know. I know what plastic material is made of.

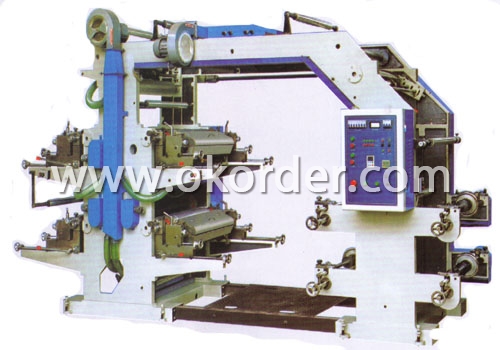

- Q: For example, three roller calender, the size of the three roller models are the same, or is there a big difference?

- Are the same, that is, there is a spindle, two transmission shaft, 3 roller diameter is 18 inches

- Q: How to choose an automatic plastic suction machine?

- 2. price. General plastic suction machine if the price is less than 100 thousand, mostly low matching or semi-automatic. Really good automatic plastic suction machine import configuration, high-quality steel, high-quality assembly master, these costs are not less than 100 thousand, the price is about 150 thousand. Petty gains, no good goods.

- Q: What is the difference between injection molding machine and plastic suction machine?

- The injection molding machine is processing by extrusion, and the product is plastic absorbing machine by vacuum processing.

- Q: The processing technology of PVC calendering film?

- First of all, ST300 smooth powder to solve the PVC colored film industry generally exist ink adhesion, yellowing, transparency and other issues, such as advertising films, crystal films, sheets, packaging film, etc..

- Q: Blister machine rules and matters needing attention

- 4, operators will be plastic packaging, paperboard, bakelite mold, counterclockwise rotation mode, the machine in debugging, automatic packing seal.5, the entire system and source are closed after the job is done.The above information comes from Nanyang machinery factory in Longgang District of Shenzhen city. I hope it can help you

- Q: How are rubber and plastic calender classified? What are the features and uses?

- Two, according to the classification of characteristics, according to various plastic physical and chemical characteristics, plastic can be divided into thermosetting plastic and hot plastic plastic two types. (1) thermoplastic plastics thermoplastics (Thermo plastics): refers to the heat will melt, can flow into a mold cooling after molding, and then heated and melted plastic; can be used for heating and cooling, which produces a reversible change (liquid vs. solid), is called a physical change. General purpose thermoplastic plastic, its continuous use temperature below 100 degrees Celsius, polyethylene, polyvinyl chloride, polypropylene, polystyrene and called the four major plastic. Thermoplastic plastics are divided into hydrocarbons, polar genes of vinyl, engineering, cellulose and other types. Become soft when heated, harden when cooled, soften and harden repeatedly, and maintain a definite shape. Soluble in a certain solvent; having a soluble property. Thermoplastic plastics with excellent electrical insulation, especially polytetrafluoroethylene (PTFE), polystyrene (PS), polyethylene (PE), polypropylene (PP) has a dielectric constant and very low dielectric loss dielectric, is suitable for high frequency and high voltage insulation materials. Thermoplastics are easy to shape, but they have low heat resistance and are easy to creep. The creep degree varies with the load, the temperature, the solvent and the humidity. In order to overcome the weakness of thermoplastics, meet the need of the application of space technology, new energy development and other fields, all the countries in the development of heat-resistant resin melt molding, such as polyetheretherketone (PEEK), polyethersulfone (PES), polysulfone (PASU) and polyphenylene sulfide (PPS) etc..

- Q: Which manufacturer does calendering machine do better? Be anxious?

- What do you look at the main rolling mill production process, what is the Suzhou dongfulai, doing good, they are mainly based on the customization process

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 1 Million |

| Main Markets | East European, Russia, North American, Southen America, East Asia, Africa |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 5~6 |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 6,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

PE Waterproof Machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords