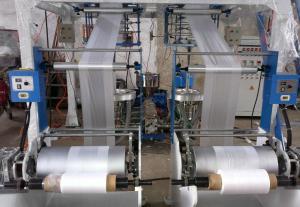

High Speed Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of High Speed Blown Film Machine

The crew extruder, screw barrel, are made of high quality alloy steel

Usage of High Speed Blown Film Machine

The crew extruder, screw barrel, are made of high quality alloy steel, tight nitriding treatment and precision machining, with the best hardness and corrosion resistance, special designed screw high output, good plasticizing . Suitable for blowing low density polyethylene ( LDPE ) and high density polyethylene ( HDPE ) linear low density polyethylene ( LLDPE ) etc. plastic film, widely used in food, clothing, garbage bags, vest bags and other civil and industrial packaging.

Specification of High Speed Blown Film Machine

Model | RHT-50FM600 | RHT-55FM800 | RHT-60FM1000 |

Screw DIA | 50mm | 55 mm | 60 mm |

Screw L/D Ratio | L/D28:1 | L/D28:1 | L/D28:1 |

Screw Rotary speed | 10-120r/min | 10-120r/min | 10-120r/min |

Master Power | 18.5Kw | 22Kw | 30Kw |

Extryded Volume | 30-60kg/h | 40-80kg/h | 50-100kg/h |

Film Max folding Dia | 600mm | 800mm | 1000mm |

Single Film Thickness | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm |

Sub-master Machine Lift Scope | 800mm | 1000mm | 1200mm |

Total Power | 28kw | 36kw | 42kw |

Weight | 2600kg | 3000kg | 3500kg |

Overall Dimension(LXWXH | 4699*2600*4000mm | 4800*2800*4300mm | 4800*3000*4800mm |

- Q: PVC blow molding and rolling film difference

- Blow molding: a method of forming a hollow product by expanding a hot melt parison closed in a mold by means of a gas pressure,

- Q: What what plastic products should use "rolling, extrusion, blow molding, pressing, plastic, rotational molding and injection"?

- Calendering, extrusion, blow molding, pressing, plastic, plastic and plastic injection, use the following:1, extrusion molding, the use of: extrusion method is mainly used for thermoplastic molding, can also be used for certain thermosetting plastics.Such as tubes, rods, wires, plates, films, wires, cables, cladding, etc..2, rolling molding, the use of: Ting used for films, sheets, artificial leather and other coating products.3, blow molding, the use of: mainly used in a variety of packaging containers and pipe film manufacturing. All the melt index was 0.04 ~ 1.12 are excellent materials of hollow blow molding, such as polyethylene, polypropylene, PVC, polystyrene, thermoplastic polyester, polycarbonate, polyamide, polyacetal resin and cellulose acetate, which is used widely in polyethylene.

- Q: What brand is good blister machine?

- Some people like bamboo chopsticks, some people like wood chopsticks, and there is a penny for each other, and decide for yourself

- Q: For example, three roller calender, the size of the three roller models are the same, or is there a big difference?

- Are the same, that is, there is a spindle, two transmission shaft, 3 roller diameter is 18 inches

- Q: How to choose an automatic plastic suction machine?

- 1. accessories. The main configuration of the JUNSAI machine is its soul, and buyers must not ignore the configuration simply by drawing cheap. Many amateurs buy the machine back, found that many of the configuration is not installed, and it will be more expensive to return. Contrast is what brand accessories, whether or not with water cooler, vacuum pump, general air compressor is with their own. Jun Jing competition from Japan Toshiba procurement of electronic parts, absolute quality assurance. Of course, the import configuration is more stable than the domestic configuration.

- Q: What is the difference between injection molding machine and plastic suction machine?

- The work works just the opposite. Hope to adopt!

- Q: I want to buy a new fully automatic blister machine. I wonder if that made brand is good What's the price? How many pieces can be produced in a day with a 1000*450 thick plastic suction disk?

- Generally 10 tens of thousands, you may be using PS! See how thick you use PS, and the high end of the mold, the size of the product are related.

- Q: The processing technology of PVC calendering film?

- First of all, ST300 smooth powder to solve the PVC colored film industry generally exist ink adhesion, yellowing, transparency and other issues, such as advertising films, crystal films, sheets, packaging film, etc..

- Q: Blister machine rules and matters needing attention

- 4, operators will be plastic packaging, paperboard, bakelite mold, counterclockwise rotation mode, the machine in debugging, automatic packing seal.5, the entire system and source are closed after the job is done.The above information comes from Nanyang machinery factory in Longgang District of Shenzhen city. I hope it can help you

- Q: How are rubber and plastic calender classified? What are the features and uses?

- Two, according to the classification of characteristics, according to various plastic physical and chemical characteristics, plastic can be divided into thermosetting plastic and hot plastic plastic two types. (1) thermoplastic plastics thermoplastics (Thermo plastics): refers to the heat will melt, can flow into a mold cooling after molding, and then heated and melted plastic; can be used for heating and cooling, which produces a reversible change (liquid vs. solid), is called a physical change. General purpose thermoplastic plastic, its continuous use temperature below 100 degrees Celsius, polyethylene, polyvinyl chloride, polypropylene, polystyrene and called the four major plastic. Thermoplastic plastics are divided into hydrocarbons, polar genes of vinyl, engineering, cellulose and other types. Become soft when heated, harden when cooled, soften and harden repeatedly, and maintain a definite shape. Soluble in a certain solvent; having a soluble property. Thermoplastic plastics with excellent electrical insulation, especially polytetrafluoroethylene (PTFE), polystyrene (PS), polyethylene (PE), polypropylene (PP) has a dielectric constant and very low dielectric loss dielectric, is suitable for high frequency and high voltage insulation materials. Thermoplastics are easy to shape, but they have low heat resistance and are easy to creep. The creep degree varies with the load, the temperature, the solvent and the humidity. In order to overcome the weakness of thermoplastics, meet the need of the application of space technology, new energy development and other fields, all the countries in the development of heat-resistant resin melt molding, such as polyetheretherketone (PEEK), polyethersulfone (PES), polysulfone (PASU) and polyphenylene sulfide (PPS) etc..

1. Manufacturer Overview

| Location | Zhejiang, China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia Domestic Market |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo Port,Shanghai Port |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

High Speed Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords